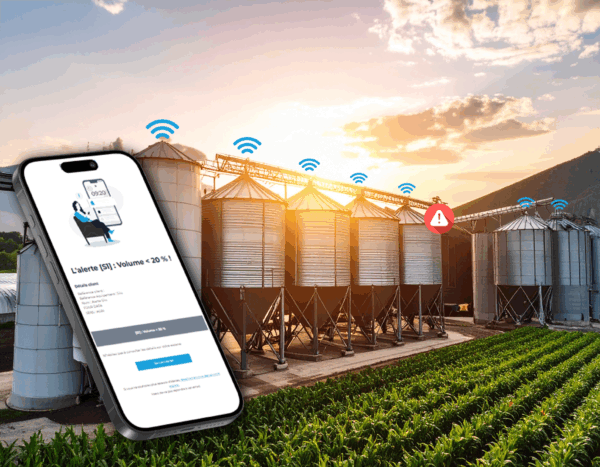

Level sensors for silos and tanks in agriculture and industry

Efficiently managing the filling of a silo or storage system is essential in many sectors, from agriculture to industry. A level sensor enables precise monitoring of the quantity of liquid or solid product stored, whether in grain silos or silos for liquid products. The integration of this type of sensor facilitates remote monitoring and helps anticipate replenishments. Find out how to choose the right level sensor for your needs.

The filling of a silo or storage system needs to be precisely controlled, whatever the industry. Level sensors provide information on the quantity of material present – whether liquid or solid – and enable better planning of inventory management operations. Their use helps to anticipate replenishments and avoid overloads or stock-outs.

Why install a level sensor in your silos?

The challenges of level management in silos or other storage facilities (liquid or solid) are numerous. Accurate monitoring of level measurement in facilities is essential to avoid stock-outs or unnecessary surpluses, which can lead to additional costs and disruptions in the supply chain.

Reduce the risk of breakage or surplus

Without a reliable level sensor, it’s difficult to know exactly what’s in stock. Product shortages or surpluses generate unnecessary costs and inefficiencies. Precise monitoring of level measurement avoids these errors by providing data on filling, flow, pressure, etc.

Optimize logistics and procurement

Inventory optimization starts with accurate measurement of bulk solids levels. A connected sensor helps you better manage your liquids and powder materials by anticipating replenishment, thus reducing logistical errors and warehousing costs.

Gaining autonomy through connectivity

Silo level sensors provide the autonomy to remotely monitor installations and respond to regular alerts, whether for of liquids or solids. The system automatically alerts you when levels are too low or too high, enabling you to better manage your storage process by limiting human intervention.

Applications in agriculture, industry, construction…

Level sensors are used in a wide variety of sectors. For example, in agriculture, to monitor grain stocks, or in industry, to measure liquids in tanks or other types of container. These systems are also used in the construction industry to optimize the management of powdered materials or fluids in storage facilities. The application of these sensors in industry helps to improve productivity by optimizing control of liquid and solid levels.

Which level sensor should you choose for your silo?

The choice of level sensor depends on a number of criteria, such as the environment, the accuracy required, and the nature of the product to be measured. Different technologies are available: radar, ultrasonic and capacitive.

Radar, ultrasonic and capacitive sensors for precise level measurement

Here is a simple comparison table of the different types of level sensors:

| Sensor type | Operating principle | Benefits | Limits |

|---|---|---|---|

| Radar | Measurement based on electromagnetic waves. | Level accuracy in harsh environments (dust, humidity). | More expensive, requires open space. |

| Ultrasonic | Uses sound waves to measure distance. | Effective level measurement in controlled environments. | Less accurate in the presence of steam or dust. |

| Capacitive | Measures variation in electrical capacitance. | Ideal for bulk materials, reliable granular level measurement. | Sensitive to humidity and temperature. |

Compare technologies according to your needs

The choice of technology depends on your environment. For example, a radar sensor will be more suitable for a silo or container exposed to harsh outdoor conditions, while an ultrasonic sensor is perfect for more protected environments requiring fine precision in stock level measurement.

Selection criteria for level measurement of solids and liquids

To make the right choice, several criteria are essential:

- Container type: Determine whether you are measuring liquids or solids.

- Environment : External conditions such as temperature or pressure can influence sensor performance.

- Accuracy and maintenance: Sensors must offer reliable level accuracy while remaining easy to maintain.

Our advice for an optimal choice

Our connected solution for level measurement

We offer a range of level sensors for different types of storage systems, whether for bulk products or liquids. These sensors provide reliable measurements for efficient monitoring of silo levels.

Your IoT project from A to Z!

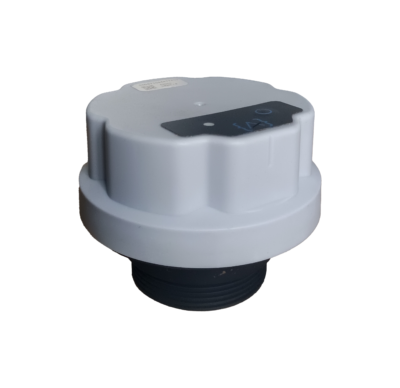

A robust, precise, self-contained sensor

Our sensors are designed to withstand the most demanding environments, from extreme temperatures to high pressure. They guarantee reliable liquid level measurement and long life, even in the harshest environments.

Data transmission for level monitoring

We use advanced communication technologies such as Sigfox, LoRa, and NB-IoT, enabling periodic transmission of solid and liquid material level data, with reduced energy consumption.

Easy integration into your industrial ecosystem

Our sensors are compatible with various existing systems, and installation does not require any major changes to your infrastructure. You can easily integrate the level measurement process into your industrial systems.

Monitoring and alerts from our IoT platform

Thanks to our IoT platform, you can periodically monitor liquid or product levels in your tanks, with customizable alerts for each user. The intuitive interface makes controlling and adjusting the parameters of your level measurement system simple and efficient.

Launch your connected tank project

with Four Data 🚀

Ready to optimize the management of your storage systems with a connected level sensor? Four Data offers solutions tailored to your specific needs, whether for liquids, solids or other materials.

Let’s discuss your needs

We would be delighted to discuss your projects and level measurement requirements. Make an appointment today to talk to an expert from our team.

A customized, scalable solution

With Four Data, you benefit from a flexible, scalable solution. We support you throughout the integration and optimization of your inventory management processes.