Fuel level monitoring: optimize your resource management

At a time when fuel prices fluctuates and actual consumption becomes a critical indicator, it is essential for professionals to check the fuel level in each tank. Whether it’s a vehiclea storage tankor an isolated site, an incorrect gauge reading or a lack ofreliable information can lead to breakdownsfailures delaysor even hidden costs costs.

Thanks to connected monitoring systemsit is now possible to take an accurate precise fuel level measurementautomate monitoring and detect any anomaly: leakage, theftor sensor failure. The aim of this article is to introduce you to the most frequent problemsproblems existing solutionsand concrete benefits of a remote monitoring product for fuel.

The challenges of fuel monitoring

Operating costs and uncontrolled losses

For a company managing a fleet of vehicles, fuel represents a significant proportion of the logistics budget. In some sectors, such as road haulage or agriculture, this item can climb even higher, having a direct impact on the profitability of operations.

Fuel losses come from several sources:

- Leaks due to wear and tear or tank failure

- Manual siphoning or automated theft during parking

- Over-consumption due to poor engine maintenance or inefficient driving

- Human errors in reading or entering measured levels

The absence of a reliable level monitoring system makes it difficult to detect these discrepancies. The result: expenses that go undetected, volumes consumed that are poorly accounted for, and inadequate control of fuel costs.

Resource security and theft prevention

The fuel theft is a well-known phenomenon in industrial, agricultural and construction environments. Methods range from the simple hose siphoning to direct handling of the level sensor. Most often, this happens on building sites, in isolated areas or in unguarded parking lots.

Conventional solutions, such as lockable plugs or manual inspections, are no longer sufficient. They are time-consuming, unreliable and, above all, reactive rather than preventive.

Conversely, a solution with an on-board sensor enables :

- A follow-up regularly of the level of each reservoir or tank

- From automatic alerts in the event of an abnormal drop or manipulation

- Data logging (historical readings) for proof or post-incident analysis

- Position tracking for equipment with GPS trackers

These measures help to protect resourcesbut also empower drivers and and operators in the field.

Environmental pressure and regulations

In addition to the economic aspects, poor fuel management fuel poses a environmental problem. Undetected leaks, overconsumption due to engine faults or overfilling can lead to serious damage. unnecessary CO₂ emissions and risks of soil pollution (particularly in the event of tank overflow).

In addition, certain regulations encourage (or require) companies to measure and reduce their carbon footprint. This is particularly the case in industrial sectors subject to standards such as :

- ISO 14001 environmental management

- SEQE-EU (European system of carbon quotas)

- Local tax incentives for energy monitoring technologies

By automating precise measurement of fuel volumecompanies can not only limit lossesbut also enhance their environmental commitment.

How does a fuel monitoring system work?

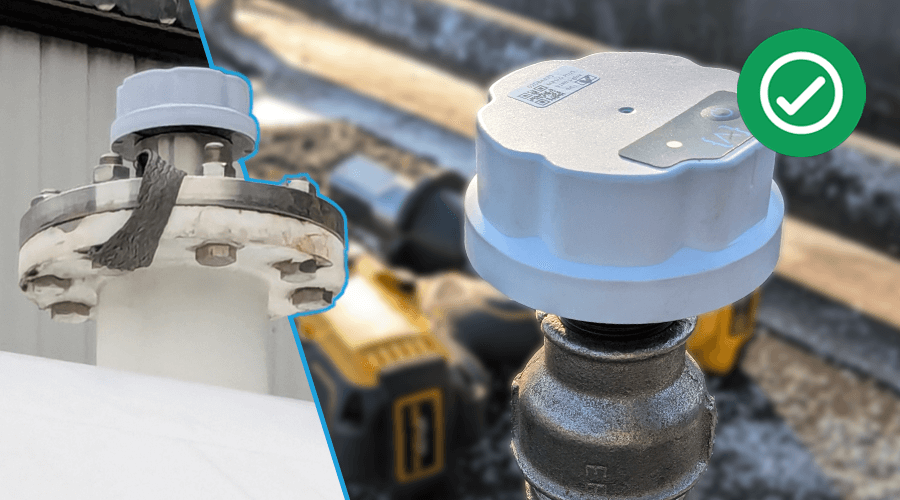

Measurement sensors (ultrasonic, pressure, gauge, CAN bus)

An efficient fuel fuel level monitoring system depends above all on the choice of sensor adapted. Each technology has its own advantages in terms of precisionand costand volume and installation conditionsinstallation.

| Technology | Measuring principle | Accuracy | Installation | Cost |

|---|---|---|---|---|

| Ultrasound | Sound wave reflected by the liquid | Correct | Out of contact (at top of tank) | Moderate |

| Pressure | Difference in fluid pressure | Very good | Fixed to tank bottom | High |

| Radar | Radar wave reflected by liquid surface | Very good | Non-contact (top of tank), often in ATEX zones | High |

| Ratiometric gauge | Voltage variation proportional to the level measured (often based on a variable resistor linked to a float) | Very good | Attaches directly to / replaces existing Rochester-type dial | High |

| Analog gauge | Float connected to a graduated rod | Variable | Integrated into equipment | Low |

| Capacitive probe | Electrical capacitance changes with liquid level | Good to very good | Liquid immersion | Moderate to High |

| CAN bus | Data retrieved via vehicle electronics | Very high | No physical modification | Low to moderate |

Every level sensor is selected according to the type of reservoirthe type of fuel (diesel, gasoline, water) and use (mobile or stationary).

Data transmission (Sigfox, NB-IoT, LTE-M…)

Once the data has been measured, it must be transmitted to the monitoring platform. This is done via low-speed IoT networksnetworks, chosen according to location, network network coverage and energy consumption consumption.

| IoT network | Range | Sensor autonomy | Communication cost | Coverage France |

|---|---|---|---|---|

| Sigfox/LoRa (LPWAN) | Very long (rural) | 3 to 7 years | Very low | Correct |

| NB-IoT | Medium to long | 2 to 5 years | Low | Very good |

| LTE-M | Medium | 1 to 3 years | Moderate | Very good |

The choice of network has a impact on system reliabilityparticularly in isolated areas or dense industrial environments.

An up-to-date coverage map of IoT operators is recommended to validate the most suitable technology for your installation site.

✅ Good to know : Four Data provides a free tool to test network coverage (LoRa, Sigfox, LPWAN) directly on your operating site.

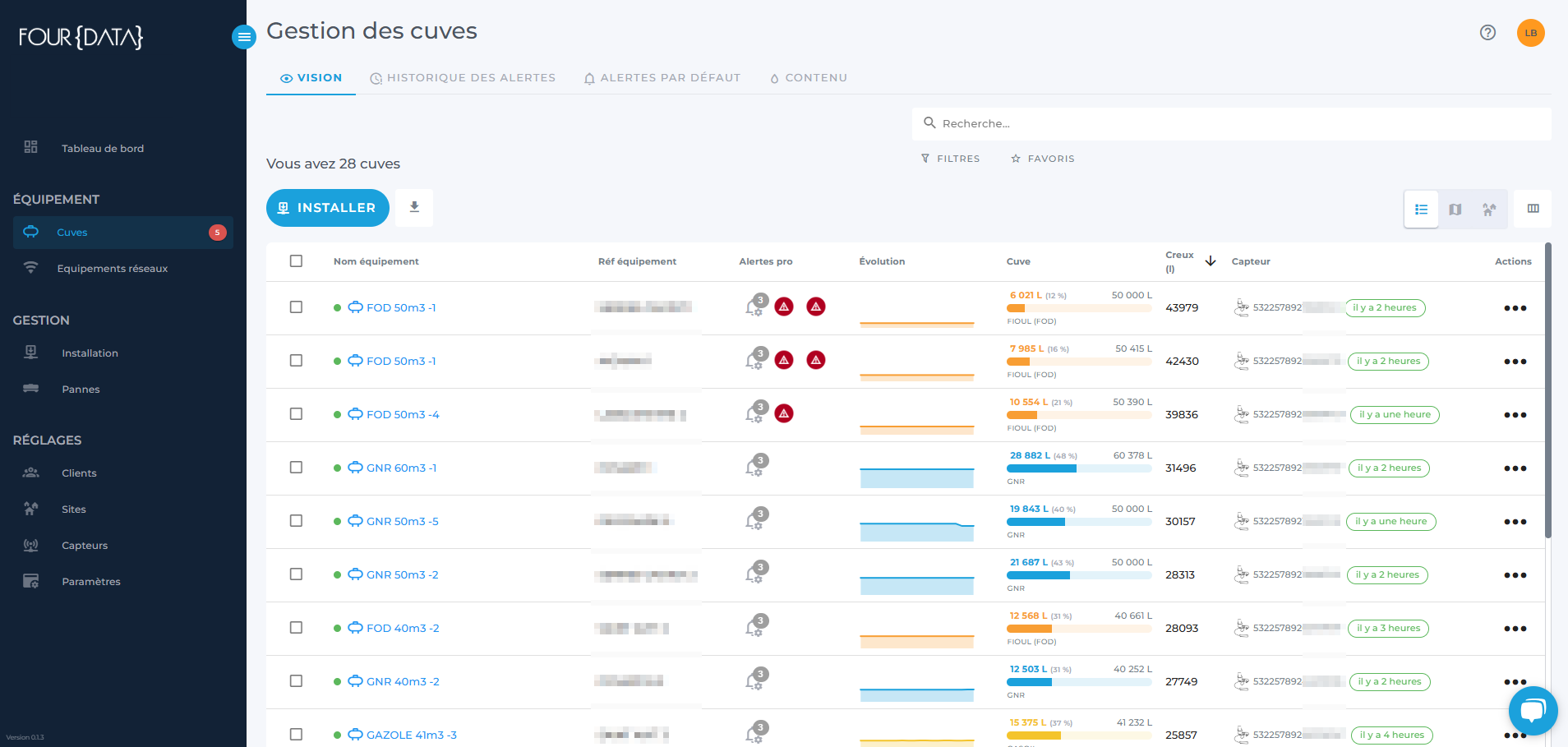

Control interface and real-time alerts

All the data transmitted is centralized in a software interface accessible remotely. This tool is the heart of the system management.

Key features include:

- Visualization of level of each tank or reservoir

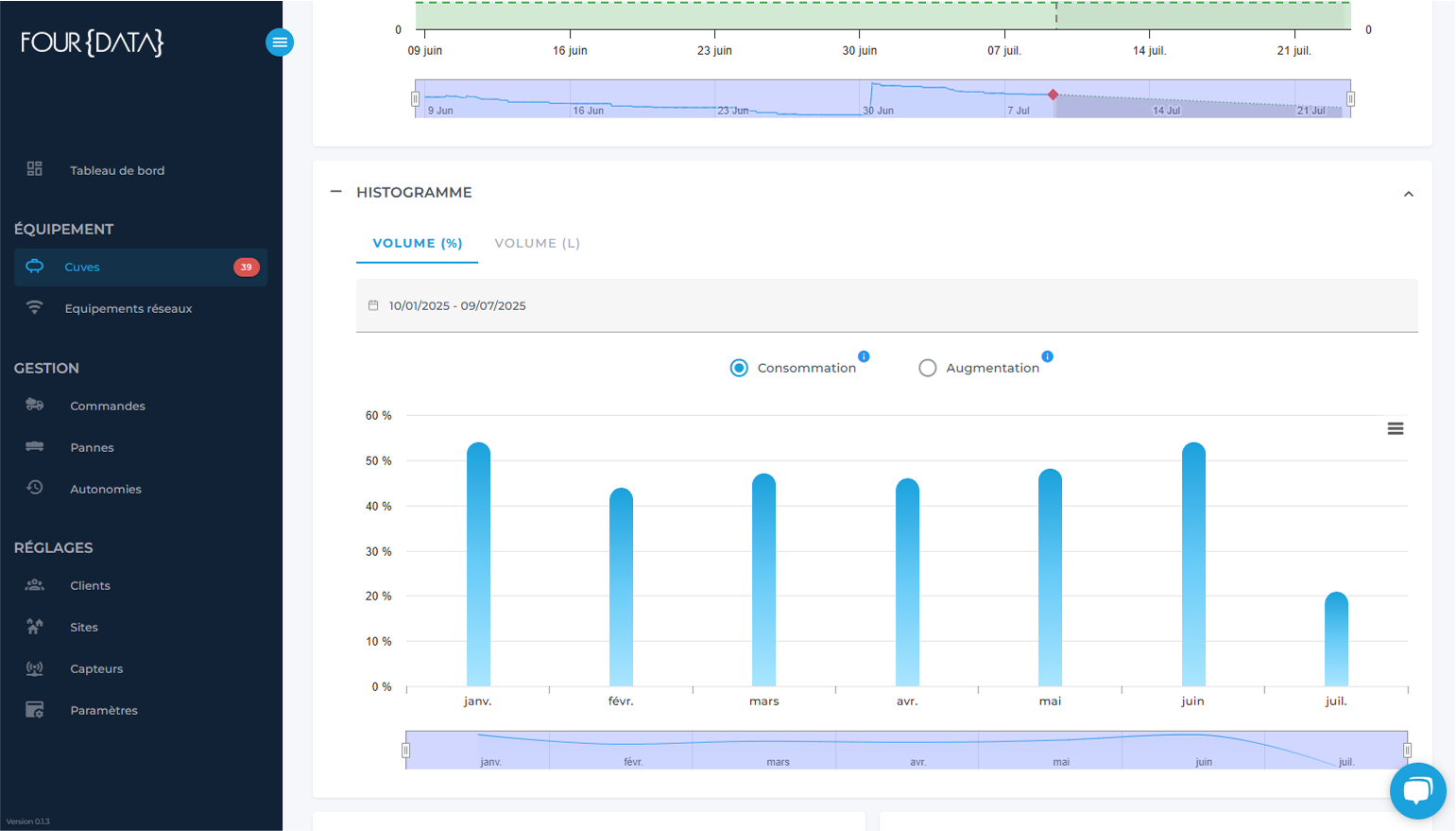

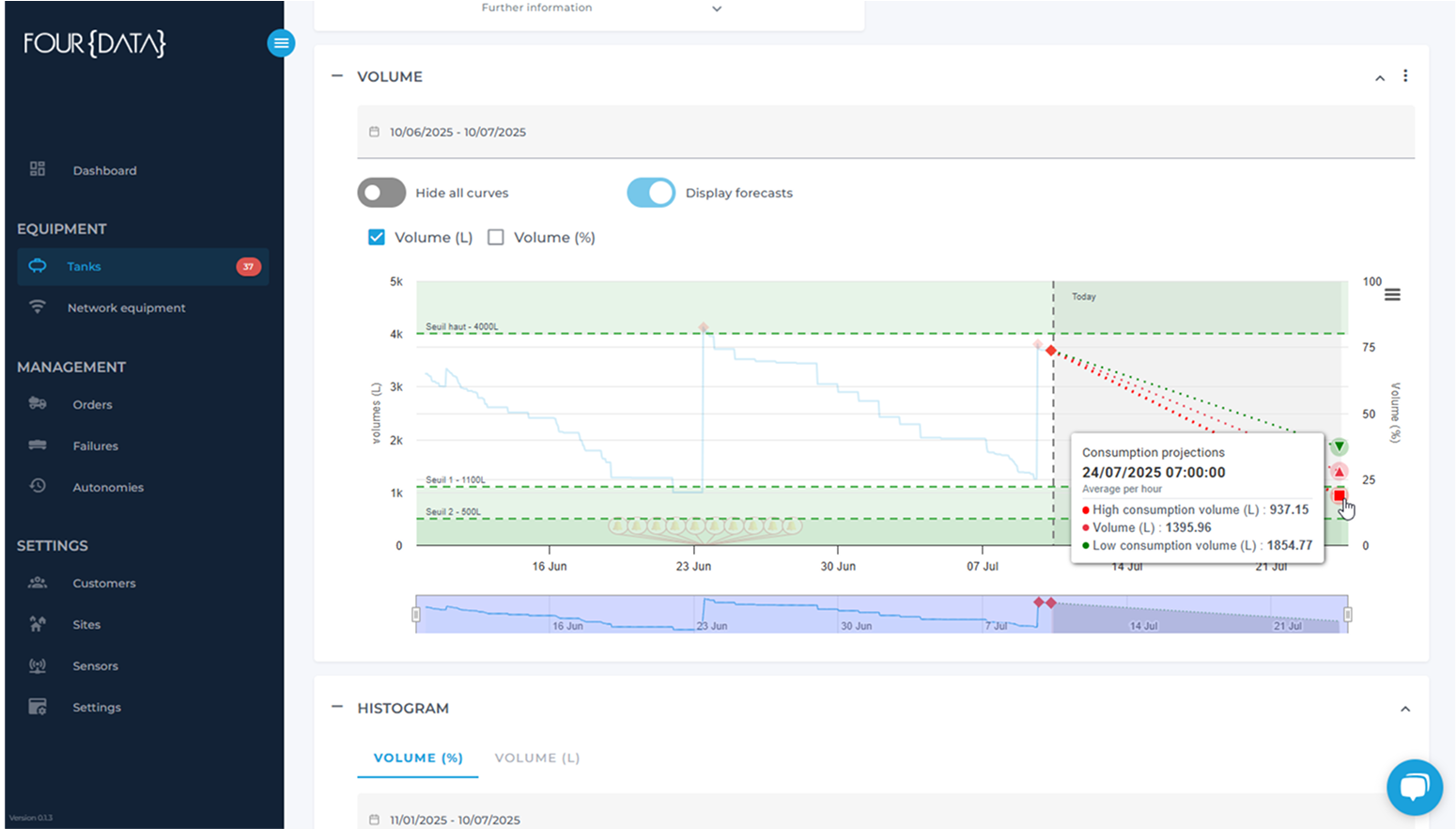

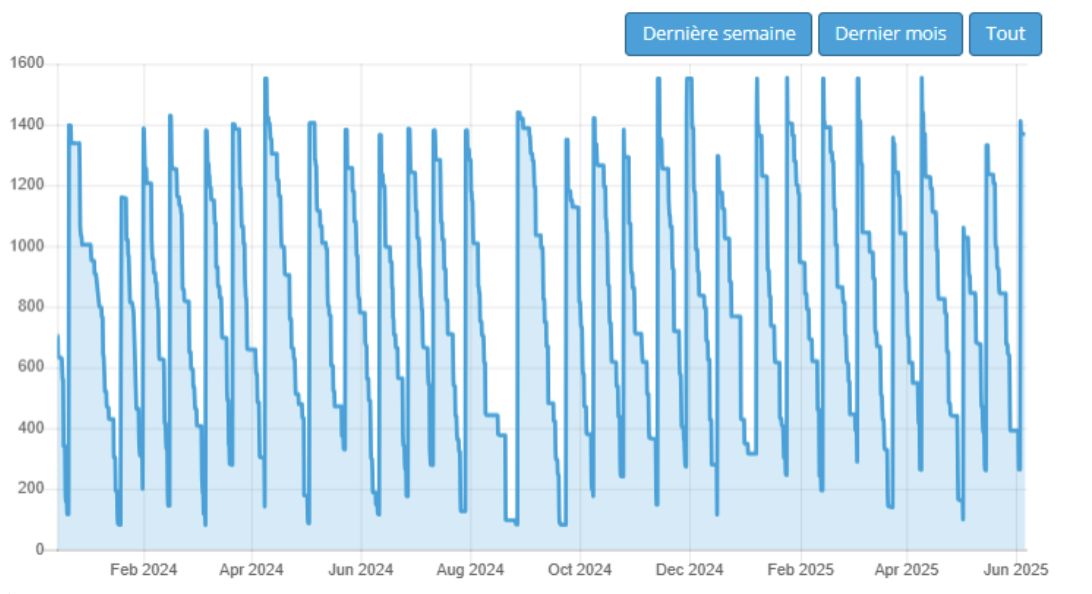

- Measurement historytrend curves, multi-site comparison

- Automated alerts in the event of a rapid drop or critical threshold

- Download activity or or anomaly reports

- Links with other connected equipment or business software

Example: a logistics manager can receive an SMS alert when a tank falls below 15% volume, enabling an immediate immediate reaction.

What benefits can you expect from a remote fuel monitoring solution?

Cost reduction and procurement optimization

Install a remote fuel level fuel level monitoring system enables immediate rationalization supplies. With reliable, real-time dataLogistics managers can avoid :

- Unnecessary deliveries (tanks still full)

- Supply disruptions

- More costly emergency interventions

Typical customer feedback shows savings of between 10% and 20%. on the fuel budget from the very first year. These gains can be explained by better filling planning and a reduce wasted volumes.

Example of a monitored tank, here we can see that replenishments are made when the tank is at a low level (between 400 and 200 l remaining) – no replenishment errors when the tank is at a high level.

Automated fleet tracking

Thanks to the integration of an automated automated monitoring systemmany previously manual tasks are now handled by the solution:

- Automatic generation of consumption reports

- Detection and notification of critical levels

- Replenishment forecasts based on historical data

- Multi-site monitoring from a single point of entry

This frees up operator time and eliminates the human errors associated with manual readings. manual readings or approximate entries.

📈 Suggested simplified workflow :

- Sensor detects low level

- The alert is sent automatically

- The software proposes an optimized filling date

- The driver is informed via the mobile application

Transparent reporting and decision support

Have a clear dashboard has become essential for resource management. A good remote fuel monitoring tool offers views adapted to different profiles:

- Supervisors : overview of remaining volumes

- Finance : vision by site, with aggregation of volumes consumed by liquid type

- Technical : history of sensor failures and anomalies

Example of a dashboard :

- Current levels per tank

- Daily consumption history

- Alerts triggered during the month

- Performance comparison by vehicle or machine

Our use cases at Four Data

Oil depots and industrial tanks

In industrial environments, accurate fuel level management is crucial to ensure continuity of operations and avoid costly interruptions. Our monitoring solutions enable real-time measurement of the volume of fuel in tanks, facilitating supply planning and rapid detection of anomalies.

In oil depots, for example, the integration of connected level sensors has reduced losses due to leaks and overfilling, while optimizing refueling rounds.

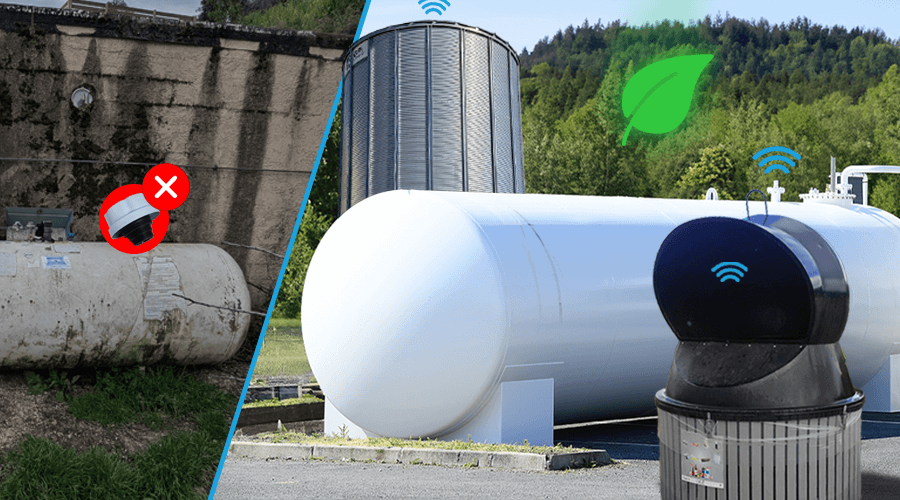

Agricultural tanks and fuel management on isolated sites

In the agricultural sector, farms are often located in rural areas with limited connectivity. Our fuel level monitoring solutions are designed to operate autonomously, with low power consumption, ensuring reliability even in the most remote areas.

What our customers say : Chimirec, Avril, Tibbloc…

Chimirec Dargelos

“Chim’Sonde is a differentiating offer for Chimirec. It is part of the three-pronged approach that our customers undertake on a daily basis: environmental impact by preventing tank overflows, digitalization by simplifying the management of this waste, and traceability enabling customers to track and record their liquid waste production on a daily basis.”

– Aurélien DUMARCHE, Sales Director

Avril Group

“Oleo100 and more generally the Avril Group are keen to move forward with the deployment of IoT solutions with a real objective of improving customer service.”

– Geoffroy Pertuisot, IT Department

Tibbloc

“The Four Data solution has given us great responsiveness. The partnership with Four Data has enabled us to be very responsive to our customers, whether in terms of repairs or fuel supply.”

– Bruno LEMOINE, Hotline and after-sales service manager

Which technical solution for your project?

Selecting sensors for specific applications

The right sensor is not the one that offers the highest absolute accuracy, but the one that is adapted to your environment and your constraints: type of tank, type of fluid (fuel, water), accessibility, available power supply.

| Tank type | Estimated volume | Recommended sensor | Key benefits |

|---|---|---|---|

| Fixed above-ground tank (diesel) | > 10 000 L | Ultrasonic / pressure sensor | Ultrasonic: no direct contact, ideal for outdoor use

Pressure: immersed measurement, good accuracy even on large volumes |

| Underground or closed tank | 2 000 – 10 000 L | Pressure sensor | Reliable, watertight installation for environments at risk of humidity or flooding |

| Small mobile tank (vehicle) | < 500 L | CAN bus | No drilling, native reading via motor |

| Agricultural or isolated reservoirs | Variable | Low-power ultrasonic or pressure sensor | Long autonomy, optimized transmission |

Integration with your existing systems

The Four Data solution is designed to integrate easily into your existing business tools, thanks to :

- A API for data transmission (level, alert, volume consumed)

- Compatibility with ERP solutions ( iCopitole and PTV group ) info : Four Data general presentation .pdf

- Secure connection mode (HTTPS, authentication token)

This enables intelligent data centralizationwithout changing your internal processes.

Customized, scalable IoT platform

Four Data offers a fully modular supervision platformbuilt to grow with your project:

| Available modules | Main function |

|---|---|

| Level visualization | Regular view, history, graphs |

| Intelligent alerts | Customized thresholds, direct notification |

| Automated reporting | PDF exports, weekly/monthly reports |

| Geolocation (optional) | Location of tanks and vehicles |

| Supply forecast | Estimate based on actual consumption |

| Customized dashboard | BI view by user role |

✅ Checklist – Your project, step by step :

- Evaluating uses

- Choosing the right sensors

- Setting critical thresholds

- Integrate into your environment

- Measure, adjust, evaluate

Why choose Four Data?

Complete mastery of IoT, from sensor to cloud

At Four Data, we’re not just integrators. We are designers, manufacturers and developers of our own solutions. This means that we master each and every link in the IoT value chainvalue chainembedded electronics to data restitution.

Our teams are organized around two complementary divisions:

- Hard & Network sensor design, prototyping, small series production, network management (Sigfox, LoRa, LTE-M…)

- Soft & Data: application development, data processing, security, APIs, BI and personalized visualization

Customized support, from POC to industrialization

We don’t just deliver a product. Each customer project follows a structured approachbased on listening, agility and feedback:

- Understanding needs Analysis of site conditions, constraints and uses

- POC (Proof of Concept) installation of a pilot system on site

- Data validation Data validation: comparison of results with day-to-day business

- Full-scale deployment customized configuration, field support

- Monitoring & evolution Reports, maintenance, proactive support

🧪 Examples of POC :

- Monitoring fuel oil tanks on an isolated logistics site

- Fuel tracking for a municipal bus fleet with interconnected platform

- Automated control of fast-moving agricultural tanks on a CUMA farm

A results-oriented approach, with BI and intelligent alerts

Our platform does more than simply provide information. It offers powerful decision-making toolsaccessible to all levels of the organization.

Key benefits :

- Customizable indicators Customized indicators: remaining volumes, filling frequency, average consumption per vehicle or equipment

- Conditional alerts according to thresholds, time slots, geolocation

- Automated exports Exports: to Excel, PDF, or via API to your in-house tools

- BI modules: cross-reference fuel data with weather, planning or business data

FAQs

Ready for action?

Contact us for your intelligent fuel management project

Whether you’re a fleet manager, logistics manager or farmer, we have the right fuel monitoring solution tailored to your needs.

Take advantage of our expertise in sensors, connectivity and data to transform your supplies into performance drivers.

👉 Make an appointment with a Four Data expert A consultant will get back to you within 24 hours to launch your project.

You may also be interested in these articles :