Connected gauge for industrial lubricants – The IoT solution to never run out of oil

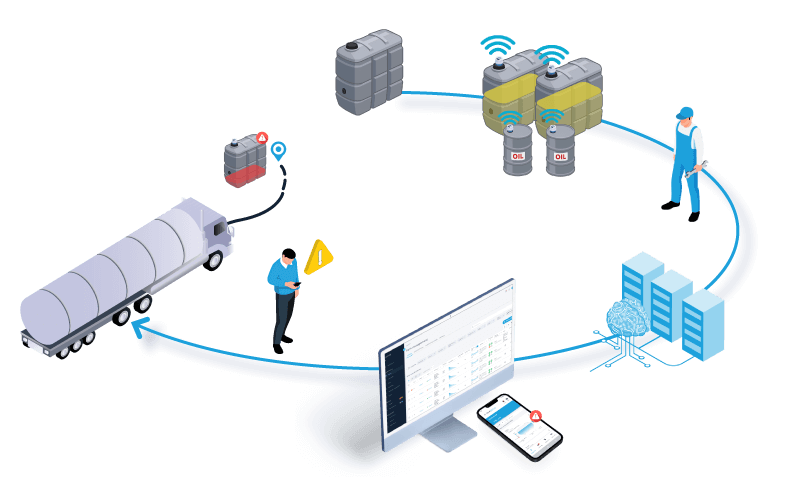

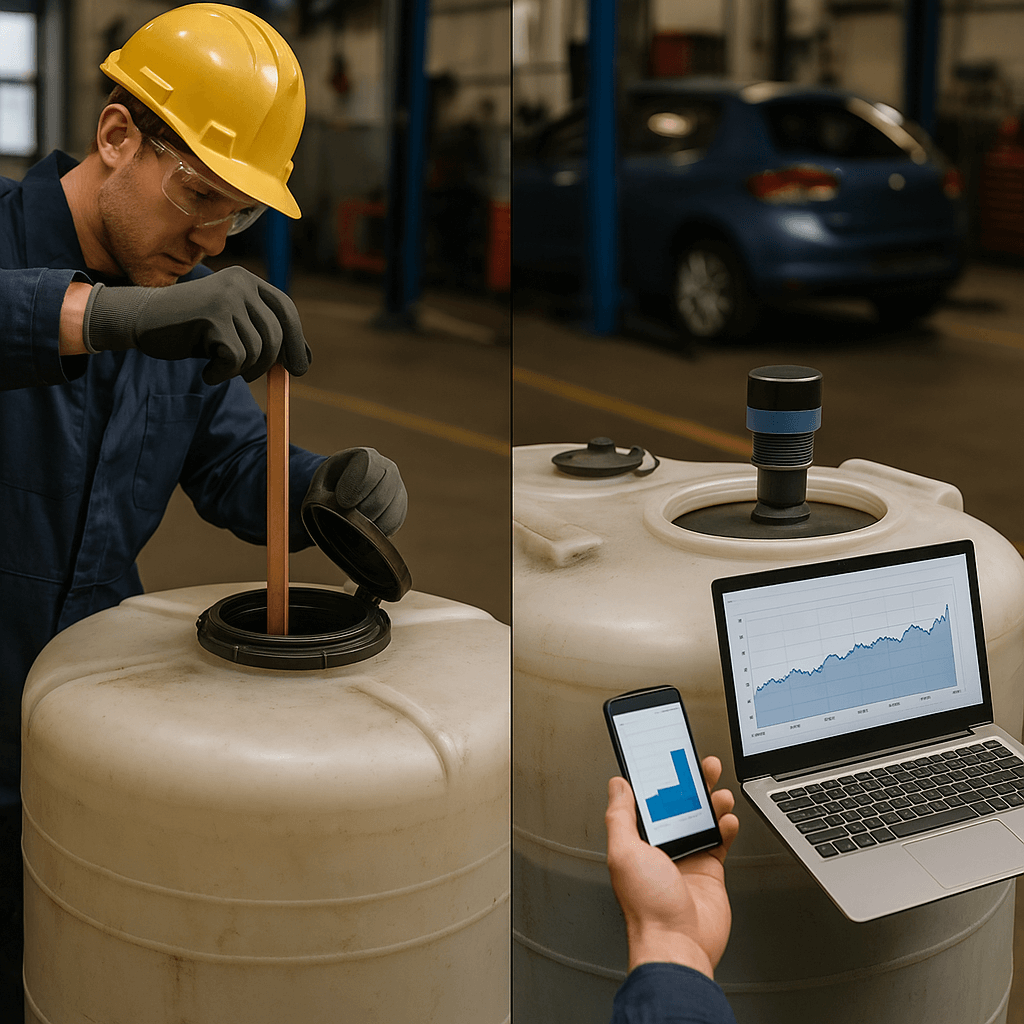

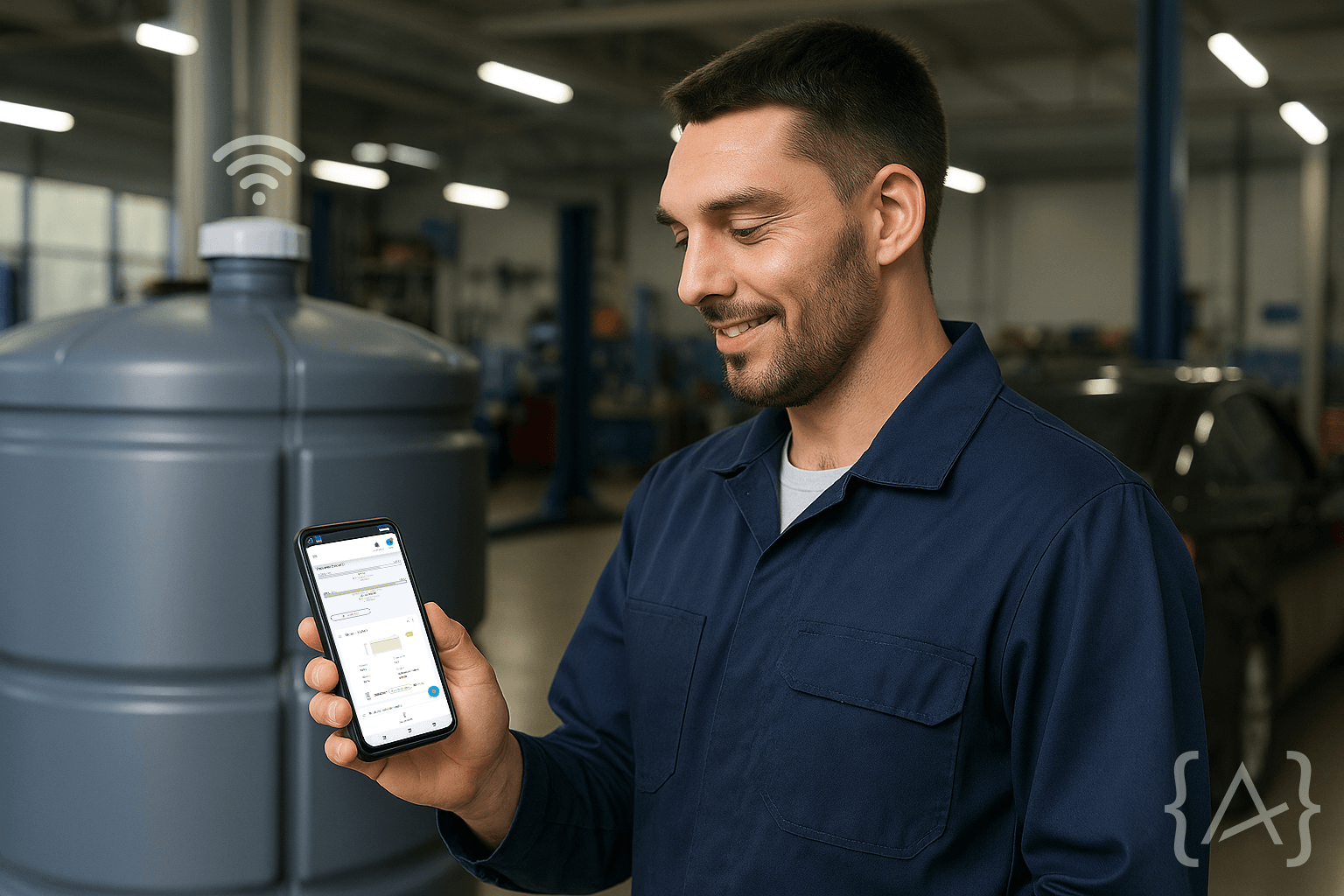

Manage your industrial lubricants with reliability and peace of mind thanks to our connected gauge. Our solution enables you to remotely monitor your tank levelsprevent any stock-outs and optimize your supplies. By connecting your tankers, you gain in reactivityin productivity and visibility over your volumes of liquid available. L’ IoT applied to lubricant management becomes a strategic lever for your operations.

TABLE OF CONTENTS

Why equip your lubricant tanks with a connected gauge?

Industrial challenges: stock shortages, costs, safety

Given the realities of the industry, monitoring lubricant volumes lubricants, d’oils or industrial liquids in tanks is a critical factor in production continuity. Here are the main issues addressed by a connected gauge:

–Lubricant failure: an empty tank can bring a production line, or even an entire plant, to a standstill. The cost of an unplanned shutdown can run into thousands of euros a day.

–Logistical and organizational costs: imprecise inventory management leads to emergency deliveries or unnecessary rounds, impacting profitability.

–Environmental risks: a tank overflow or spill can cause pollution that is costly for the manufacturer to manage.

–Lack of multi-site visibility: managers often have to supervise several sites remotely, without centralized feedback.

–Regulatory compliance: some industries require proof of tracking and consumption, which is difficult to trace using manual methods.

A connected gauge can meet all these challenges with simple, automated, centralized control.

➡️ The switch to a connected gauge is not simply a technical upgrade, it’s a structural structural improvement of industrial operations.

Limits of conventional solutions: manual readings, errors, inaccuracies

Comparison – Manual gauging vs. connected gauging

| Criteria | Manual gauge | Four Data connected gauge |

|---|---|---|

| Method | Visual reading or measurement with graduated rod | Digital sensor + remote transmission |

| Reading frequency | Irregular / according to human availability | Continuous, configurable (e.g. every 6 h) |

| Data reliability | Medium: operator-dependent | High: automated, traceable measurements |

| Reactivity | Low: late detection of risks | Immediate: alerts when critical thresholds are reached |

| Hidden costs | Time spent, errors, unnecessary interventions | Optimization of stocks, reduction in travel |

| Remote access | No | Yes, via multi-media connected platform |

Gauges for lubricant monitoring

To ensure reliable, continuous lubricant monitoring, Four Data offers three connected sensors adapted to each type of tank and industrial use:

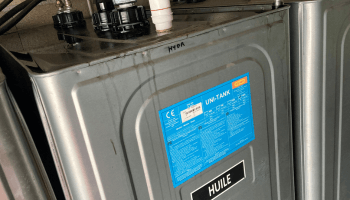

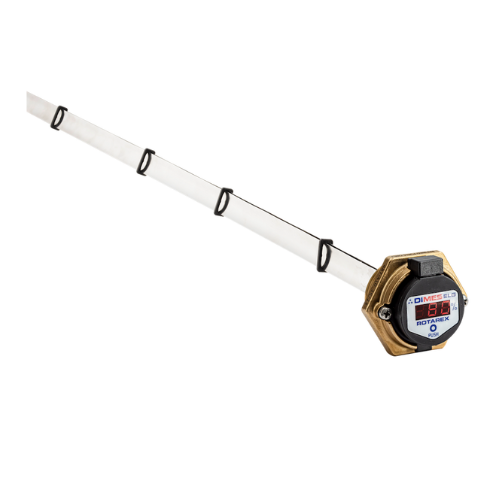

Ultrasonic gauge: ideal for plastic or metal tanks, it measures level using acoustic waves without direct contact with the liquid. A robust and versatile solution, it guarantees accurate readings even in difficult environments.

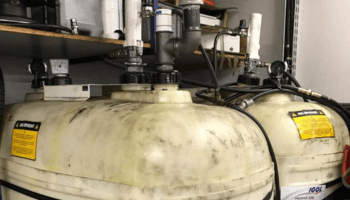

Pressure gauge: designed for large-capacity or buried tanks, it calculates level by the pressure exerted by the liquid column. This simple, efficient technology is perfectly suited to sites where compactness and reliability are essential.

Capacitive probe: optimized for lubricant drums and containers, it provides fine measurement thanks to variations in the electric field. Its accuracy and reliability make it a benchmark solution for replacing traditional mechanical gauges.

What are the benefits for your business?

Reduce production downtime and anticipate needs

Imagine a production line at a standstill due to an unexpectedly empty lubricant tank. This type of incident, which is still common in industrial environments, not only leads to costly immediate economic lossesbut also weakens the entire downstream logistics chain.

Thanks to our connected gauge, this scenario is avoided.

This ability to anticipate real needs not only helps to protect production facilitiesbut alsoalleviate the pressure on maintenance teams who are often called upon in a hurry.

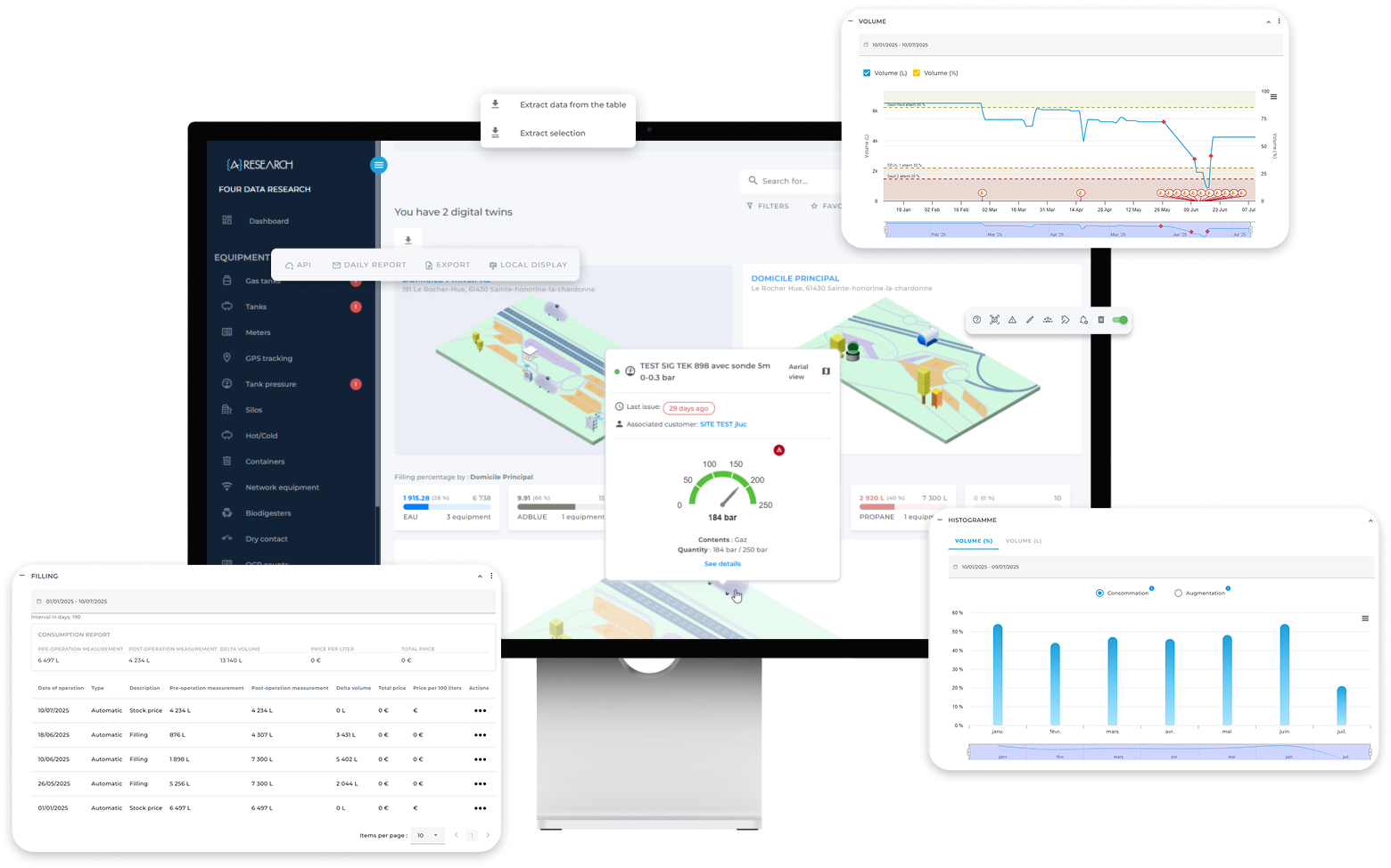

Data-driven management: reporting, dashboards, ROI

Our platform enables you to make decisions based on concrete dataand no longer on estimates or irregular readings.

📈 One-click indicators :

- Real-time fill rate

- Consumption history by site / lubricant type

- Alerts triggered by period

- Volumes delivered vs. consumed

- Supply forecasts

💰 Examples of impact on ROI :

- -25% fewer emergency logistical interventions

- -15% less lubricant loss due to dosing errors

- +20% time saving for maintenance and procurement teams

These figures vary according to the operating context, but the results are systematically measurable from the very first months following deployment.

Logistics optimization: deliveries, routes, inventory

With lubricant volumes often dispersed between several sites, knowing what to deliver, when and where becomes a logistical challenge. Our solution acts as a logistics information hubin direct contact with your teams or service providers.

➡️ Result : fewer trips, fewer errorsand better management of transport resources.

Customer case study: optimizing lubricant management

Initial objectives and background

Lubexcelan independent distributor of industrial lubricants and motor oils, wanted to increase control over volumes for its B2B customers, while optimizing its own logistics flows. The constraints were clear: several distant sites, tanks of various sizes (steel and plastic), and a growing need for reliability to avoid critical stock-outs. Their objective: offer a differentiating connected service value-added service.

1.technicaldeployment and configuration

Course of the project :

- Initial audit of customer sites (type of tanks, volume, accessibility)

- Choice of suitable sensors :

- Capacitive gauge for metal drums

- Ultrasonic gauge for plastic tanks

- On-site installation with standard adapters (1”1/2 and 2”)

- Connection to the private LoRa network provided by Lubexcel

- Platform configuration Four Data with alert thresholds, user roles and ERP synchronization

- Test period (POC) over 4 weeks with weekly follow-up

- Widespread deployment at 5 strategic customer sites

2.results: logistics, costs, reliability

Planning time4h/week30 min/week

| Indicator | Before deployment | After 3 months with Four Data |

|---|---|---|

| Emergency deliveries/month | 6 | 1 |

| Lubricant breakage rate | 12 % | 0 % |

| End customer satisfaction | Average | High |

“The Four Data platform has enabled us to provide a concrete additional service to our customers service to our customers streamlining our own routes. Our sales people now have a clear view of customer needs and alerts at the right times.”

– Aurélien R., Lubexcel Marketing Manager

Why choose Four Data?

A modular, agnostic IoT platform

Each industrial site has its own specificities: type of tanks, nature of oils or lubricants, environmental constraints, available network… That’s why our solution is designed to be modular, scalable and agnostic.

💡 What this means in concrete terms :

- Modular You activate only the services you need (tracking, alerts, multi-site, API, etc.).

- Scalable possibility of adding new sensors or volumes without technical redesign

- Agnostic compatible with all brands of sensors, all network technologies, and can be integrated into your information system

“Four Data enabled us to adapt the solution to our internal constraints, without disrupting our existing process.”

– Maintenance Manager, industrial fluids manufacturer

Compatible networks: Sigfox, LoRa, NB-IoT, LTE-M

We offer several communication networks to connect your sensors, depending on the field configuration (wall thickness, distance, power supply, etc.).

| Network | Typical range | Power consumption | Ideal use |

|---|---|---|---|

| Sigfox | Up to 10 km | Very low | Rural areas, isolated tanks |

| LoRa | 2 to 15 km | Low | Industrial sites with dedicated infrastructure |

| NB-IoT | 1 to 10 km | Medium | Urban buildings, moderate depth |

| LTE-M | 1 to 5 km | Medium to high | Dynamic sites, mobile sensors |

Project methodology: from analysis to deployment

We don’t just provide you with a connected gauge. We co-constructing a sustainable project tailored to your organization. Here’s our proven approach:

- 🔍 Understanding – Analysis of your uses, constraints and objectives

- 💡 Ideation – Technical proposal and definition of functional scope

- 🧪 POC (Proof of Concept) – Field test on a pilot site to validate the solution

- 🚀 Deployment – Industrialization on one or more sites

- 🤝 Follow-up – Technical support, functional upgrades, long-term support

🛠️ “What made the difference was Four Data’s regular follow-up. The project team remained available every step of the way.”

Customer satisfaction: +60,000 connected objects

With over 60,000 connected objects deployed to date, Four Data is a key player in the connected management of industrial fluids and volumes.

📌 What this translates to :

- A mature tried and tested in demanding environments

- Customers in a wide range of sectors: boiler making, lubricants, plastics, agro-industry, etc.

- A satisfaction rate of over 95%according to our latest customer surveys

“Thanks to Four Data, we’ve eliminated logistical emergencies and anticipated our needs. There’s no going back now.”

– Logistics manager, industrial oil distributor