Connected tank – Monitor your levels in real time

The connected tank transforms the way you manage your stocks of fuel, water or chemicals. Thanks to an intelligent gauge equipped with a high-precision sensor, you have real-time access to the exact level of your liquids. No more time-consuming manual checks: data is automatically transmitted via a secure IoT network (Sigfox, LoRa, NB-IoT, LTE-M). Alerts, customized thresholds and an intuitive interface guarantee optimized management, controlled consumption and scheduled deliveries at the right time.

What is a connected tank?

Definition and operating principle

A connected tank is a reservoir equipped with a smart gauge and a high-precision sensor (ultrasonic, pressure or radar) that continuously measures the liquid level (fuel, water, oil, chemicals). The data is automatically transmitted via a IoT network networks (Sigfox, LoRa, NB-IoT, LTE-M) to a software platform.

On this interface, the client can consult its information at any time: remaining volume, daily consumption, thresholds reached. In the event of an anomaly or specific requirement, a alert is triggered automatically (SMS, e-mail, notification).

The limits of traditional tanks

- Time-consuming, error-prone manual measurement.

- High risk of rupture or overstock due to lack of accurate tracking.

- No automatic alerts → need to physically check each tank.

- Dispersed management: no centralized data or multi-site vision.

Why adopt a connected tank?

Adopting a connected tank means transforming management into a reliable, automated and secure process:

👉 Time-saving No more manual readings – everything is just a few clicks away.

👉 Information reliability Data is continuously updated, with no risk of human error.

👉 Peace of mind thanks to automatic alerts and configurable thresholds, you can anticipate needs and plan your deliveries without stress.

How does a connected tank work?

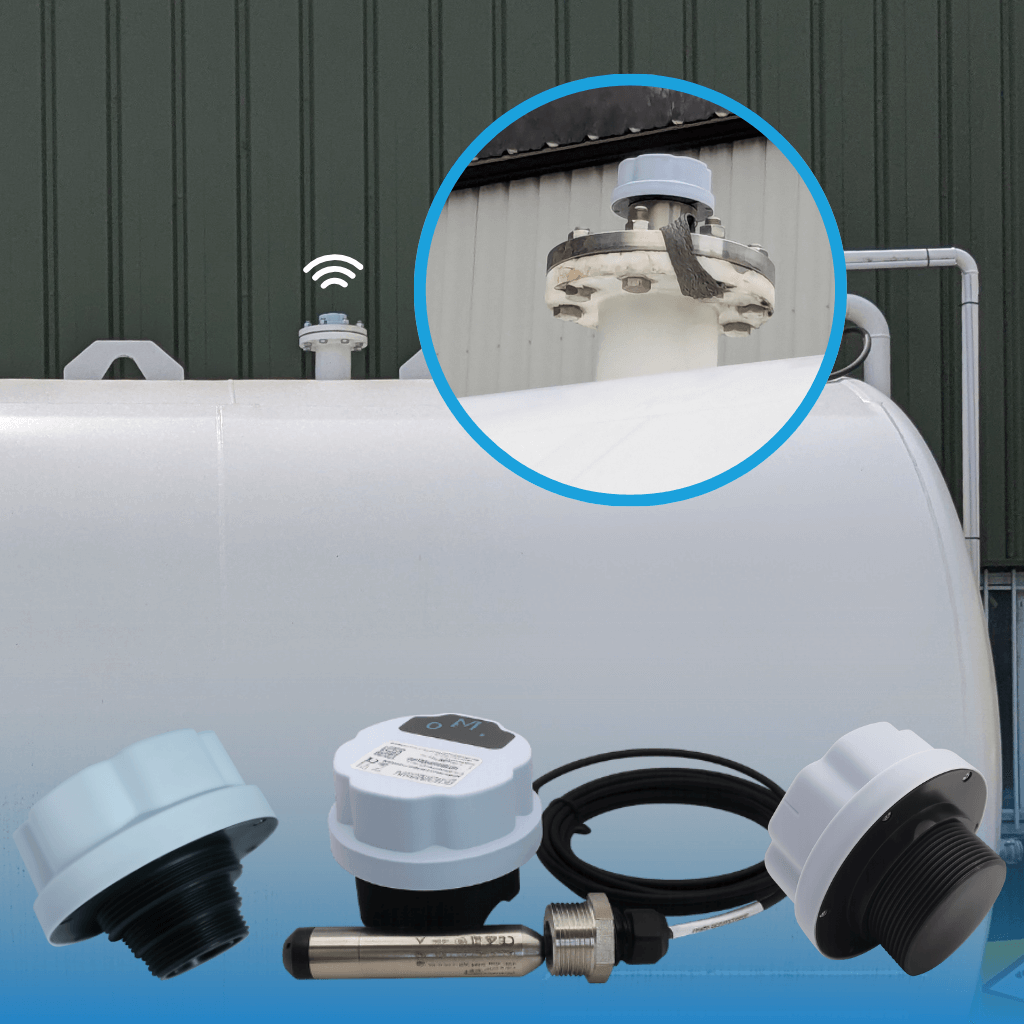

Intelligent sensors (ultrasound, pressure, radar, etc.)

Each connected tank is equipped with a intelligent probe adapted to the type of liquid to be monitored:

| Sensor type | Preferred use | Advantages | Limitations |

|---|---|---|---|

| Ultrasonic | Fuel, water, standard products | Non-contact measurement, reliable outdoors | Sensitive to foam or deposits |

| Pressure | Oil, dense liquids | High precision, suitable for underground tanks | Requires periodic maintenance |

| Radar | Chemicals, hydrocarbons | Very high accuracy, insensitive to temperature | higher cost |

👉 The choice of sensor depends on the customer requirements nature of the liquid, environment (outdoor/indoor) and accuracy required.

Data transmission via IoT (Sigfox, LoRa, NB-IoT, LTE-M)

Once the measurement has been taken, the sensor transmits the level data to the platform via a secure IoT network:

- Sigfox / LoRa ideal for rural areas and isolated sites, thanks to their low energy consumption.

- NB-IoT / LTE-M ideal for urban and industrial environments, with higher throughput and 4G/5G coverage.

Coming soon: satellite connection

This flexibility guarantees continuous operation even in white zones. Visit battery for many years of maintenance-free operation.

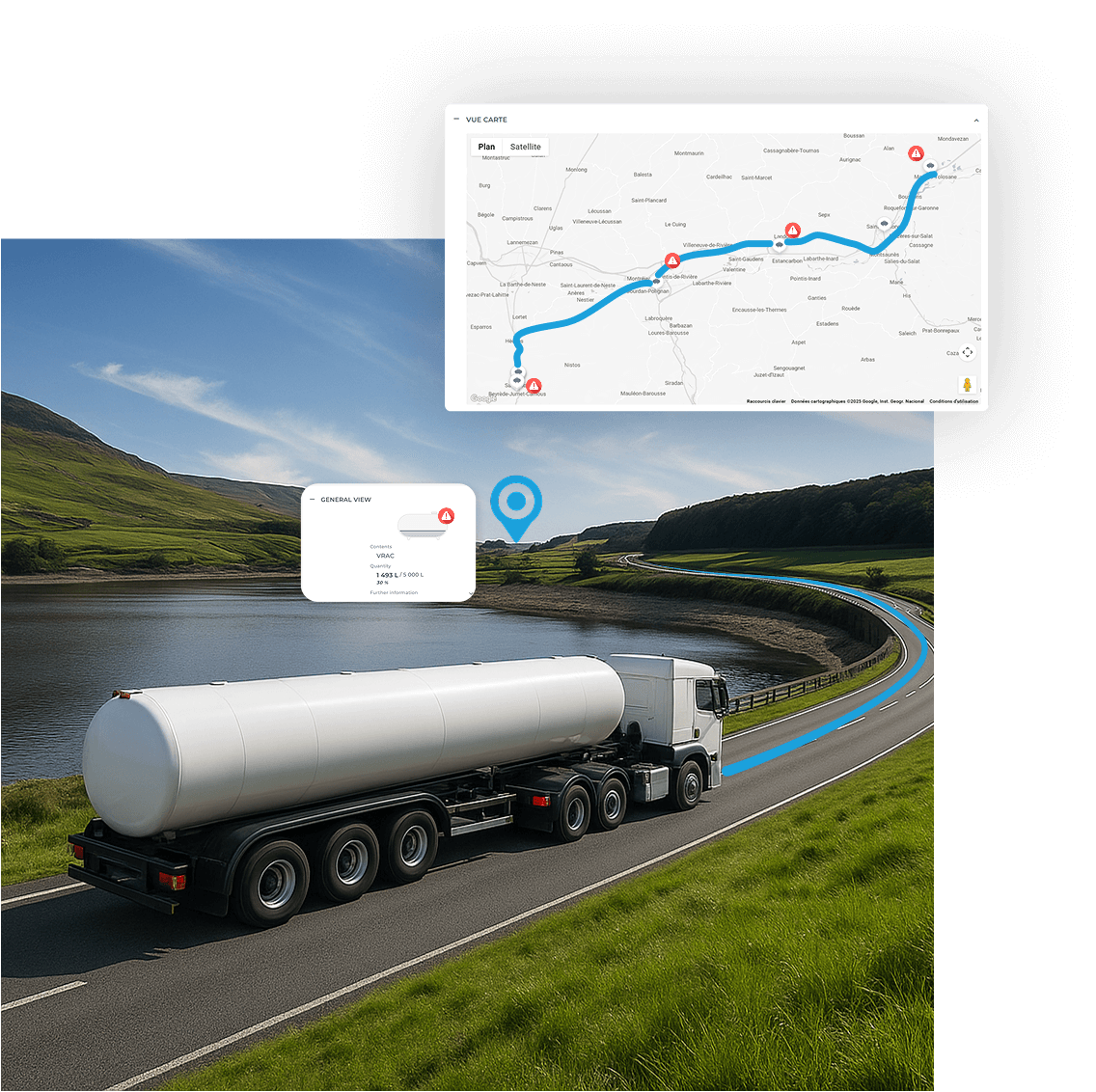

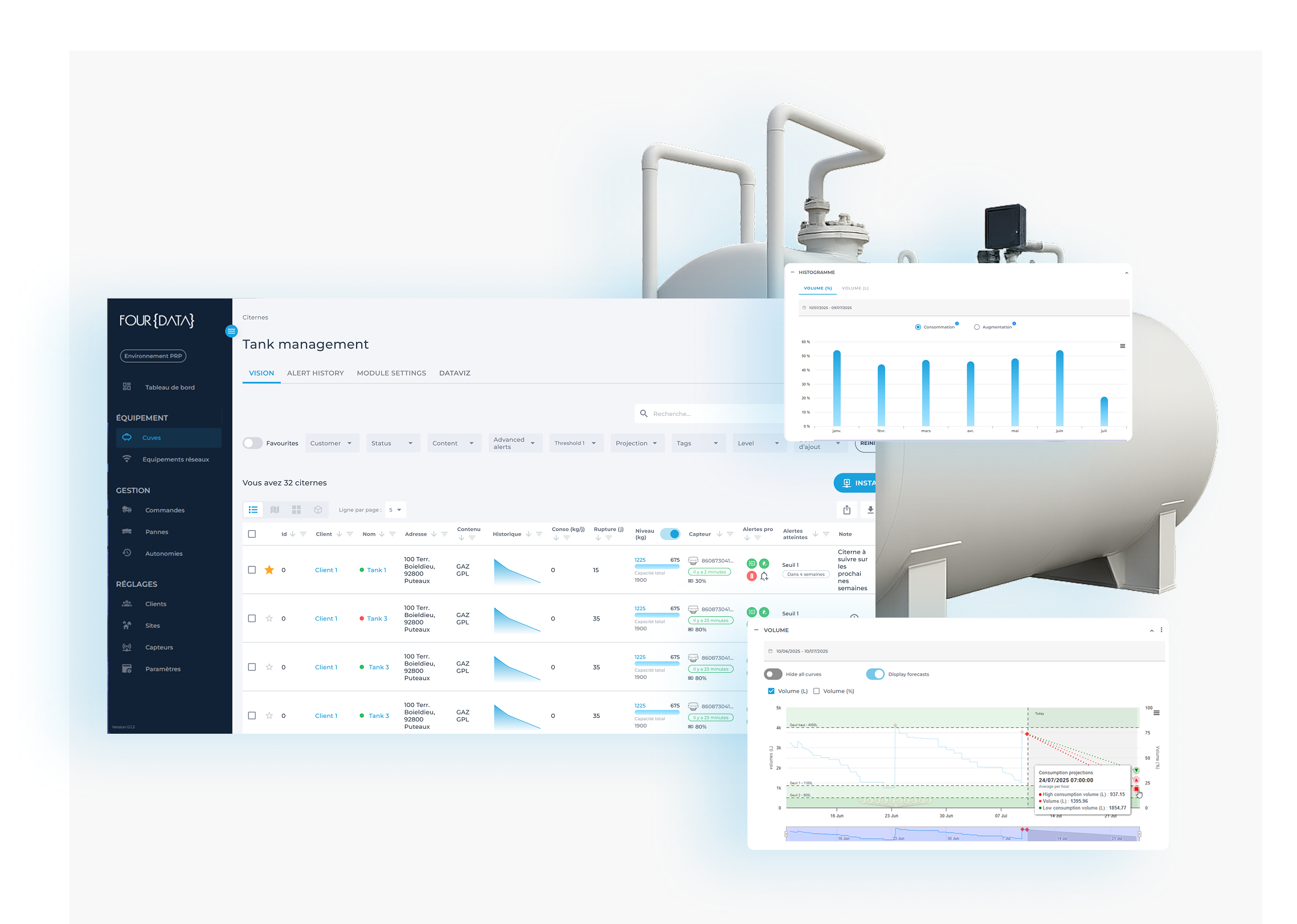

Visualization and alerts via mobile and web applications

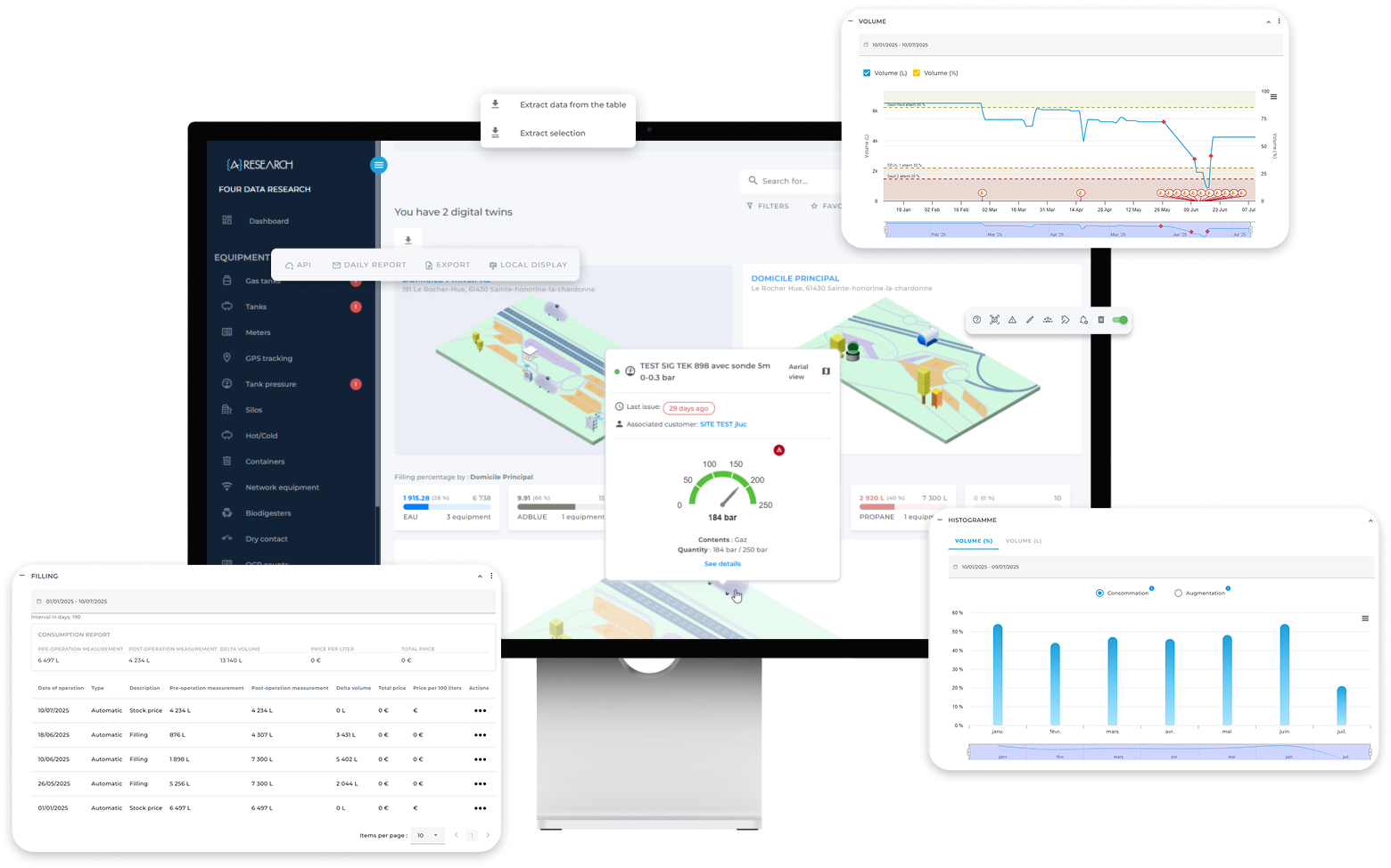

The data is centralized in a management software software:

Clear dashboard with level inconsumption history by day and trends.

Configurable alerts by threshold (e.g. low fuel level) sent by SMS, e-mail or notification.

Multi-tank and multi-site monitoring from a single interface, accessible via mobile or PC.

👉 Inspired by the above example, theintuitive interface interface makes it easy to manage your supplies and orders, while providing a consolidated view of all your tanks.

The concrete benefits of a connected tank

Anticipating disruptions and securing supply

Thanks to real-time monitoring and configurable alerts, you are warned before the level reaches a critical threshold. This enables you to anticipate deliveries and avoid business interruptions.

📊 Up to 35% reduction in breakage observed among users equipped with smart probes.

Optimize inventory management and reduce costs

A connected tank helps you better plan your replenishment and delivery rounds:

Before :

- Scattered manual controls.

- More unnecessary journeys.

- Incorrectly sized stocks.

After :

- Tours optimized according to actual levels.

- Reduce unnecessary travel.

- Less fuel consumption and logistics costs.

👉 The result: direct savings and smoother day-to-day organization.

Improving safety and reliability

Precise level monitoring reduces the risk of overflow, leakage or mishandling. Centralized data guarantee better traceability, reassuring both your teams and your customers.

Connected tank applications

| Sector | Liquids concerned | Key benefits |

|---|---|---|

| Agriculture | Fuel oil, water, liquid fertilizers | Avoid machine breakdowns, manage irrigation, optimize use of resources |

| Industry | Oils, lubricants, solvents, chemicals | Strict traceability, safety compliance, incident reduction |

| Transport & logistics | Fuels, depots, stations, fleets | Delivery planning, multi-site monitoring, business continuity |

| Residential | Oil, water, domestic heating | Assured comfort, low threshold alerts, everyday peace of mind |

Set-up and installation of a connected tank

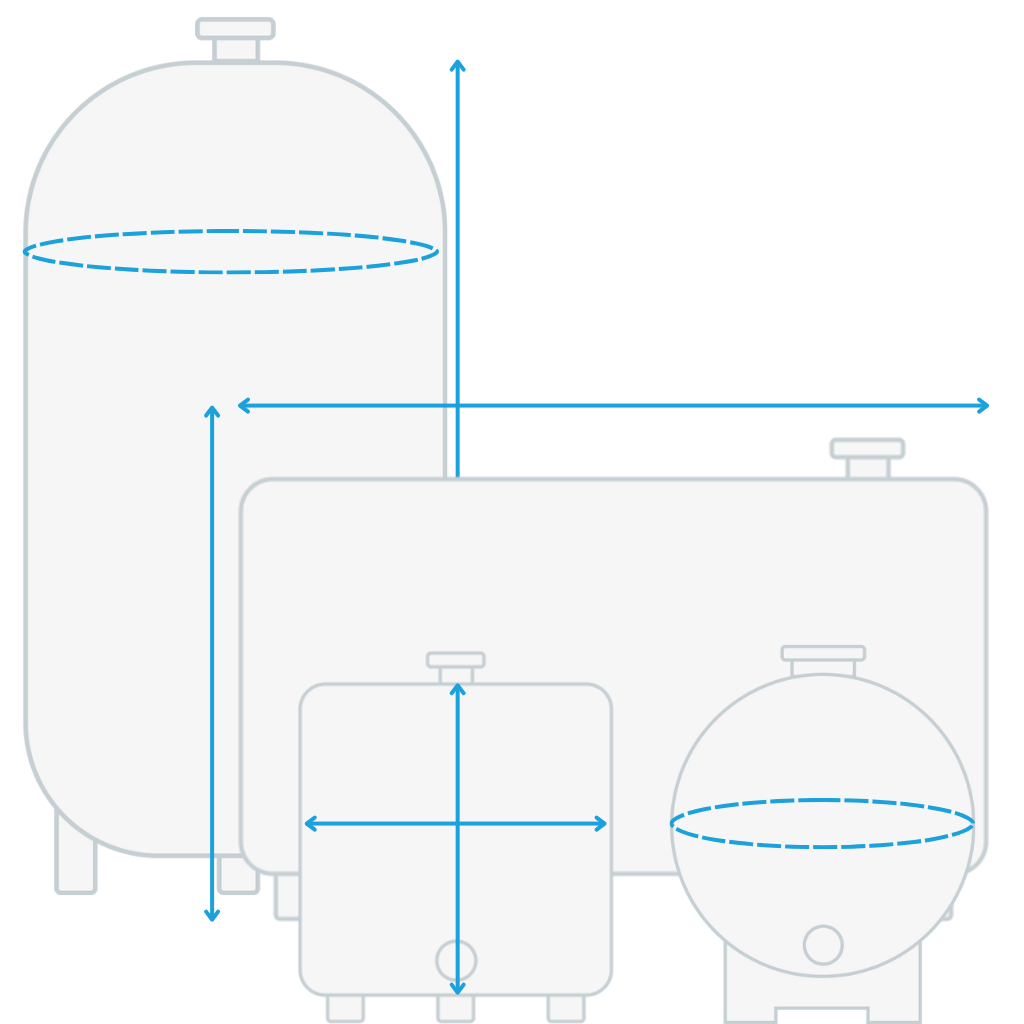

Compatible with different tank sizes and capacities

Our sensors and gauges can be adapted to the majority of tank models available on the market:

- Cylindrical Cylindrical tanks: classic for fuel and water storage.

- Parallelepipedic often used for chemicals and lubricants.

- Buried ideal for saving space and improving safety.

- Large capacities (≥ 10,000 L) as for industrial warehouses.

👉 This flexibility means we can meet the needs of both private individuals and farmers, hauliers and manufacturers.

Quick and easy installation

The installation of a connected tank is designed in Plug & Play :

- Installation of the probe or sensor directly on the tank.

- Immediate commissioning with no major work required.

- Minimal maintenance thanks to long-life battery and robust electronics.

👉 Result: your teams save time and business continuity is preserved, even outdoors.

FOUR DATA support services

A turnkey solution for your connected gauges

Your time is precious. That’s why Four Data offers you a complete solution with specialized technicians toinstall, set up and maintain your connected gauges.

On-site installation & configuration

A technician comes directly to your site to install the gauge, configure the measured storage and link your account. Everything is ready for immediate use.

Management & maintenance of your sensor fleets

Once your connected gauges have been deployed, we provide ongoing monitoring to ensure that each sensor is working properly, detecting any anomalies and taking prompt corrective action to guarantee the reliability of your fleet.

Four Data Academy: expertise and certified training

Your expertise counts. That’s why Four Data has created the Academy, a comprehensive training program for installers of connected sensors, combining theory, field practice and safety.

Training sessions in France & Germany

Our trainers welcome your teams at our centers or directly on site. Each 2-day course combines theoretical training with practical application to guarantee reliable, compliant installations.

A network of qualified and certified experts

We select and certify independent installers close to your areas of operation. Their responsiveness, commitment and ongoing training ensure the success of your deployments and the longevity of your sensor fleets.

Configuration with the Four Data platform

Once the sensor has been installed, the tank is connected to our intelligent management software :

- Customized settings : alert thresholds, frequency of readings, user access.

- Multi-site data centralization View all your tanks in real time from a single interface.

- Fluid integration : connection to your ERP or existing tools via API.

👉 This configuration guarantees simplified and secure management with reliable information available 24/7.

Why choose Four Data for your connected tanks?

Our IoT expertise (hardware & software)

At Four Data, we master the entire IoT value chain value chain: from the design of smart sensors to the development of the software platform.

- Hardware Precise probes (ultrasound, pressure, radar) for all types of tanks and environments (fuel, water, chemicals, outdoor).

- Software multi-site management interface, threshold settings, real-time alerts.

- Multi-sector experience : agriculture, industry, transport, residential → over 1,000 customers equipped and 19,000 connected objects deployed.

👉 This dual know-how hardware & software enables us to offer a complete scalable and reliable solution.

An intuitive, centralized management platform

Our SaaS software is designed to simplify daily tank management:

- Real-time visualization of levels and consumption.

- Configurable alerts sent by SMS, e-mail or mobile application.

- Multi-tank and multi-site access via a single interface.

- Connect to your ERP via API.

👉 A clear interface, inspired by UX best practices, that adapts to your business needs.

Case studies and customer testimonials

Many customers already rely on our solutions to secure their supplies and optimize their operations:

👉 This feedback illustrates the tangible impact of our solutions: fewer emergency deliveries, greater peace of mind and real time savings.

Personalized assistance and support

We support each customer at every stage of the project, with a clear methodology:

- Consulting : needs analysis and project scoping.

- POC (Proof of Concept) Testing in real-life conditions to validate the solution.

- Deployment Quick installation and team training.

- Ongoing monitoring : reactive support, equipment updates and supervision.

👉 With Four Data, you have a long-term long-term partnernot just a supplier.

They trust us:

FAQs on connected tanks

Contact us for a quote and demonstration

Ready to switch to connected tanks?

- Guaranteed response in less than 24h by an expert.

- Personalized demonstration: platform access, sensor presentation, real-life use cases.

👉 Test our solution and discover how we can transform your your tank management into a simple, intelligent and secure process.