IoT in the oil and gas sector: safety, compliance and operational performance

Summary

- Why has IoT become strategic for the oil & gas sector?

- Fundamentals of IoT monitoring in Oil & Gas

- Enhanced operational safety thanks to IoT

- Cybersecurity and reliability of IoT devices

- Regulatory compliance and traceability

- Deployment challenges and best practices

- Criteria for choosing a secure, compliant IoT solution

- Our Four Data approach

- Trends and prospects to watch

- FAQs

- Going further

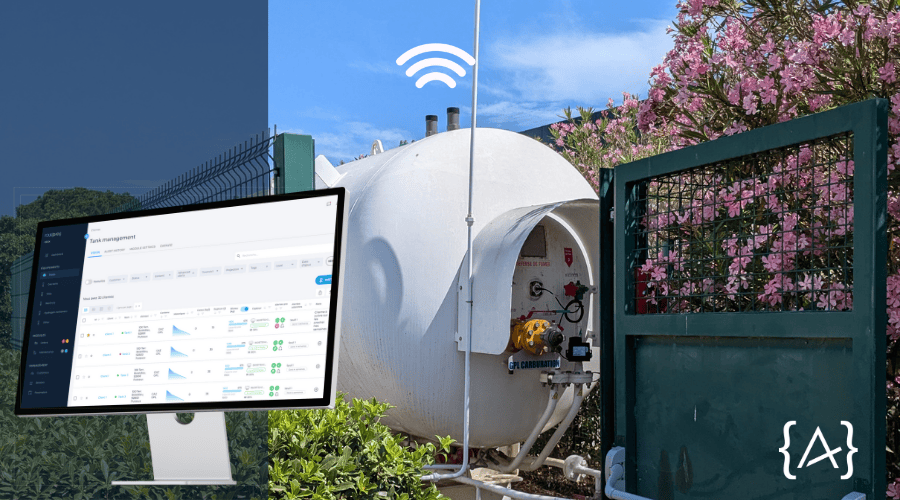

In a sector where the slightest leak or failure can have major human, environmental and financial consequences, continuous monitoring of facilities has become a priority. Thanks to IoT monitoringmonitoring, fuel and gas distributors can now detect anomalies in real time, ensure regulatory compliance and optimize their day-to-day operations.

At Four Datawe support these players in their digital transformation through secure, interoperable and certified IoT solutions.

Committed to quality and sustainability, we are certified ISO 9001 and evaluated by Ecovadisratings, guaranteeing reliability, transparency and sustainable performance.

Why has IoT become strategic for the oil & gas sector?

Faced with complex operations and increasing regulatory requirements, theInternet of Things (IoT) is becoming a strategic lever for reinforcing securitysecurity compliance and performance oil and gas sites. By connecting critical equipment, it becomes possible to obtain continuous visibility of installations, anticipate anomalies and guarantee traceability of actions taken.

Key issues :

- Reducing human, environmental and financial risks.

- Real-time monitoring of infrastructures (tanks, pipelines, stations).

- Automate alerts and centralize data.

- Simplified regulatory audits thanks to reliable, historical data.

- Optimized maintenance and operating costs.

Major risks – leaks, fire, theft, environmental drift

Warehouses and distribution stations are exposed to multiple risks:

- Fuel leaks or overflows leading to pollution and product losses.

- Fires due to overheating or pressure anomalies.

- Fuel theft or intrusion on isolated sites.

- Environmental contamination (water, soil) is costly to remedy.

Regulatory pressure and compliance requirements

Regulations require rigorous monitoring of facilities, from storage to transportation.

| Before IoT | With IoT |

|---|---|

| Manual controls and periodic inspections | Continuous automated monitoring |

| Risk of human error | Time-stamped data and guaranteed traceability |

| Limited reactivity in the event of an incident | Instant alerts and immediate action plan |

From spot checks to 24/7 monitoring

The IoT marks a breakthrough: we no longer control, we continuously monitor. Teams gain in responsiveness and precision, while reducing dependence on manual inspections.

Fundamentals of IoT monitoring in Oil & Gas

The IoT monitoring is based on an ecosystem of connected equipment that continuously measures, transmits and analyzes critical parameters in oil and gas installations. It offers a global, real-time view of the condition of tanks, pipelines, compressors and other strategic assets.

The aim is to turn every piece of data into a lever for anticipating risks, reducing operating costs and reinforcing compliance.

Definition and scope of IoT monitoring

IoT monitoring brings together all the technologies used to remotely monitor equipment of an oil or gas facility. It is based on intelligent sensors capable of collecting physical data (level, pressure, temperature, flow rate, etc.) and transmitting them to a central platform for analysis.

This system provides operators with precise precise and predictive control operations, reducing manual intervention and improving overall safety.

Key sensors and ATEX compliance

Petroleum environments require robust, certified sensors:

- Level sensors to monitor tank filling.

- Pressure and temperature sensors to prevent overheating and leaks.

- Gas detectors to signal hazardous emissions.

- Vibration sensors to anticipate wear and tear on mechanical equipment.

Adapted connectivity

| Technology | Benefits | Use cases |

|---|---|---|

| LTE-M | High responsiveness, wide coverage | Urban sites, interconnected depots |

| NB-IoT | Low power consumption, long range | Insulated tanks, buried sensors |

| Satellite | Total availability, network independence | Areas without mobile infrastructure |

Integration with existing systems

Our IoT solutions integrate natively with supervision systems and business tools (SCADA, ERP, GMAO). This interoperability enables data to be centralized in a single environment, automating alert and maintenance processes.

Enhanced operational safety thanks to IoT

In an environment as sensitive as that of oil and gas, responsiveness is essential. reactivity and reliability of field information are essential. The IoT enhances operational safety by enabling continuous monitoring, automated alerts and rapid analysis of anomalies, ensuring targeted and effective interventions.

In practice, the IoT acts on three essential levers:

- Early detection : intelligent sensors identify any abnormal variation.

- Proactive prevention Suspicious behavior or intrusions are detected instantly.

- Automated intervention: the platform triggers alerts and prioritizes actions.

Leak and fault detection

A network of sensors continuously monitors tank pressure and level. As soon as a potential leak is detected, an alert is sent to the platform.

Intrusion and theft prevention

Motion and vibration sensors detect unauthorized tampering with tanks or access hatches, enhancing safety at remote sites.

Automated alerts and interventions

In the event of an incident, the Four Data IoT platform follows an automatic workflow :

1️⃣ Detection → 2️⃣ Immediate notification → 3️⃣ Prioritization according to criticality → 4️⃣ Dispatch to supervisory teams or systems.

Cybersecurity and reliability of IoT devices

Because every connected sensor represents a potential point of entry, the cybersecurity is an essential pillar of IoT monitoring in the oil and gas sector. The data collected – levels, pressures, alarms – must be protected against any alteration or intrusion.

At Four Datawe apply a “security by design “security by design at every level, from sensor to cloud, to guarantee the integrity, confidentiality and availability of critical information.

Best practices:

- Use secure protocols (HTTPS, TLS, VPN).

- Authenticate each device via unique certificates.

- Segment industrial and IoT networks.

- Schedule regular firmware updates.

- Carry out periodic audits and penetration tests.

Encryption, authentication and updates

Data transmitted by sensors must be end-to-end encryptionThis ensures that no sensitive information is intercepted. Device authentication using digital certificates prevents identity theft. Last but not least OTA (Over The Air) updates ensure rapid correction of vulnerabilities, without the need for physical intervention on site.

Network segmentation and regular audits

To reduce the attack surface, it is essential to isolate IoT networks from office or SCADA systems.

Safety checklist :

- VLAN for connected objects

- Application firewall and IP filtering

- Centralized event logging

- Half-yearly compliance audit

Lifecycle management and incident response

The security of an IoT device doesn’t end with its installation: it must be maintained throughout its use.

| Phase | Key actions |

|---|---|

| Deployment | Security validation, certificates, network integration |

| Operation | Monitoring, updates, intrusion alerts |

| End of life | Access revocation, data deletion, secure replacement |

Regulatory compliance and traceability

In the oil and gas sector, compliance compliance is not limited to the safety of installations: it encompasses traceability of operationstraceability environmental management and data protection.

Thanks to IoT monitoring, operators have a continuous continuous digital record of their equipment’s operation, interventions and controls.

Four Data solutions meet key requirements:

- ISO 9001 standard for process quality.

- ATEX Directive for hazardous areas.

- Local regulations on fuel storage and transport.

Logging and audit trails

Each sensor automatically records its measurements and events (alerts, updates, corrective actions). These time-stamped data constitute a audit proof reliable and usable during inspections.

Regulatory reporting and collaboration with authorities

Four Data dashboards allow you toautomatically export regulatory reports (PDF or CSV format) and share them with regulatory bodies.

Example: a weekly pressure monitoring report consolidating alerts, thresholds and actions taken.

Data governance and RGPD

Deployment challenges and best practices

Deploying an IoT project in the oil and gas sector requires a methodical approach to guaranteeing service continuity and data data reliability. Each site has its own specific features, environmental conditions, infrastructure and regulatory constraints that need to be taken into account right from the design stage.

Best practices to adopt :

- Perform a connectivity audit before deployment.

- Choose certified certified and calibrated sensors for specific fluids and environments.

- Prioritize a scalable architecture (progressive addition of equipment).

- Plan for maintenance and centralized supervision plan.

- Ensure software compatibility with existing systems.

Connectivity for remote areas and edge computing

In areas with little coverage edge computing processes data locally to ensure continuity of analysis without relying on the network. This approach reduces latency and avoids critical information loss.

Sensor reliability and false positives

Environments with high thermal or electromagnetic stress can generate erroneous readings. Regular calibration and redundant measurements guarantee the alert quality.

Scalability and total cost of ownership

IoT must be seen as a sustainable sustainable investment. Modular platforms reduce total cost of ownership (TCO) by simplifying upgrades and the addition of new sites.

Compatibility and gradual migration

For seamless modernization, new sensors can coexist with existing SCADA systems. Batch migration limits risks and enables performance to be validated before generalization.

Criteria for choosing a secure, compliant IoT solution

Choosing an IoT solution for the oil and gas sector is about more than just technical performance. It must also guarantee safetysafety reliability and regulatory sustainability the system deployed. Here are the essential criteria to consider before making a decision:

Material conformity (ATEX)

- Check certification ATEX / IECEx certification for all equipment deployed in hazardous areas.

- Ensure resistance to extreme conditions (temperature, humidity, pressure).

Protocols and security by design

- Use of secure secure protocols (TLS, MQTTs, VPN).

- Encryption of data as soon as it is collected and authentication of sensors.

Integrated auditability

- Complete history of alerts, interventions and updates.

- Automatic export of event logs for internal and external audits.

Distributed architecture

- Modular platform, multi-site and redundantguaranteeing service continuity.

Support, SLA and business model

- Clear service contract : SLA, maintenance, 24/7 support.

- Flexible model (purchase, subscription or SaaS) to control total cost of ownership (TCO).

Our Four Data approach

At Four DataWe design and operate tailor-made IoT solutions that can be adapted to the diversity of oil and gas sites. Our approach is based on complete control of the value chain, from sensor to data, to guarantee the reliability, compliance and performance of each installation.

An Oil & Gas agnostic IoT platform

Our platform centralizes all data from heterogeneous sensors (level, pressure, gas, etc.) and adapts to all communication protocols.

Project methodology (5 steps)

1️⃣ Understanding needs

2️⃣ POC design

3️⃣ Field deployment

4️⃣ Industrialization

5️⃣ Ongoing monitoring and optimization

Key modules: supervision, BI, compliance

Dashboards, automated alerts, audit reports and performance indicators.

Multi-site integration and sensors

Unified management of complex fleets: depots, service stations, pipelines or remote tanks.

Trends and prospects to watch

The oil and gas industry is continuing its digital transformation, driven by emerging technologies that enhance safetysafety resilience and traceability IoT operations. These innovations are redefining the way critical infrastructures are supervised, analyzed and made reliable.

AI and predictive maintenance

Artificial intelligence analyzes weak signals from sensors to anticipate breakdowns before they occur, optimizing maintenance and limiting unplanned downtime.

Edge computing

Local data processing (at the edge of the network) ensures continuity of analysis, even without a cloud connection, and real-time reaction.

Blockchain

Blockchain guarantees tamper-proof traceability of sensor data and interventions, reinforcing regulatory compliance.

Digital twins

Virtual plant models can be used to simulate scenarios and adjust settings to maximize safety and efficiency.

FAQs

Going further

Explore our IoT solutions designed for tank, depot and pipeline supervision. You’ll find our ATEX-certified technologies, use cases and field expertise.

You may also be interested in these articles :