OPTITRACK VISION – the connected intelligent vision system for gas racks and tippers

Managing gas racks and collection bins is a major challenge for companies and local authorities. Lack of visibility on stocks, unnecessary journeys, site safety, maintenance costs: these are just some of the challenges to be met on a daily basis.

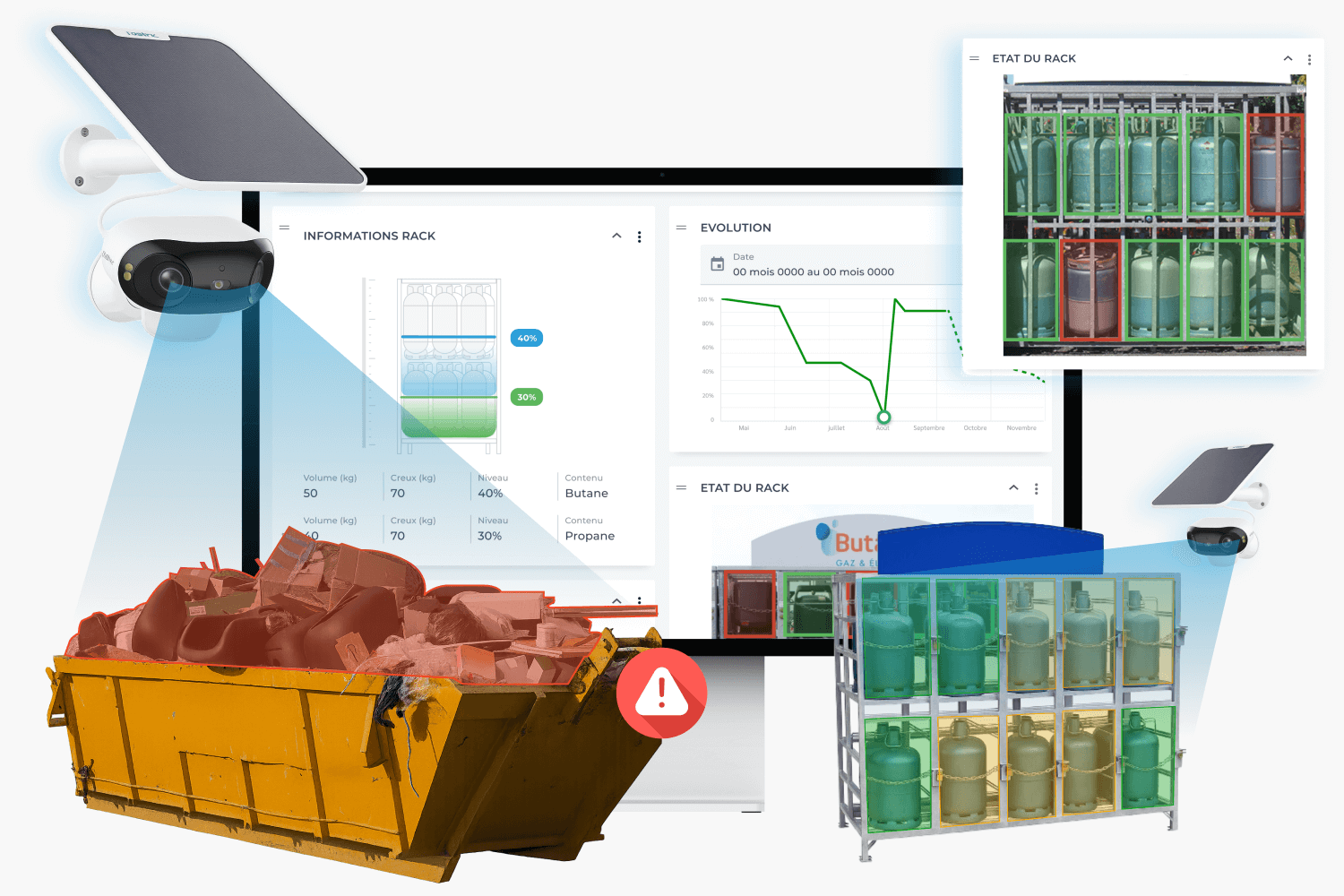

With OptiTrack Visionwe offer a autonomous and connected computer vision solution capable of measure, count and analyze in real time the filling level or the quantity of equipment present.

Based on a photovoltaic panel-powered smart camerathe solution operates efficiently and efficiently and sustainablyeven in isolated environments.

What is OptiTrack Vision?

An intelligent vision solution for measuring, counting and forecasting

OptiTrack Vision is based on computer vision andartificial intelligence to ensure to remotely count and measure of your equipment: gas racks, skips, big bags or pallets.

The connected optical cameras capture images at regular intervals; an image analysis algorithm automatically detects fill levels, available volumes and the presence of anomalies.

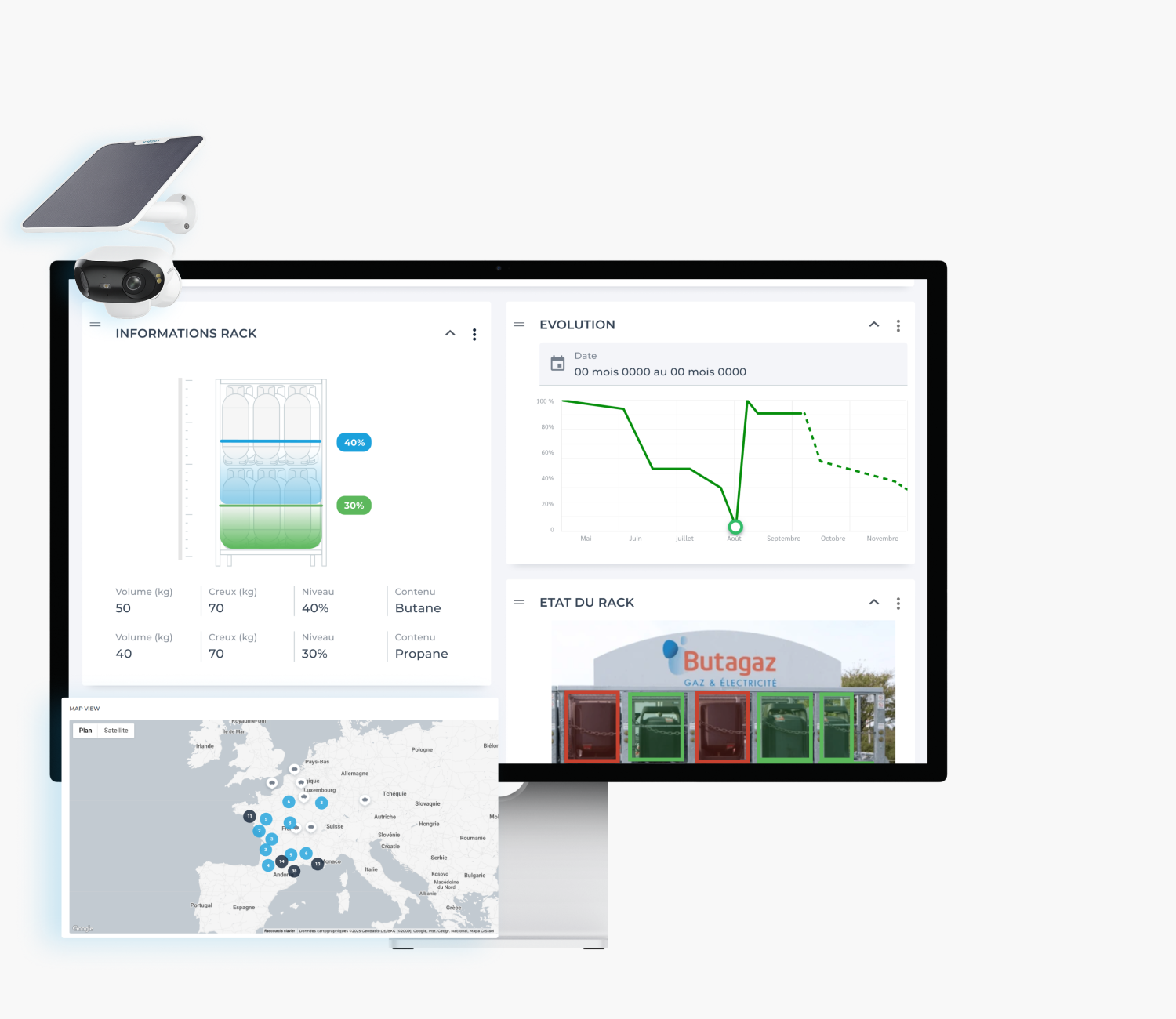

The data is then transmitted via IoT networks (LoRaWAN, Sigfox, NB-IoT) to the Four Data platformplatform, where they are visualized in real time to facilitate planning and operational monitoring.

Why adopt OptiTrack Vision?

- Total visibility on your inventory and fill levels.

- No more manual readings and unnecessary travel.

- Optimization of delivery and collection routes.

- Reduce the carbon footprint of your activities.

- Energy self-sufficiency thanks to integrated solar panel.

⚡ Problem → Solution

Problem : incomplete data, empty runs, wasted time and lack of visibility.

Solution: an intelligent, autonomous and durable system that continuously collects, measures and transmits your field data.

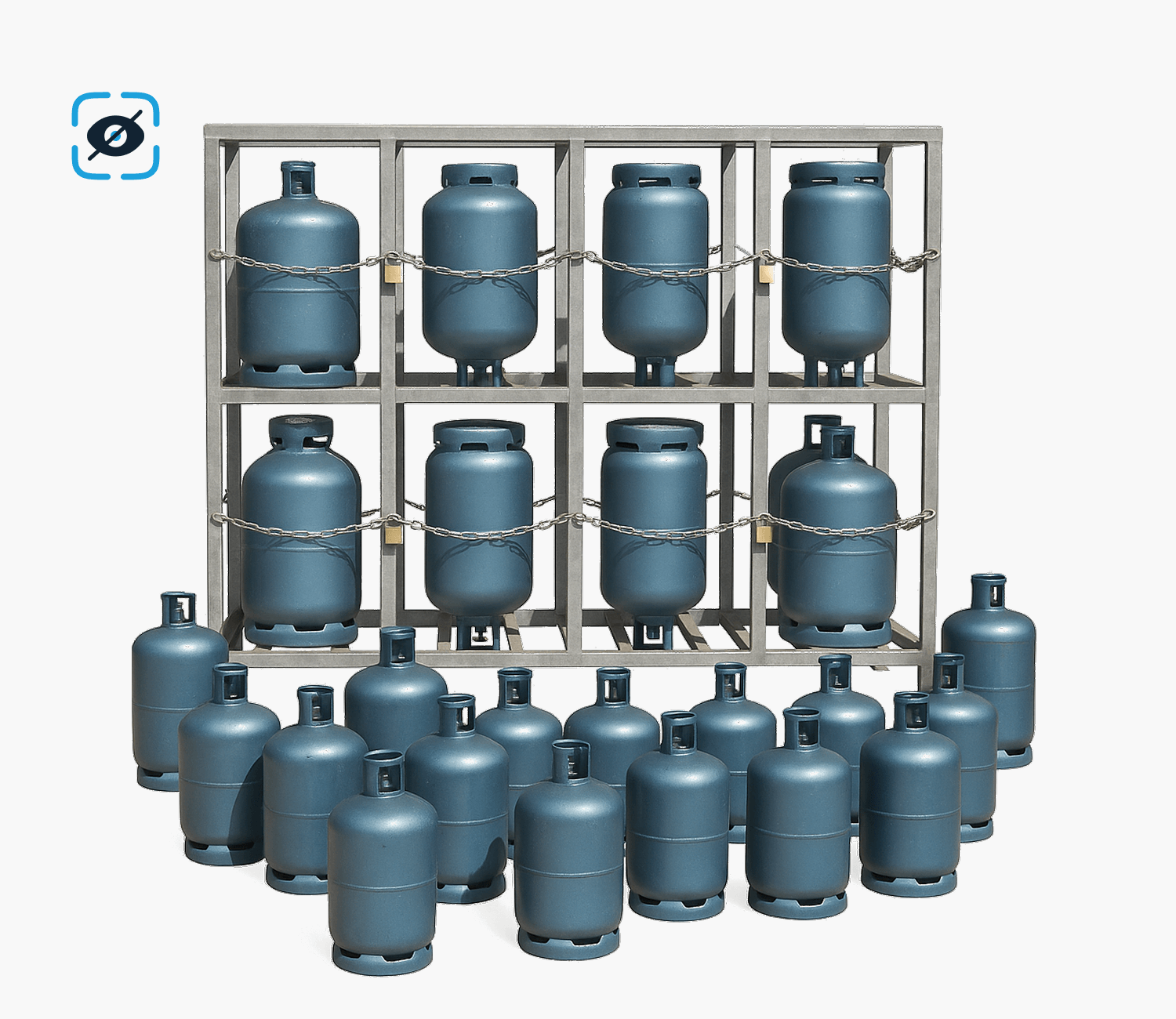

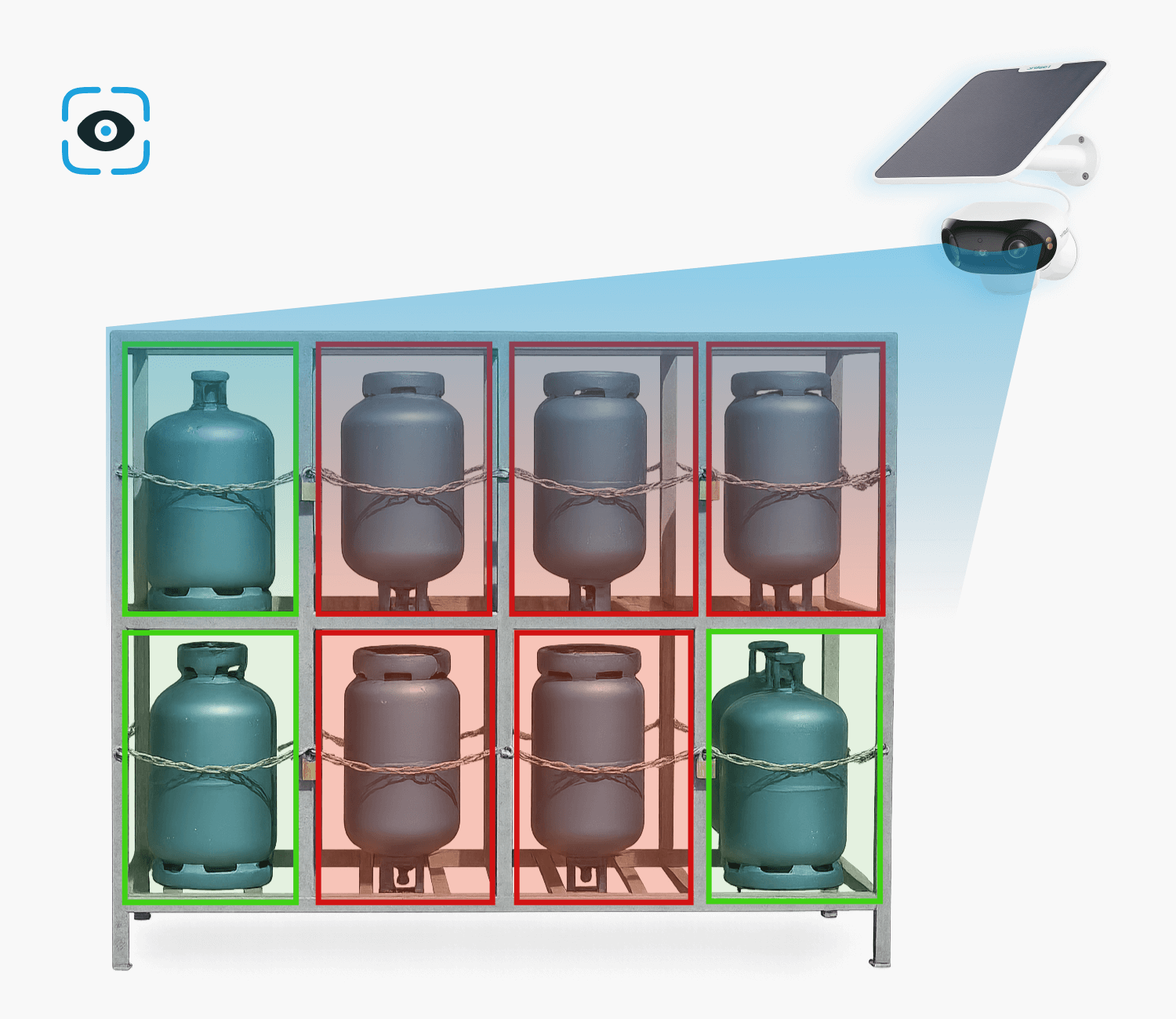

Use case 1 – Monitoring gas racks

The challenges facing cylinder managers

For maintenance managers, distributors or logisticians, visibility of visibility of stock levels on bottle racks is crucial.

Between safety, rotation rate, replenishment and recycling cycle, every bottle not properly monitored can lead to service disruption or economic loss.

Manual readings are time-consuming and unreliable, especially in hard-to-reach or multi-point areas.

The OptiTrack Vision solution

OptiTrack Vision provides automated automated bottle stock monitoring.

A smart camera installed on site captures images at regular intervals.

The analysis algorithm identifies full, empty or missing bottlesand transmits the results to the Four Data platform.

From configurable alerts warn when a critical threshold is reached: need for replenishment, anomaly detected or rotation change.

Thanks to IoT connectivity connectivity and integrated photovoltaic panelthe solution remains autonomous, economical and easy to deploy.

It also contributes to your CSR OBJECTIVES objectives: fewer journeys, lower emissions and more sustainable operations.

Our other solution that might interest you:

Four Data’s OCR sensor is a device that attaches directly to a mechanical gas meter (old or standard) and uses a camera + optical recognition algorithm to transform the analog display into connected digital data (NB-IoT, LoRa, Sigfox, LTE-M or Wi-Fi).

This solution automates remote readings, improves data reliability and reduces manual intervention in constrained industrial environments.

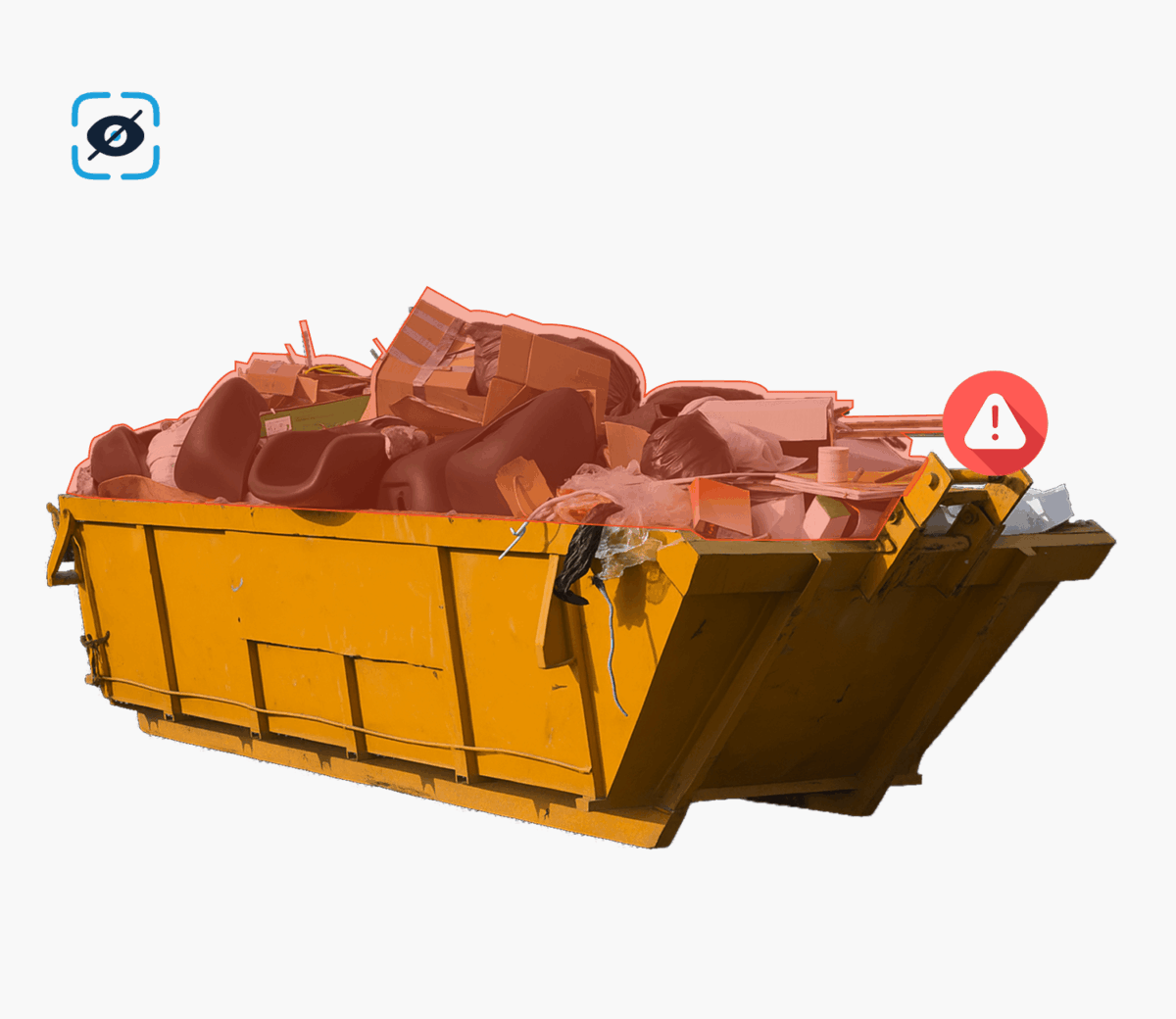

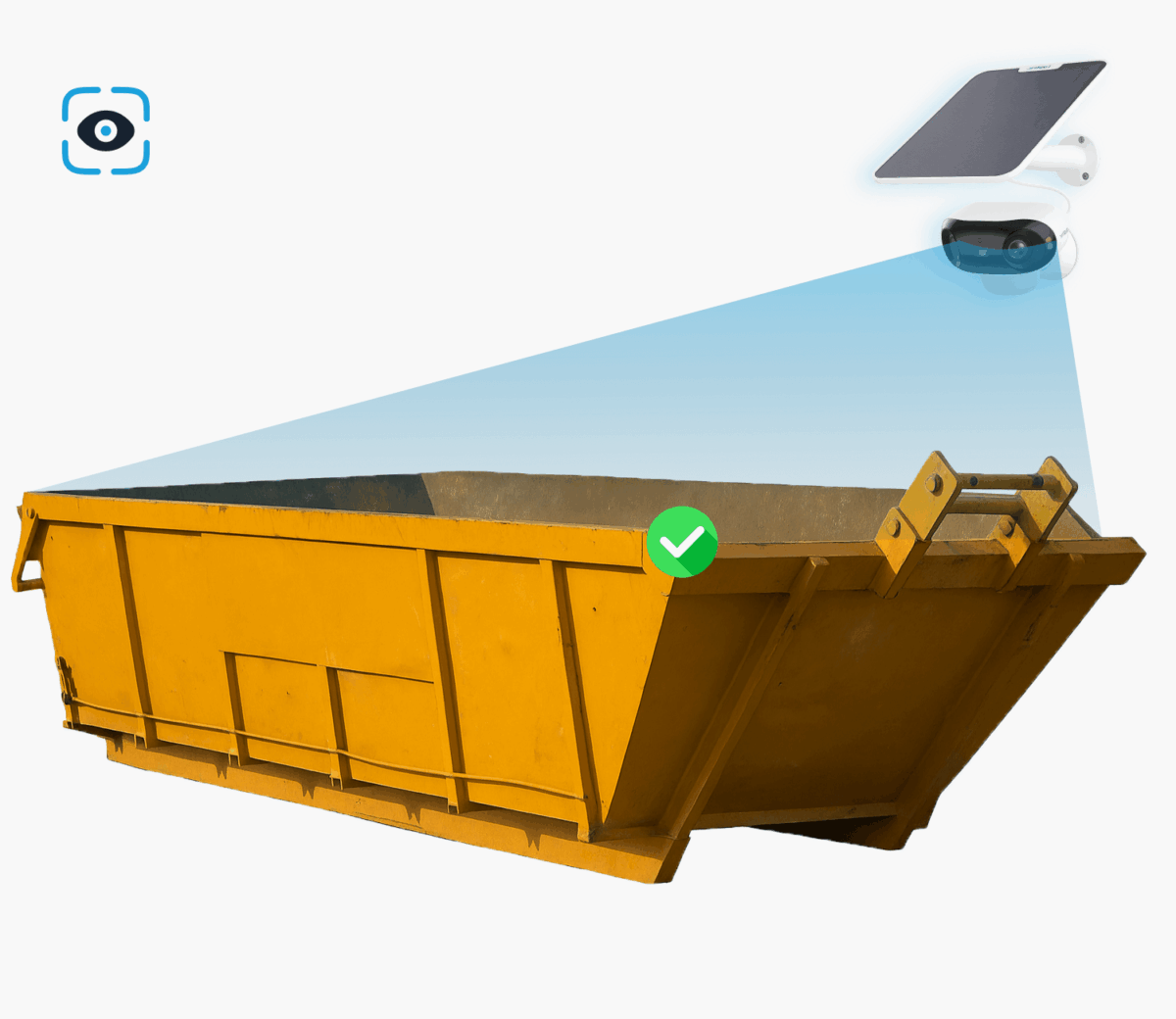

Use Case 2 – Monitoring skip filling

A clear vision for optimized collection

For local authorities and industrial operators, the tracking skip fill levels to adapt routes to actual needs.

OptiTrack Vision detects levels, quantities, materials and anomalies (rubble, cardboard, scrap metal, green waste…).

The images captured by the camera are analyzed by AI, and the level data are transmitted to the Four Data IoT platform.

The system also identifies illegal dumping and abnormal behavior on site, improving safety and the responsiveness of technical services.

Benefits observed

- Average 30% reduction in collection routes.

- Reduced carbon footprint and operating costs.

- Instant alerts when filling thresholds are reached.

- Improved agent comfort and user satisfaction.

A complete IoT platform to centralize data

The Four Data IoT platform platform brings together all information from deployed cameras and sensors.

It offers :

- a centralized view on your skips, racks or other containers;

- a customized dashboard to track key indicators;

- a measurement history for analysis and planning;

- of customizable alerts according to your needs (level, stock, material, frequency).

Compatible with existing IoT networks, the platform is equally well suited to a pilot project pilot project large-scale industrial deployment.