Connected oil gauge Belgium : monitor your tank remotely and optimize your consumption

The price of heating oilheating heating oilor GNRremains a major issue for many households and businesses in Belgium. Yet many people are unaware of the actual level of their oil tankrisking breakdown at the least opportune moment.

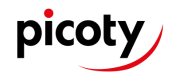

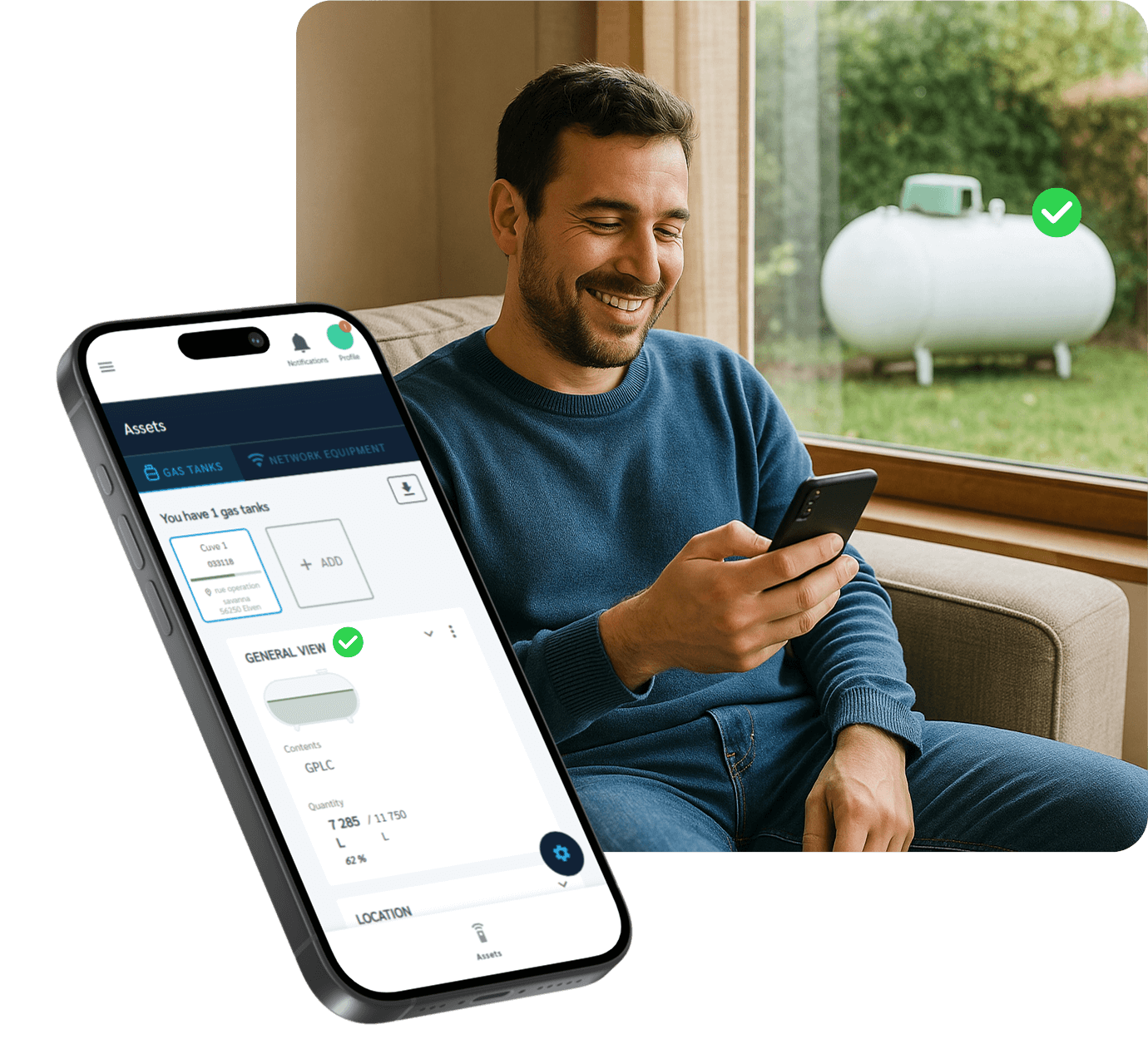

Thanks to our connected gaugeyou can monitor in real time the level of your tank and avoid any rupturewhatever the type of fuel fuel fuel or biofuel used.

Unlike other players who limit themselves toultrasound, Four Data offers a wide choice of sensors (ultrasonic, pressure, multi-network IoT) to suit your specific configuration configuration of each tank.

The individuals can, if they wish be connected to their local distributor to facilitate automatic replenishment.

TABLE OF CONTENTS

- Understanding the connected oil tank gauge

- Why fit your tank with a connected gauge?

- Choosing the right connected gauge for your needs

- The Four Data solution: control your oil gauges with the IoT

- Understanding

- Ideation

- POC

- Deployment

- Follow-Up

- FAQ – Frequently asked questions about the connected oil tank gauge

- Adopt the Four Data connected gauge and keep an eye on your tank in Belgium

Understanding the connected oil tank gauge

What is a connected gauge and how does it work?

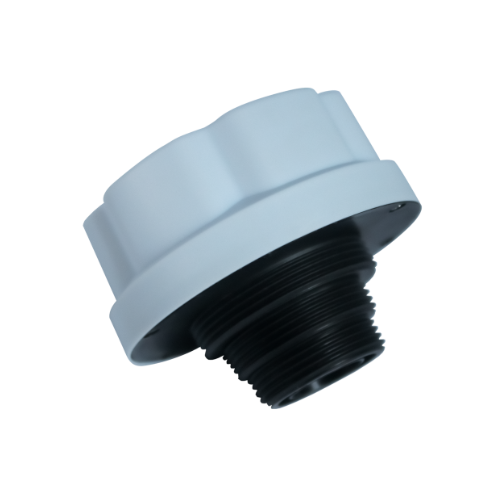

A fuel gauge is an smart sensor that provides know in real time the oil level in your tank. It works on a simple principle: the sensor measures the height of the liquid inside the tankconverts this information into volumethen transmits it via an IoT network network to a mobile interface or a web platform.

Thanks to this technology data accessible at any time: you can track your consumptionanticipate your needs, and avoid breakdowns. In Belgium, this type of connected solution is perfectly suited to both domestic and professional installations.

💡 Myth vs. reality

A connected gauge doesn’t just display the level: it analyzes the data to anticipate needs.

Technologies used: ultrasonic, pressure, IoT and ATEX sensors

Our connected gauges adapt to every type of oil tank or vatwith a wide choice of measurement technologies and IoT networks.

They are suitable for individuals and professionalsand can be fitted to tanks for fuel oil, GNR, water, gas or biofuelsincluding in ATEX (environments.)

Need an ATEX solution? Four data offers a range of tank-compatible sensors, ATEX tank as well as gas meter.

→ ideal for kerosene, sp98 sp 95,LPG, propane, butane etc!

Installation and compatibility with different types of tanks

In 70% of cases, installingan intelligent tank gauge requires no special technical skills.

Simply screw screw the sensor onto the existing orifice, start it upand then connect to the mobile application.

Visit Four Data solutions are compatible with the majority of tanks steel, plastic or concrete tanks, whether underground or above-groundand are also suitable for gas tanks and ATEX environments.

Pre-installation checklist

- Check tank type and volume

- Monitor IoT network availability

- Ensure tightness system

- Follow the instructions step-by-step installation instructions

Installation & training

Four Data provides a network of approved field installers installers to guarantee fast, safe commissioning.

For professionals wishing to improve their skills, the FOUR DATA ACADEMY offers technical training dedicated to the installation, maintenance and configuration of IoT sensors.

Point of caution

Always check waterproofing and network connectivity before installation, to ensure reliable measurements.

Why fit your tank with a connected gauge?

Automatic tracking and alerts

Thanks to the connected gaugegauge oil level is now monitored in real timewithout manual intervention. The user automatically receives notifications and alerts when the oil level reaches a low level, helping toavoid any breakdown of heating system. Data is continuously updated and accessible from the application mobileoffering ease of use comfort.

Anticipating orders and saving fuel oil

Tracking the evolution of stockthe fuel gauge helps to anticipate orders with your supplier. No need to wait for break you plan your replenishments at the right time, according to your real needs. This makes it possible to reduce costs and avoid high-priced purchases.

💰 Key benefit

Up to 15% savings thanks to optimal timing of orders.

Centralized management via application or web platform

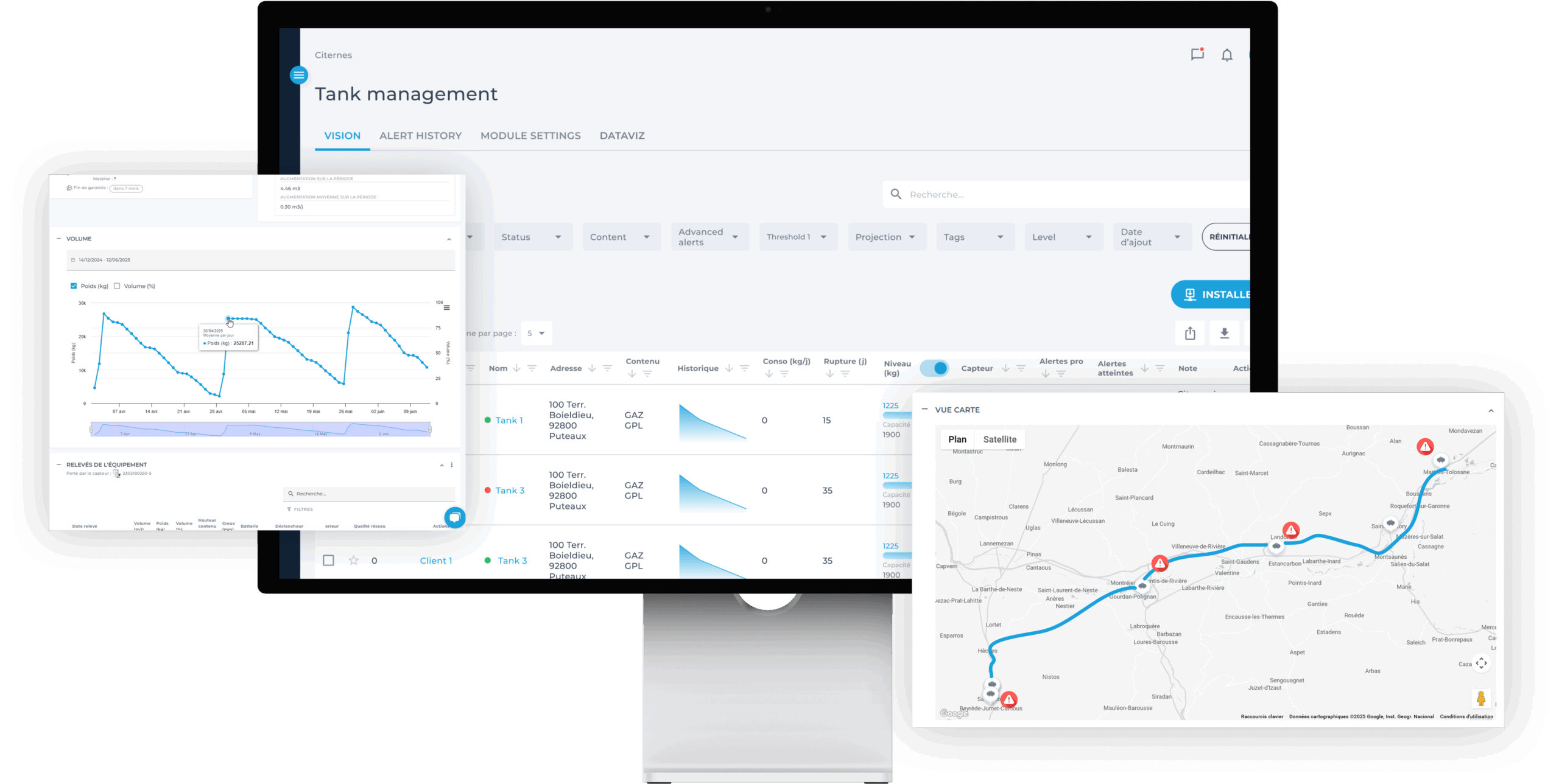

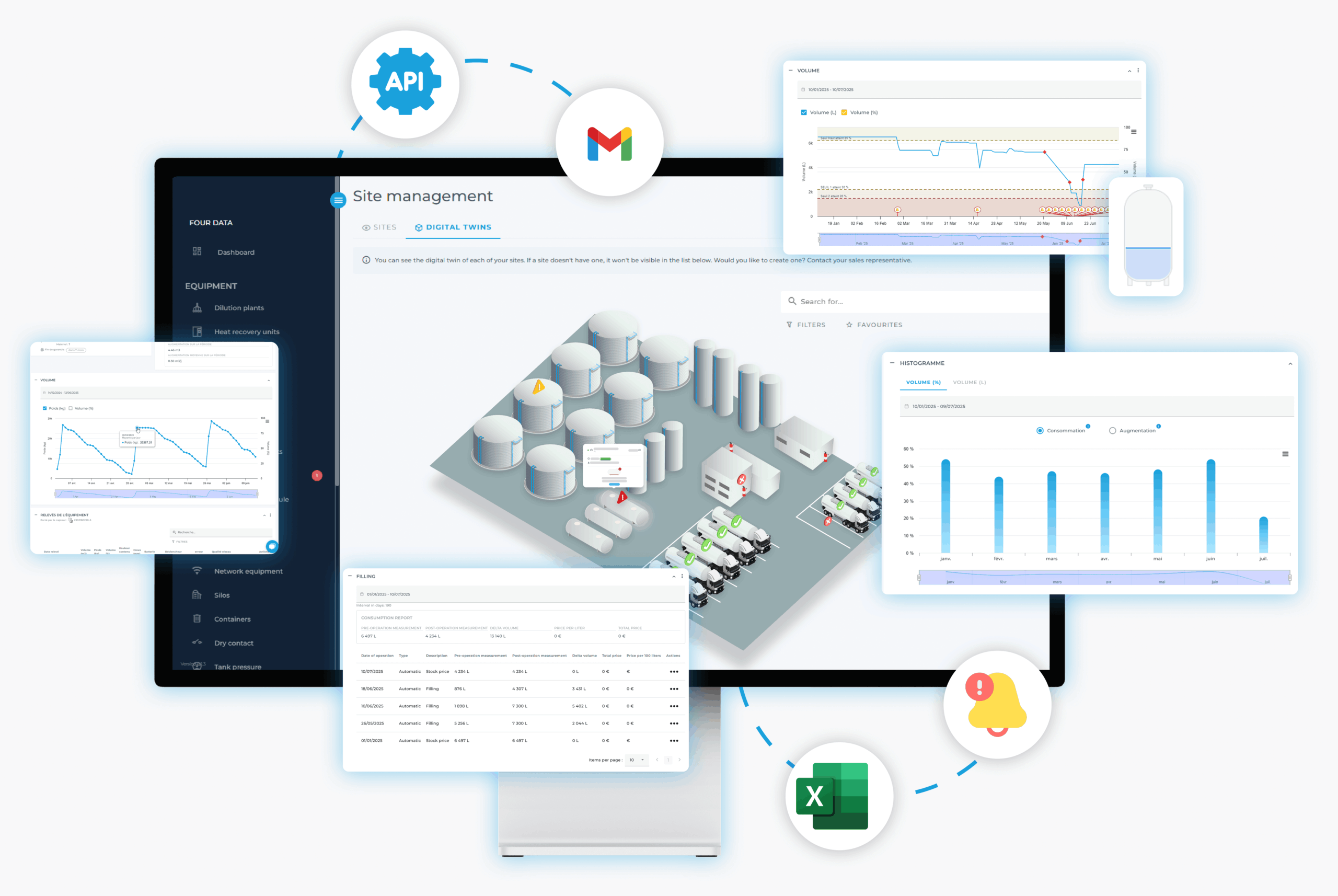

The Four Data solution solution track several tanks or oil tanks from a single interface. Via an intuitive dashboard, you can consult the datamanage alertsand access consumption statistics consumption statistics. Integrated APIs make it easy to direct connection with other business tools for fluid, multi-site supervision.

Contributing to more responsible and sustainable consumption

The connected gauge helps you management of heating oil. By adjusting controls and monitoring leaks leaks, it helps to reduce waste andcarbon footprint. In Belgium, this approach is fully integrated into the energy transition for individuals and businesses alike.

🌍 Case study

An industrial customer reduced its delivery trips by 12% thanks to IoT tracking.

Choosing the right connected gauge for your needs

Essential criteria: tank type, connectivity, autonomy, precision

Before investing in a fuel gaugeit is essential to assess the compatibility of your installation. Visit tank type (underground, overhead, steel or plastic), the available IoT network network (Sigfox, LoRa, NB-IoT), and theautonomy of fuel sensor directly influence the quality of data received.

On average, a Four Data gauge offers a service life years, without complex maintenance.

| Criteria | Detail | Importance |

|---|---|---|

| Tank type | Overhead, underground, plastic, steel | Compatibility to be checked |

| IoT network | Sigfox, LoRa, NB-IoT, LTE-M | Stable connection essential |

| Operating life | 3 to 5 years depending on battery and use | Durability and reliability |

| Accuracy | ±1% depending on sensor | Reliable data for monitoring |

Comparison of solutions available on the market

The Belgian market boasts several players specializing in connected oil tank gauges. Here’s an overview of the main technologies:

| Brand | Technology | Specificity |

|---|---|---|

| IoT Link | Ultrasonic sensor | Dedicated mobile application, simple solution for home users |

| Full Up | Ultrasonic sensor | Automatic alert function, without centralized management platform |

| Four Data | Multi-sensors (ultrasonic, pressure, ATEX) + IoT platform | Complete solution: sensor, network, data, service +, connection to your distributor possible |

The strength of Four Data lies in its complete integration to all-in-one solutionfrom measurement toinformation analysiswithout relying on a third-party supplier.

In addition, we offer the possibility of connecting consumers directly to their oil distributor of choicein order to simplify replenishment andavoid stock-outs.

⚠️ Common mistake

Comparing price alone without considering network compatibilitynetwork associated and integration quality.

How do you select the solution best suited to your needs (private or professional)?

The right choice depends on user profile and the actual need :

- Individual Prioritize ease of installation, l’mobile application and automatic alerts.

- Professional / operator give priority to multi-tank managementmanagement data centralization and long-range long-range connectivity.

- Distributor or supplier: choose a solution compatible with your supervision systems and logistics tracking tools.

The Four Data solution: control your oil gauges with the IoT

Our IoT expertise: from data capture to data enhancement

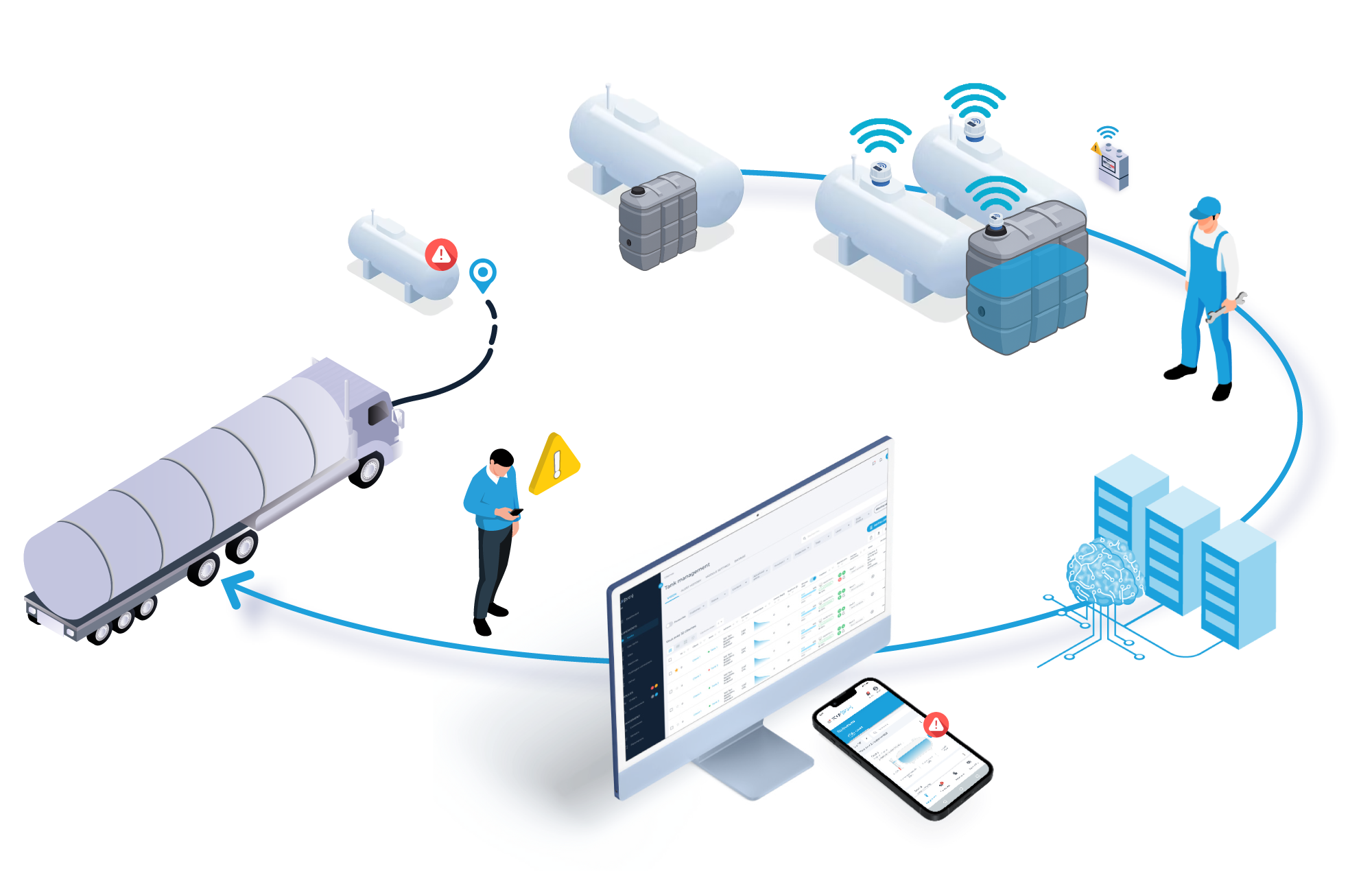

At Four Datawe master the entire IoT chain, from the fuel sensor to the analysis platform.

Our connected gauges precisely measure the oil level or other liquidsthen transmit the data via IoT networks (Sigfox, LoRa, NB-IoT, LTE-M). This information is then analyzed in the form of graphs, trends and intelligent intelligent alerts to monitor consumption and anticipate needs in in real time.

This end-to-end guarantees consistent measurement quality and a unified view of your tankseven across several sites in Belgium.

🧠 Expert advice

Centralizing data from several sites on a single interface boosts energy performance.

Integration with our platform for simplified, multisite management

Our IoT platform provides a complete overview of your fleet of oil tanks.

You have access to a clear dashboarddashboard levels, alertsand consumption trendsall updated in real time.

Compatible with various sensor typesthe solution is suitable for all sectors of theindustryindustryagricultural and logistics.

In just a few clicks, our customers can track their inventory and avoid any stock-outs effortlessly.

A dedicated offering for the oil & gas sector

Specially designed for players in the energy sectorour connected solution can be integrated into the most demanding environments.

Operators and distributors benefit from a precise precise tool for measure volumes, prevent leaksand optimize delivery rounds.

This global approach improves traceability of heating oil and operational operational performance of installations in Belgium.

🔍 Please note

Four Data’s Oil & Gas offer is aimed at both operators and distributors.

Full support: design, testing, deployment, maintenance

From the defining the need to data supervisionwe support our customers every step of the way:

This methodology guarantees simple installationinstallation, rapid implementation and lasting service service.

They trust us:

FAQ – Frequently asked questions about the connected oil tank gauge

Adopt the Four Data connected gauge and keep an eye on your tank in Belgium

Thanks to the connected gauge Four Data, easily monitor your fuel oil levelanticipate your orders and gain in peace of mind.

Our IoT solutions solutions are designed for individuals, businesses and Belgian operators who want intelligent management of their tanks and fuel oil tanks.

👉 Contact our IoT experts today for a free demonstration and find out how to optimize your consumption with ease.