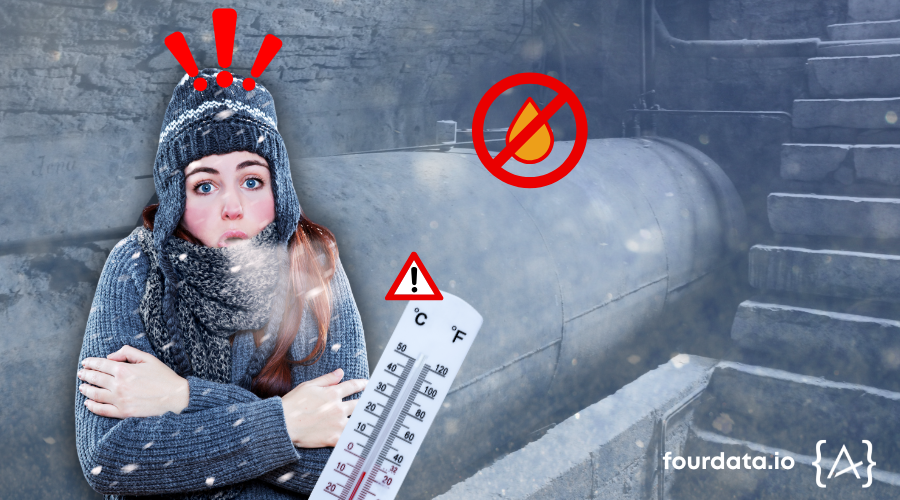

Winter is coming: monitor your tank remotely to avoid heating breakdowns with a connected tank gauge ❄️

Summary

When temperatures drop, a heating breakdown becomes more than an inconvenience—it can be an emergency. Running out of heating oil, paying for expensive last-minute deliveries, or guessing your tank level manually can all be avoided thanks to the connected tank gauge, a modern solution based on IoT technology and a precise level sensor.

Whether you’re a homeowner heated with oil, a property manager, a farm operator, or responsible for an industrial site, remote monitoring is now your best ally to get through winter with peace of mind.

What is a connected gauge for a heating oil tank?

A connected tank gauge is an ultrasonic measurement system or wireless level sensor installed on your tank. It allows you to:

-

measure the tank level in liters,

-

send data automatically via a radio transmitter,

-

view the level on a mobile interface or dashboard,

-

receive custom alerts (low level, leaks, abnormal consumption),

-

access detailed consumption history.

This solution combines measurement precision, wireless technology, real-time tank monitoring, and compatibility with many liquids.

How does a connected oil tank gauge work?

1. Accurate measurement inside the tank

Sensors typically use:

-

ultrasound (wireless ultrasonic gauge),

-

hydrostatic pressure,

-

or radar

Our connected gauges adapt to every type of oil tank or vat with a wide choice of measurement technologies and IoT networks.

They are suitable for individuals and professionalsand can be fitted to tanks for fuel oil, GNR, water, gas or biofuelsincluding in ATEX (environments.)

Need an ATEX solution? Four data offers a range of tank-compatible sensors, ATEX tank as well as gas meter.

→ ideal for kerosene, sp98 sp 95,LPG, propane, butane etc!

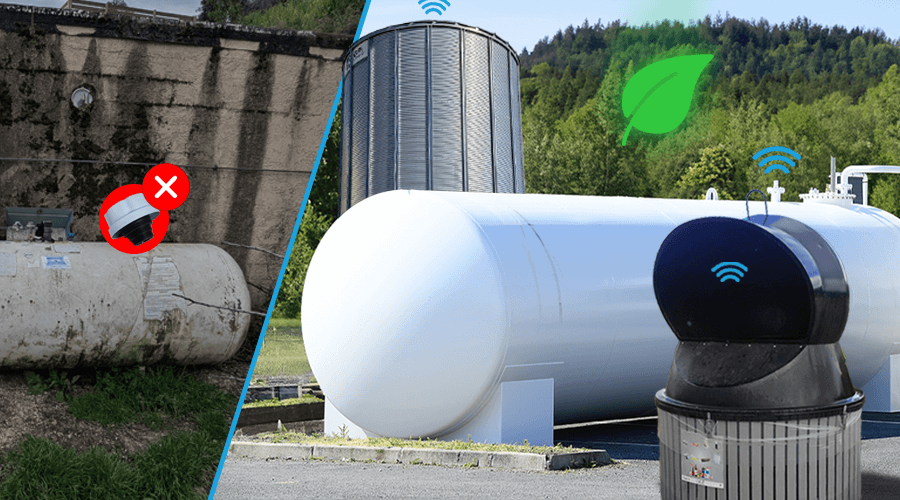

2. IoT network transmission

Data is transmitted via Sigfox, LoRa, NB-IoT, or LTE-M.

Benefits:

-

long battery life,

-

reliable communication in remote areas,

-

strong resistance to environmental conditions.

3. Real-time management interface

Via a web interface or mobile app, users can see:

-

real-time tank level,

-

consumption charts,

-

reporting and history,

-

alerts for leaks or abnormal usage,

-

personalized reports,

-

supply planning tools.

How much does a connected oil gauge cost?

Pricing depends on:

-

the sensor technology (ultrasound, pressure, radar),

-

type of IoT network,

-

tank type and capacity,

-

optional features (API, ERP integration, multi-site dashboards).

Four Data provides pricing on request because every installation is unique.

The investment pays for itself through:

-

delivery optimization,

-

reduced heating costs,

-

better energy management,

-

fewer emergency interventions.

Which types of tanks are compatible?

Residential tanks

-

Heating oil tanks

-

Above-ground or underground tanks

-

Cylindrical or rectangular designs

Professional tanks

-

Agricultural fuel tanks

-

Industrial tanks (oils, lubricants, solvents)

-

Logistics depots

-

Multi-tank installations

-

Various liquids: oil, water, chemicals, fertilizers, etc.

What are the benefits compared to a manual gauge?

24/7 remote monitoring

No more manual checks.

Cost reduction

No more manual checks.

Consumption alerts and breakdown prevention

Avoid running out of heating oil without warning.

High reliability

Precise measurements, data history, leak detection.

Environmental performance

Reduced carbon footprint through optimized logistics.

Multi-site management

Centralized reporting for professionals.

Are you a homeowner? Four Data connects you directly with your preferred fuel supplier

If you are a private homeowner, Four Data can also connect your tank directly to your preferred heating oil distributor.

By enabling secure data sharing, your supplier can automatically receive your tank level information and offer smart, automated order proposals based on the thresholds you set.This means:

no more worrying about running out of heating oil,

no more monitoring your tank manually,

no more last-minute, high-cost emergency deliveries,

optimized refill timing aligned with your real consumption,

long-term savings and greater peace of mind.

This seamless connection between your connected tank gauge and your supplier brings a new level of convenience and automation to residential heating oil management—making it one of the smartest ways to prepare for winter.

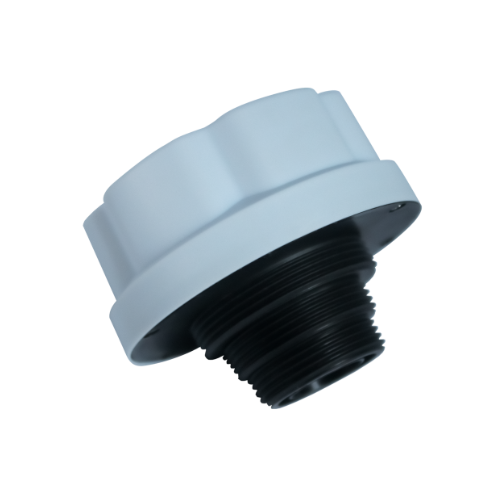

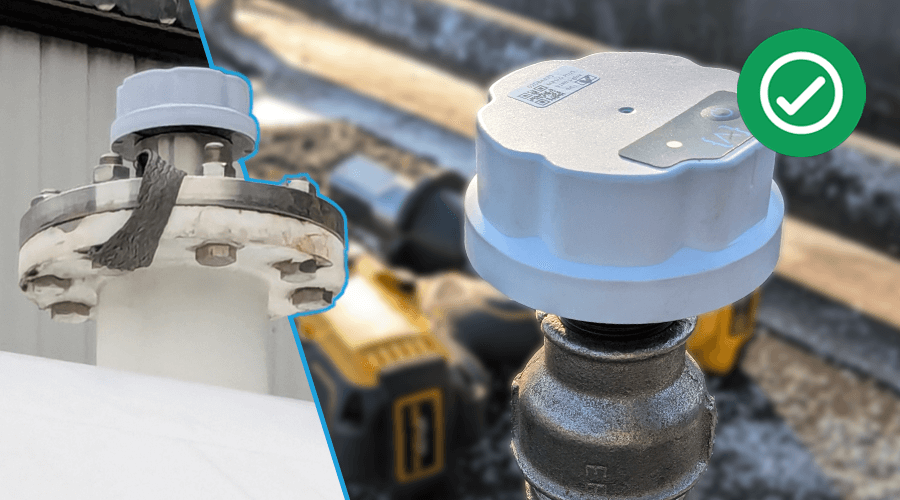

Is installation simple?

Yes. Installation requires:

-

no modification to the tank,

-

plug-and-play setup,

-

just a standard opening (2”, 1” 1/2, 1”1/4),

-

no wiring thanks to wireless technology,

-

optional technical support from Four Data.

Four Data offers a turnkey installation service

Four Data provides a fully turnkey installation service to ensure your connected tank gauge is operational from day one. A certified installer can visit your home or facility in less than 4 weeks* to perform:

-

professional mounting of the sensor,

-

configuration of the connected tank gauge,

-

activation of the IoT network,

-

testing and verification of accurate level measurement,

-

setup of your mobile or web monitoring interface.

This service guarantees a fast, reliable, and perfectly calibrated installation, ensuring your connected tank gauge delivers the highest level of precision, performance, and remote monitoring capability.

*Lead time may vary depending on the country.

This turnkey offer strengthens Four Data’s position as a trusted provider of connected tank solutions, helping homeowners, farmers, industrial sites, and property managers benefit from a smooth, worry-free setup.

Four Data Academy: on-site training for professionals

For fleet managers, industrial operators, and organizations supervising multiple tanks, Four Data has created the Four Data Academy—a dedicated training program designed to help your teams become fully autonomous with connected tank gauge management.

A Four Data expert comes directly to your facilities to deliver hands-on training, including:

-

installation best practices for multi-tank setups,

-

platform configuration and real-time tank monitoring,

-

consumption reporting and alert management,

-

optimization of filling schedules and supply chains,

-

maintenance and troubleshooting procedures,

-

integration with ERP and operational workflows.

This professional training ensures your team gains the skills needed to operate, analyze, and optimize your entire tank fleet, boosting operational efficiency and reducing downtime.

The Four Data Academy helps businesses achieve:

-

full internal autonomy,

-

improved stock visibility,

-

smarter planning of refills,

-

reduced logistics costs,

-

higher environmental performance.

Why install a connected tank gauge before winter?

-

avoid heating breakdowns

-

anticipate deliveries

-

control heating expenses

-

reduce energy consumption

-

improve environmental efficiency

-

secure your installation

-

save time every day

Conclusion

The connected tank gauge is the most reliable way to prepare for winter. Thanks to remote monitoring, IoT technology, and simple installation, you can avoid breakdowns, optimize deliveries, and reduce costs.

👉 Four Data provides a scalable, precise, and reliable solution for all tank types.

You may also be interested in these articles :