How do connected platforms improve customer relations in gas and fuel distribution?

Summary

- Digitalization at the service of energy customers

- IoT platforms for performance and customer satisfaction

- A new customer experience thanks to connected platforms

- Four Data: the agnostic platform at the heart of customer performance

- The concrete benefits of digitalization in energy distribution

- FAQs

- Connecting data to bring customers closer together

In the oil and gas sector sector, distributors must meet higher customer expectations: transparency, responsiveness and better service. better service. Visit digitalization is profoundly transforming fuel distributiondriven by the rise of connected platformsplatforms, intelligent sensors and IoT connectivity. Thanks to these digital solutions, companies gain in operational efficiencyvisibility and reliability, while controlling their carbon footprint. This evolution is revolutionizing customer relations, paving the way for a more automated, personalized and sustainable model.

Digitalization at the service of energy customers

The new face of energy distribution

The gas distribution and fuel is evolving under the pressure of a more demanding market. Customers, whether industrialists, transporters or players in the oil and gas sectornow expect better servicemore transparent and permanently available. Operators must therefore guarantee a reliable supply, limit the number of deadlinesanticipate needs and manage sometimes outdated infrastructures old. In the face of these challenges digital transformation is essential: automation of repetitive tasks, management management tools online management tools, greater visibility of resources, and the integration of intelligent objects that enable better, faster decision-making.

A transformation driven by connected platforms

The connected platforms are profoundly transforming distributors’ businesses. Thanks to IoT connectivityconnectivity connected sensors and real-time monitoringevery tank, meter or service station becomes a source ofinformation exploitable. The data collected improves the operational efficiencyoptimize truck routing, streamline planning and planningreduce costs and contribute to emissions.. This digital implementation is fully in line with the energy transitionwhile strengthening customer relations with faster response times and total transparency.

IoT platforms for performance and customer satisfaction

Intelligent inventory and delivery management

In the gas distribution and fuel distributiontank level accuracy is essential to ensure a constant supply of supply reliable. Thanks to level sensors and real-time monitoring systemsWith this system, distributors have immediate visibility of each site: tank status, remaining volumes, risk of breakage. Combined with predictive planningThe connected platform optimizes truck routes, reduces mileage and cuts logistics costs. Automated replenishment ensures a constant supply of goods. service and improved customer satisfactioneven in a context of fluctuating prices and variable demand.

Proactive maintenance and enhanced reliability

The integration of connected sensors in stations and depots enables upstream detection of anomalies: abnormal variations, risks of leakage leaksunstable pressures or equipment faults. By cross-referencing sensor data with incident history, companies in the oil and gas sector improve their operating efficiency and anticipate technical interventions. This approach reduces unplanned stoppages, makes installations safer and helps to limit the impact on the environment. carbon related to unplanned travel.

Logistics synchronization and ecoperformance

By connecting all equipment – tanks, service stations, trucks – the IoT platform ensures smooth coordination of every operation. L’automation repetitive tasks (planning, notifications, delivery orders, etc.) delivery orders) can reduce costsminimize unnecessary journeys and reduce greenhouse gas emissions. Follow-up in real-time helps operators optimize routes, make better use of resources and enhance safety.

Support and loyalty: proactive customer relations

Connected platforms also improve relationship management client. Thanks to integrations with CRM software and digital tools, our teams have access to a full range of information: order history, levels consumed, personalized alerts and the status of the equipment fleet. This level of information makes it possible to offer a best servicemore responsive and totally transparent. Customers benefit from an online portal where they can consult their data, track their orders and view their consumption in complete autonomy.

A new customer experience thanks to connected platforms

Customization and on-demand services

Connected platforms enable gas distributors to gas and fuel distributors offer more personalized services, in line with the expectations of a rapidly digitalizing market. Thanks to the data collected in real timeEach company can offer customized options: delivery applicationThese include intelligent alerts when reservoir levels drop, and customer portals that allow them to view their consumption. This approach improves customer experiencestrengthens relationships and helps anticipate demand without overloading operational teams.

Smooth communication and integrated support

Integration between the IoT platform and CRM software (Salesforce, ServiceNow or other digital solutions on the market) is transforming the way teams follow up and support their customers. Information linked to networkThis means response times are reduced, and errors from legacy systems are eliminated. Assistance becomes automatedfaster and better aligned with the challenges of the oil and gas sectorwhere every minute of delay can impact operations and satisfaction.

Transparency and measurable satisfaction

Connected platforms provide customers with unprecedented visibility: dashboardsThis transparency strengthens trust and encourages long-term collaboration between supplier and end-user. This transparency builds trust and fosters lasting collaboration between supplier and end customer. By making information instantly accessible, distributors demonstrate their reliability, while reinforcing their ability to reduce costsoptimize operations and respond faster to market fluctuations.

Four Data: the agnostic platform at the heart of customer performance

A platform compatible with all your sensors

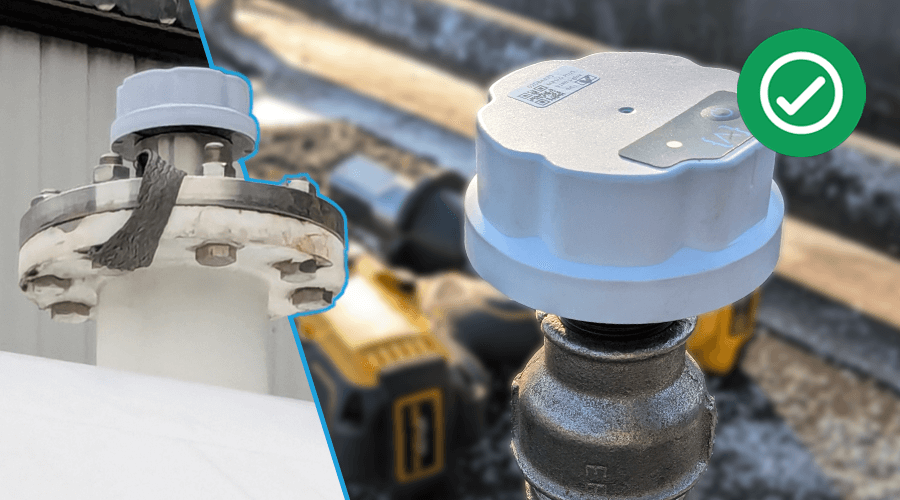

Our platform has been designed to adapt to the realities of the oil and gas sectorThis is where new sensors, older devices and equipment from multiple suppliers often coexist. Thanks to a truly agnosticFour Data easily integrates any device already deployed on your sites: meters, sensors, tanks, smart objects or proprietary systems. This compatibility guarantees implementation without replacing your existing infrastructure, reducing costs and accelerating return on investment. You keep your existing infrastructure, while benefiting from the power of a single platform. connectedscalable and reliable.

Open, interoperable IoT architecture

Four Data is based on an open infrastructure, capable of working with all major networks IoT networks on the market: Sigfox, LoRa, NB-IoTLTE-M or conventional cellular networks. This interoperability ensures IoT connectivity in real time, even in remote areas or harsh environments. Data is transmitted via a secure system, compliant with European best practice, to protect your critical installations and limit any operational risk. This flexibility enables energy distributors to unify all their sites, trucks and service stations within a single digital environment.

A unified user experience

Beyond technology, Four Data offers a unified experience designed for business users: clear dashboards, intelligent alerts, automatic reports, multi-site monitoring and complete activity supervision. Every employee, whether operator, logistics operator, quality manager or general managerThe platform becomes a central tool for the company. The platform becomes a central tool for optimize managementreduce inefficiencies and strengthen customer customer relations thanks to reliable, accessible information.

The concrete benefits of digitalization in energy distribution

Lower operating costs

Digitization enables gas distributors to gas and fuel distributors to streamline their operations throughlogistics automation and intelligent tools capable of synchronizing every stage of the chain: ordering, routing, replenishment and field follow-up. By reducing manual intervention and unnecessary travel, companies cut costs while improving their efficiency. operational efficiency. Teams save time, better manage resources and limit the risk of errors associated with old processes.

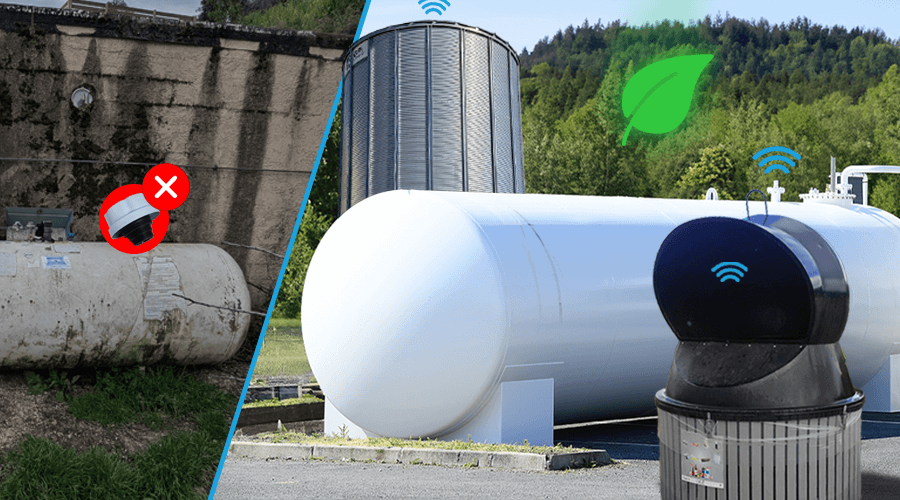

Sustainable management and environmental compliance

By optimizing routes, energy consumption and equipment use, connected platforms make a direct contribution to reducing greenhouse gas emissions. This more environmentally-friendly management approach meets market expectations, but also the growing demands of the European Commission. Thanks to better visibility of tank levels and plant status, distributors can reduce their costs. carbon footprintand optimize their use of resources on a global scale. global level.

A long-lasting, personalized customer relationship

Digitization helps strengthen customer relationships customer relations with tools that improve transparency, communication and monitoring. Automatic dashboards and reports provide easy access to information. information in real time, while personalized alerts and detailed knowledge of consumption strengthen customer loyalty. Teams can anticipate needs, offer a more efficient better service and develop more personalized support.

FAQs

Connecting data to bring customers closer together

From operational performance to customer satisfaction

The digital transformation at oil and gas sector paves the way for smarter, more sustainable and more profitable management. By centralizing data and automating operations connected platforms reduce inefficiencies, enhance safety and improve customer satisfaction over the long term. customer satisfaction. They accompany the energy transitionwhile helping companies to control their costs, their carbon footprint and overall performance.

Four Data, a partner in digital energy transformation

Thanks to our IoT expertise and agnostic agnostic platformagnostic platform, we help energy distributors modernize their infrastructures, optimize their operations and deliver better service to their customers. Whether you’re looking to boost your visibility, automate your logistics or improve your customer relations, Four Data can help you from the outset. implementation to field deployment.

You may also be interested in these articles :