Installation of a connected gauge: a complete guide to successful installation

Summary

- Connected gauge: definition and operation

- Why install a connected gauge?

- Compatibility: does your tank fit?

- How to choose the right connected gauge?

- Installing a connected gauge: essential steps

- Common problems and quick solutions

- Installing a connected gauge with Four Data

- FAQ – Installation of a connected gauge

- Switch to remote monitoring today

Monitor oil level of fuel oilwater or any other liquid has become an essential factor in avoiding breakdowns. breakdownoptimize consumption and secure your tank. Thanks to the IoT, theinstallation of a connected gauge offers a smart intelligent solutioncapable of measuring fill level in real time and send an alert from a distance. In this guide, we’ll help you understand how a level gaugehow to install it easily and why Four Data offers a complete approach combining level sensordigital platform and expert advice.

Connected gauge: definition and operation

What is the purpose of a connected gauge?

A connected gauge provides precise filling level a tank of oilfuel oil, water or any other liquid, directly from a mobile application. Thanks to the remote monitoringprovides a real-time real time of remaining volume, helping to avoid stock-outs, optimize consumption and schedule free delivery or replenishment.

Its main benefits:

- Follow the level at any time

- Receive an alert as soon as a critical is reached

- Anticipate energy needs and avoid unforeseen events

- Improving resource management for domestic, agricultural and industrial use

How does an intelligent level sensor work?

A level sensor uses a technology (ultrasound, pressure or radar) to measure the volume present in the tank. The data is then transmitted via a IoT network to a platform that provides tracking tracking fill rate.

Simplified operation :

Measurement → Transmission → Analysis → Application

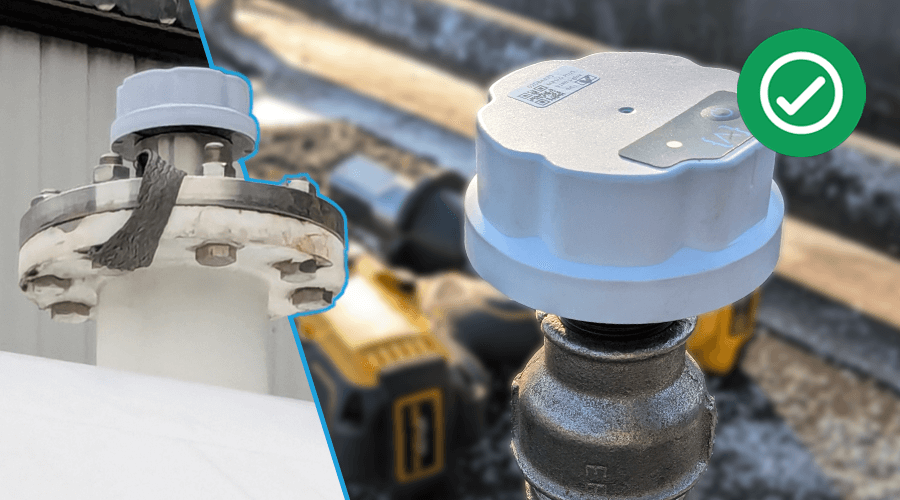

Before / after :

- Before: manual, imprecise, float-dependent reading.

- After: automatic measurement, real time, notifications and online history.

Myth vs. reality

Reality: a connected probe consumes any Wi-Fi in the tank – it uses a dedicated low-speed network.

Transmission technologies: LoRaWAN, Sigfox, NB-IoT, LTE-M

Visit connected fuel gauges are based on several long-range IoT networks. Our approach is agnostic we choose the best network depending on the tank, location and reception conditions.

| Technology | Range | Operating time | Typical uses |

|---|---|---|---|

| LoRaWAN | Very long | Excellent | Rural areas, outdoor tanks |

| Sigfox network | Long | Very long | Simple tracking, low power consumption |

| NB-IoT | Very good | Good | Industrial sites, dense areas |

| LTE-M | Very good | Good | Mobility, harsh conditions |

Why install a connected gauge?

Remote level monitoring and automatic alerts

Install a connected gauge to know the filling level a tank remotelydirectly from an application. You receive notifications as soon as a threshold is reached, making it easier to anticipate and avoid any interruption ofenergy.

Immediate benefits :

- Continuous level

- Alert in the event of an abnormal drop

- Ordering heating oil at the right time

- Simplified management of your consumption

Example alert: “Your tank has reached 18%. Think about order your fuel oil.”

Case study

In Belgium, a private individual avoided a winter blackout thanks to an alert received on a Sunday morning.

Preventing breakdowns and optimizing consumption

By precisely monitoring the remaining volume, the level gauge helps avoid breakdowns and understand how consumption consumption over the months. The user benefits from a clear vision that allows him to optimize his budget and his planning. delivery.

Securing tanks (theft, leaks, human error)

A connected probe can also be used to detect abnormal behavior: a rapid drop in level (leakage), unauthorized sampling or a filling error.

Advantages :

- Reservoir tank

- Alert in case of abnormal variation

- Secure storage and fuel

Compatibility: does your tank fit?

Compatible tanks: fuel oil, GNR, diesel, water, IBC

The connected gauges are designed to operate over a wide wide range of vessels and tanks, whatever the liquid or model used. They accurately measure level d’water levelof heating oilof dieselof GNR or similar fuels.

Concrete examples:

- Cylindrical tanks in plastic or metal

- Underground tanks

- Rectangular IBC tanks

- Small tanks for heating or energy storageenergy storage

Compatible formats :

| Tank type | Material | Application |

|---|---|---|

| Fuel oil | Steel / HDPE | Domestic heating |

| GNR / diesel | Metal / polyethylene | Agricultural / industrial |

| Water | Plastic | Watering/reserve |

| IBC 1000 L | Plastic | Versatile storage |

Specific case of Belgium: fuel oil tanks

In Belgium, a large proportion of homes still run on heating oil. heating oilThese plants are often old, with tanks that are sometimes old or heterogeneous in size and shape. Modernizing these facilities is essential to ensure remote monitoring and anticipate consumption.

To find out more, visit our page dedicated to the connected oil gauge.

Check dimensions, hatches, materials and network coverage

Beforeinstall gauge, it is essential to check a few technical parameters: internal height, trap diameter, type of liquid, compatibility of the fuel sensoror the network coverage around the tank.

Thanks to our expertise, we can help every customer validate the configuration and choose the solution solution.

Quick checklist

- Internal tank height

- Hatch size

- Adapter type screw

- Availability of Sigfox, LoRaWAN or cellular network

How to choose the right connected gauge?

Available sensors: ultrasonic, pressure, radar

Depending on the type of liquid, vessel shape and operating conditionsdifferent sensors can be used to measure level.

| Technology | Benefits | Contexts of use |

|---|---|---|

| Ultrasonic | No liquid intrusion | Fuel oil, RNG, water, domestic tanks |

| Pressure | Highly accurate at great heights | Industrial tanks, diesel, underground storage |

| Radar | Resistant to vapors and variations | Harsh environments, agriculture, chemicals |

They are all connecteddesigned to transmit data and provide reliable measurement of volume.

Key technical criteria: autonomy, precision, waterproofing

To choose a fuel gaugeit is essential to consider the following parameters:

- Battery life several years for maintenance-free monitoring

- Measurement accuracy essential for optimizing consumption

- Waterproof resistant to splashes, dust and temperature variations

- Network compatibility quality of network coverage depending on location

- Service life: fuel cell robustness over the long term

Adapters and fittings according to tank type

According to the model different adapters are available for attach the gauge: 2″ adapter, IBC plug, threaded reducer or magnetic support.

Mini-list :

- Screw-on adapters screw-on

- Fittings for IBC tanks

- Clamps for metal tanks

Installing a connected gauge: essential steps

Preparing the tank and ensuring safety

Before installing a connected gaugeIt is essential to secure the area and check that the tank is accessible and clean. If you use heating oilremember to switch off the boiler to avoid any aspiration during the work.

Preparation checklist :

- Check theaccess to hatch

- Lightly clean all around

- Switch off oil boiler

- Prepare adapter or screw cap

Position and secure the gauge correctly

The gauge must be placed vertically, centred in relation to the volume. volume without touching the liquid or the inner walls.

Mistakes to avoid:

- Installing too close to the edge

- Place the gauge over an indentation

- Improperly tighten the adapter, creating an air gap

Connect the device to the application or platform

Once attached, the gauge connects to themobile application or to the Four Data platform.

Steps :

- Switch on level sensor

- Associate the device via the dedicated space

- Enter liquid type and tank

- Check network connection

Calibration and verification of first measurements

Calibration provides a measurement reliable fill level from the very first day.

Key steps :

- Indicate tank height

- Define the liquid (fuel oil, water, diesel…)

- Check the first reading in real time

Common problems and quick solutions

Poor positioning or obstruction

Incorrect positioning can distort the measurement or prevent the level sensor to function properly. The most common causes :

- Gauge installed too close to the edge

- Internal reinforcement

- Obstruction by float or deposits

Solution: reposition the gauge in the center of the hatch and check that nothing interferes with the measurement zone.

No network or poor connectivity

Some areas may lack network coveragenetwork coverage, preventing real time.

Advice :

- Test the area around the tank beforeinstallation

- Check compatibility with LoRaWAN, LTE-M, NB-IoT or Sigfox network

- Use Four Data analysis to identify the best option for each site

Thanks to our network-agnostic approachwe select the most reliable technology for each tank.

Calibration errors or mechanical incompatibility

Incorrect height, incorrect hatch diameter or unsuitable adapters can interfere with the measurement. measurement.

Solutions :

- Recheck internal height

- Check tank type and shape tank

- Use the adapter recommended by the manufacturer

Professional recommendation: have the configuration validated by an expert when the volume exceeds 2,500 L or in the case of non-standard tanks.

Common errors

- Install without checking headroom

- Choose a sensor that is not compatible with the liquid

- Forgetting the initial calibration

Troubleshooting checklist

- Is the gauge centered?

- Is the network available?

- Is the height correct?

- Is the adapter securely attached?

Installing a connected gauge with Four Data

Our IoT expertise: sensors + management platform

At Four Data, we master the entire IoT chain: hardware, software and network. We offer a connected gauge a reliable fuel sensor sensor and an intuitive platform for monitoring filling level remotely.

🔧 sensor design and selection

💻 data analysis and supervision

📡 choosing the best protocol for the site

Comprehensive support: selection, installation, follow-up

Our team accompanies each customer from the definition of the requirements through to commissioning, using a tried-and-tested 5 steps :

- Understanding the context and the liquid used

- Choose the intelligent sensor adapted

- Check network network coverage

- Assist withsimple installation and configuration

- Daily monitoring and analysis

This support guarantees a durable, accurate solution optimized for real-life use.

Applications: private individuals, farmers, industry, multi-tank fleets

Individuals

Remote oil level oil levelalerts and heating optimization assistance.

Farmers

Fuel fuel (RNG, diesel), stock management and anticipation of seasonal needs.

Industries

Efficient management of multiple reservoirs and reduced risk of rupture.

Multi-tank fleets

Data centralization, management and improved delivery planning delivery.

FAQ – Installation of a connected gauge

Switch to remote monitoring today

Install a connected gauge is one of the most reliable reliable, simple and sustainable for monitoring fill level of a tank and avoid incidents. Whether you’re a private individual, a farmer or a manufacturer, Four Data can help you choose the right fuel sensor ensure accurate installation and set up real-time real-time monitoring.

👉 Need help or personalized advice? Contact our experts and find out how Four Data can secure and optimize your fuel oil management.

You may also be interested in these articles :