Connected gauges: benefits for local authorities and professionals

Summary

Managing fuel or heating tanks is a major operational challenge for local authorities. local authorities and multi-site professionals. Between budget constraints, safety requirements and service continuity, manual monitoring quickly shows its limits. Visit connected gauge provides a concrete response by offering a centralized, remote view of levels, facilitating decision-making and optimizing operations. By leveraging IoT technologies, it becomes possible to move from reactive management to more reliable, more secure and better controlled management.

Challenges in the field for local authorities and professionals

Tank management: scattered sites and operational constraints

Local authorities and professionals often have to manage tanks spread over several buildings. buildingswarehouses or technical equipment. This scattered sites complicates level monitoring and multiplies logistical logistics The key to success: variable access, prioritization of interventions, team coordination. Without a global vision, it becomes difficult to anticipate real needs and optimize day-to-day operations.

Limits of manual monitoring and estimates

- Time-consuming and unreliable manual readings

- Unnecessary trips to check levels

- Risk ofhuman error when taking readings

- Nohistory to analyze consumption

- Decisions made without consolidated data

Why is data becoming a steering lever for public and private players?

Remote access to data transforms tank management. By centralizing information on a single platform, teams have access to a complete consolidated vision and can make faster, more relevant decisions. Data thus becomes a genuine decision supportfor operational performance.

Multi-tank and multi-site management: centralized control

Centralize level monitoring on a single dashboard

Multi-tank management becomes more efficient when all levels are grouped together on a single single dashboard. This centralized system enables teams to see the status of each tank at a glance, identify priorities and track changes over time. Data is updated automatically, providing reliable, usable information without manual intervention.

Supervision of dispersed sites: buildings, depots, equipment

For local authorities and companies with geographically geographically dispersed sitesRemote supervision simplifies control considerably. Whether public buildings, technical depots or isolated equipment, each site can be monitored from a single interface. This approach reduces organizational complexity and improves coordination between field teams and operations managers.

Applications: schools, sports facilities, municipal buildings, industrial sites

Case study A local authority manages several schools and sports facilities equipped with tanks. Thanks to centralized monitoring, the technical department can view levels remotely, anticipate needs and plan deliveries without any urgency. The result: fewer journeys, better service continuity and smoother management of energy resources.

Benefits for technical departments and operations managers

- Time-saving in daily monitoring

- Prioritization of interventions based on reliable data

- Better coordination between field teams and decision-makers

Operational optimization and measurable savings

Anticipate needs and put an end to unnecessary rounds

Precise, continuous monitoring of levels enables us toanticipate real needs and avoid systematic inspection rounds. Teams intervene only when necessary, based on reliable data rather than routine checks. This approach rationalizes travel and improves overall efficiency.

Optimization of delivery and maintenance routes

With consolidated visibility of all tanks, delivery routes can be delivery and maintenance can be planned more coherently. Interventions are grouped together, priorities clearly identified, and emergencies limited. This organization reduces operational pressure and improves service quality.

Reduce costs: time, fuel, human resources

- Less unnecessary travel

- Reduced time spent on controls

- Optimizing team assignment

- Lower fuel and logistics costs

Short- and long-term economic benefits

| Cost item | Observed impact |

|---|---|

| Travel | Significant reduction |

| Working time | Better productivity |

| Emergencies | Sharp decrease |

| Logistics | Better planning |

Security and service continuity

Automatic alerts: critical level, leak, abnormal consumption

Connected gauge systems trigger automatic automatic alerts as soon as a critical threshold is reached or unusual behavior is detected. These notifications enable teams to intervene quickly, before a situation becomes problematic, and to take targeted action without waiting for a field check.

Preventing theft and undetected losses

An abnormal variation in level may indicate theft or unidentified loss. Continuous monitoring makes it easier to detect these deviations and react quickly, while reinforcing surveillance of the most exposed installations.

Securing sensitive installations

Public buildings, technical sites and critical infrastructures require a high level of security. Remote monitoring helps protect these facilities by reducing the risk of incidents and improving the responsiveness of teams to high-risk situations.

Continuity of service for public and professional buildings

Continuous monitoring ensures continuity of serviceThis is particularly true for essential equipment such as heating systems. By anticipating critical situations, managers can avoid unforeseen interruptions.

A connected gauge integrated into a global IoT project

Sensors, networks and supervision platform

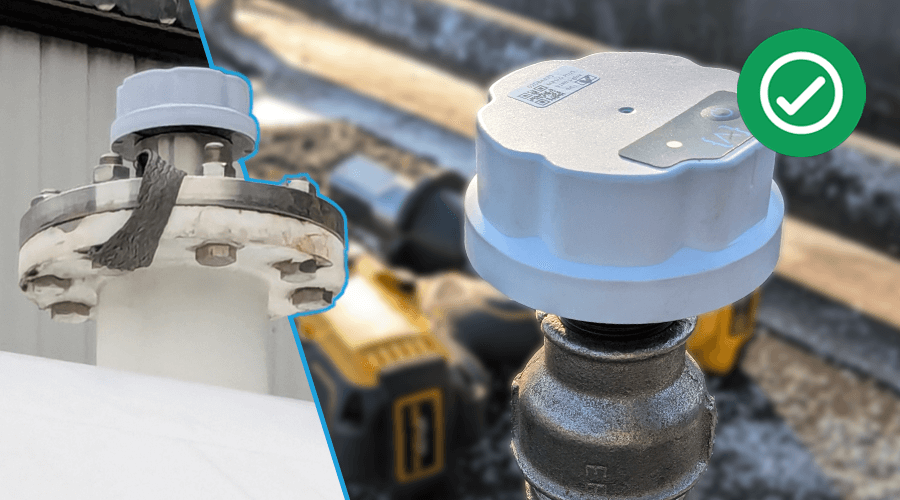

A connected gauge relies on a coherent set of sensorssensors communication networks and a supervision platform platform. Sensors collect data in the field, IoT networks transmit it securely, and the platform delivers usable information to operational teams.

Data processing for maintenance and decision-making

Beyond simple measurement, the data collected becomes a tool for management tool. They enable us to anticipate maintenance needs, identify usage trends and base operational decisions on reliable indicators rather than assumptions.

Four Data support: from pilot to deployment

At Four Data, we support local authorities and professionals every step of the way: understanding their needs, pilot phase, gradual deployment and ramp-up. Our approach guarantees a solution adapted to local constraints and integrated into the existing ecosystem.

To go further, discover our dedicated solution for connected oil gaugedesigned for easy integration into IoT projects at site or multi-site level.

FAQ – Connected gauges for municipalities and professionals

You may also be interested in these articles :