From mobile tank to connected depot: IoT use cases in the Oil & Gas sector

In a sector where every liter of fuel counts, the and tank management represents a major challenge for operators Oil & Gas. The transition from mobile tank to the connected tank transforms the way in which levels are monitored, supplies anticipated and operations optimized. Thanks to IoTmanagers now have a connected connected solution that centralizes data in real-time and guarantees sustainable of management of gas, fuel or oil stocks. A strategic shift towards storage facilities safer, smarter and more efficient.

Challenges and transformation in the Oil & Gas sector

The sector Oil & Gas sector is faced with a dual challenge: ensure continuity of supply while while reducing operating costs and risks related to the storage of energy products. In the field, the growing number of websites and mobile tanks complicates inventory managementoften carried out manually or using heterogeneous tools. These methods slow down decision-making, increase the cost of transport and weaken safety operations.

The limits of traditional tank and depot management

On many farms, monitoring monitoring levels still relies on visual checks or paper reports. The result: frequent errors, excessively long response times and a reduced logistics efficiency. Without precise measurements, it is difficult toanticipate needs, d’avoid overflow oroptimize deliveries.

The rise of connectivity in industry: the contribution of the IoT

L’IoT brings a major breakthrough: connected connected sensors measure fuel level continuously and transmit the data to a centralized platform. This information, available in real-timeoffer managers complete visibility for plan, monitor and manage remotely their storage facilities.

Strategic benefits for Oil & Gas players

- Secure operations and early detection of anomalies.

- Reduce logistics costs and unnecessary interventions.

- Enhanced regulatory and environmental compliance.

- Global control of several tanks connected to a single control panel.

IoT use cases: from mobile tanks to connected warehouses

The applications of theIoT applications in the Oil & Gas sector cover the entire supply chain, from the mobile tank to the connected connected depot. Every sensor, every connected gauge and each management platform contribute to a global view of inventory, guaranteeing precise precise trackingand optimal planning and reduce operational risks.

Level monitoring and automated replenishment

The connected sensors continuously measure fuel level and transmit the data to the IoT platform. When the defined threshold is reached, a automatic alert triggers the replenishment order, avoiding any downtime downtime.

Geolocation of site tanks and tracking of movements

The mobile tankers equipped with a GPS module allow you to know their exact position, their route and the downtime at each site. Logistics managers can monitor their equipment and avoid material losses.

Safety and compliance thanks to connected gauges

The level sensors detect any anomaly: unauthorized opening, leakage, or abnormal pressure variation. These alerts ensure storage safety and regulatory compliance.

Multi-site management and centralized depot supervision

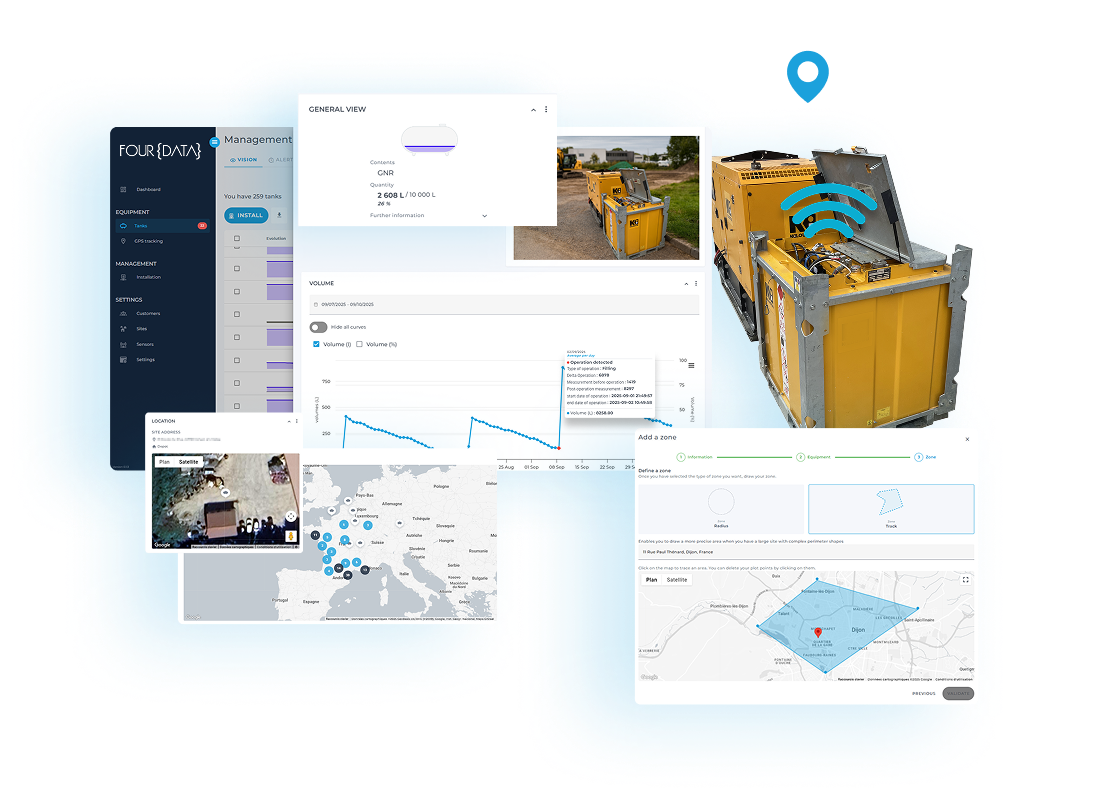

Thanks to the Four Dataweb-based managers visualize at a glance the levels of all their connected connected tankswhether fixed or mobile. This overall supervision facilitates logistics planning and inventory management across several depots or service stations.

Technologies and architecture of an Oil & Gas IoT solution

The performance of a connected IoT solution is based on a coherent set of components : sensors, networks, software platform and security infrastructure. Together, they form a complete IoT system capable of transforming field data into usable information, accessible at any time via the web or a mobile application.

Smart sensors and gauges: how do they work?

The connected sensors installed on storage tanks continuously measure the fuel level or fluid. The values are then automatically transmitted to the supervision platform. Each model is selected according to liquid type, tank size and operating environment.

Communication networks and protocols (LoRa, Sigfox, NB-IoT, LTE-M…)

The choice of IoT network network determines the performance and reliability of data transmission from connected sensors. Each technology has features tailored to a specific environment: isolated areas, temporary worksites, fixed or mobile warehouses, etc. portable tanks.

| Network | Medium range | Energy consumption | Data rate | Typical use case | Coverage in France |

|---|---|---|---|---|---|

| LoRa | Up to 15 km | Very low | Low | Isolated sites, rural areas | Very good |

| Sigfox | 10-40 km | Very low | Very low | Long-term monitoring of mobile tanks | Excellent |

| NB-IoT | 5-10 km | Low | Medium | Fixed depots, enclosed buildings | Expanding |

| LTE-M | 2-5 km | Average | High | Fast transmission to connected service stations or depots | Very good |

👉 This comparison helps managers choose the optimal network depending on the type ofstorage facility and the signal availability. In practice, Four Data offers solutions multi-network capable of automatically switching to the best available connectivity.

Management platform: real-time visualization, alerts and control

The data collected is centralized in the Four Data platformaccessible from any connected device. Users can consult levelsconfigure automatic automatic alertsalerts, analyze trends and manage its entire fleet of connected tanks.

Safety, reliability and integration with existing systems

All information is hosted on secure servers serverswith encryption and redundant backup. The solution integrates easily with existing management (ERP, maintenance, supervision).

Benefits and customer feedback

Implementing an IoT solution solution transforms fuel storage and connected connected tanks into a measurable performance driver. Customer feedback shows a clear improvement in profitabilityand safety and environmental management.

| Indicator | Before IoT | After IoT Four Data |

|---|---|---|

| Tank level monitoring | Manual, irregular readings | Automated, real-time data |

| Logistics tours | Fixed planning | Optimization according to actual level |

| Risk of breakage | High | Automatic prediction and warning |

| Delivery traceability | Partial | Complete and centralized |

| Carbon impact | Not measured | Up to 25% reduction |

Reduce logistics costs and optimize routes

Thanks to precise fuel level monitoringfuel managers plan only the deliveries necessary deliverieseliminating empty runs. This approach reduces logistics costs andcarbon footprint.

Breakage prevention and better planning

Visit automatic alerts from connected sensors anticipate each and every supply. Visit manager receives notification as soon as a critical threshold is reached, ensuring business continuity and uninterrupted uninterrupted service.

Environmental compliance and fuel traceability

The data collected guarantees complete traceability volumes, supporting regulatory compliance and sustainable management resources. This transparency facilitates audits and enhances the value of CSR initiatives.

Oil & Gas customer case studies

Case study :

A fuel distribution company in France connected 300 tanks with the Four Data solution. In less than a year, it saw a 28% reduction in unnecessary travel and an average 18% saving on logistics costs, while improving site safety.

Implementing an IoT solution with Four Data

At Four Datawe support players in the Oil & Gas sector in the implementing complete IoT solutionssolutions to improve the management of connected tankstanks mobile tanks and storage depots. From the design phase to industrial deployment, our approach guarantees seamless, sustainable integration adapted to each environment.

Our methodology: from audit to industrialization

Each project begins with a technical audit your existing equipment and business needs. Our team then designs a Proof of Concept (POC) before large-scale deployment.

A complete hardware + software offering

We design and integrate connected sensors sensors combined with a software platform platform for global, centralized monitoring of your fuel inventories.

ALOREM exclusive OEM partnership

Four Data and ALOREM join forces to offer an OEM solution dedicated to mobile tanks. This joint offering enables tanks to be fitted directly at the factory, guaranteeing native connectivity and simplified installation.

👉 Discover the offer : ALOREM x FOUR DATA – OEM for mobile tanks

Our oil & gas sector expertise

Our experience terrain and the constraints associated with energy products enables us to adapt the connectivityand protocols and sensors depending on the environment.

Guidance, support and operational follow-up

Our teams provide follow-up preventive maintenance, technical support and software upgrades. Customers benefit from dedicated support and direct direct help via the Four Data web platform.

To find out more about our industry-specific solutions, visit our oil & gas.

FAQs

Towards the future of connected Oil & Gas

The coming years will mark a new era new era for the Oil & Gas sectordriven byautomation andpredictive analysis. Connected solutions will evolve towards more flexible systems. intelligentcapable ofanticipate needs and optimizeenergy efficiency.

Predictive maintenance and digital twins

Thanks to digital twinseach connected tank can be modeled virtually. This simulation makes it possible to anticipate component wear, adjust interventions and extend the service life of the components. service life of installations.

Artificial intelligence and energy optimization

L’AI will analyze the data collected to fine-tune energy consumptionadjust automatic automatic supplies and reduce operating costs. It will become a true co-pilot for managers.

Towards a more sustainable transition thanks to data

The data is becoming a driving force energy transition. L’IoT contributes to sustainable of fuel by limiting losses and emissions.

You may also be interested in these articles :