Connected gauge for biofuels monitor your levels remotely, avoid breakdowns

A connected gauge is an intelligent sensor installed on a tank or reservoir, enabling remote measurement of the fuel leveland optimize fuel storage storage and refueling operations.

In a context of energy transition, biofuels biofuels such as HVO100 or B100 play a key role. To maximize their environmental impact, it is essential to secure their availability andand avoid disruptions.

Our solution offers automated managementmanagement personalized alerts and a real-time visibility for smoother, greener and more profitable logistics.

Why adopt a connected gauge for your biofuel tanks?

Optimize inventory management and avoid stock-outs

The use of a connected gauge on a biofuel tank enables eVMI (Electronic Vendor Managed Inventory) management, transforming a simple tank into an intelligent intelligent monitoring system. The benefits are immediate:

- Continuous fuel level monitoring in each tank, without physical displacement or approximation.

- Customizable automatic alerts according to defined critical thresholds (e.g. < 30% of volume), allowing you to anticipate replenishment before stock-outs occur.

- Reduced risk of running out of fuelwhich can lead to loss of business or immobilize a fleet.

- Remote visibility for professionals managing several geographically dispersed tanks.

- Case in point: a service station dispensing HVO100 can avoid unscheduled shutdowns thanks to accurate and frequent data feedback.

This connected approach is part of a drive for reliability, automation and a reduction in emergency interventions, while ensuring business continuity.

Reduce logistics costs and improve planning

By connecting your tanks to a tracking platform, delivery planning becomes data-driven routes are optimized according to actual needs.

- Fewer unnecessary journeysless fuel, less wear and tear on vehicles and less time spent on the road.

- Intelligent grouping of deliveries based on actual stock levels, not estimates.

- Direct improvement in carbon footprint:

– Up to -18% reduction in kilometers traveled

– That’s -12% CO₂ per ton delivered

– With an ROI < 9 months on equipment and installation.

These figures show that the connected gauge is not just a tracking tool, but a logistics logistics performance solution solution for companies.

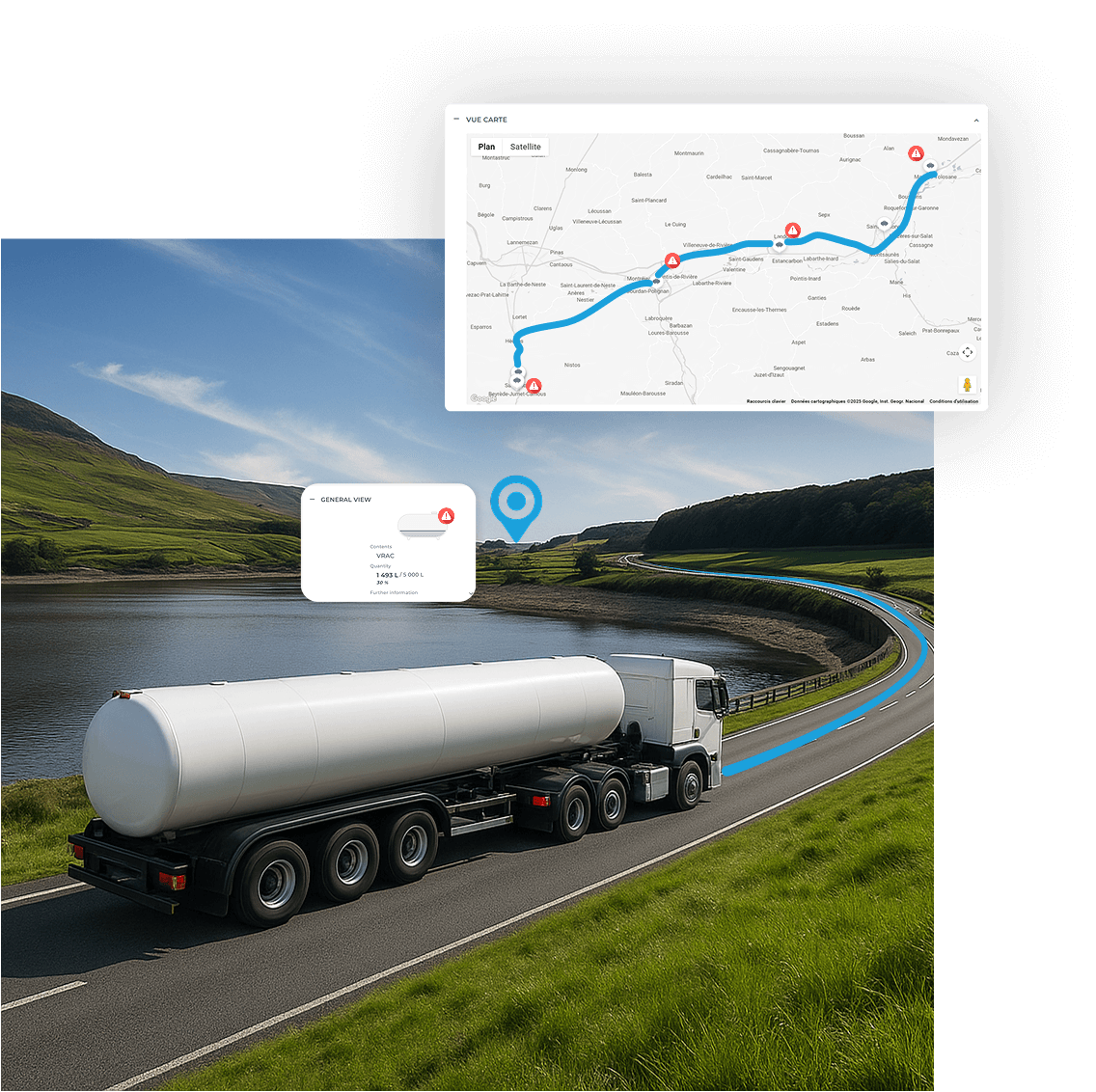

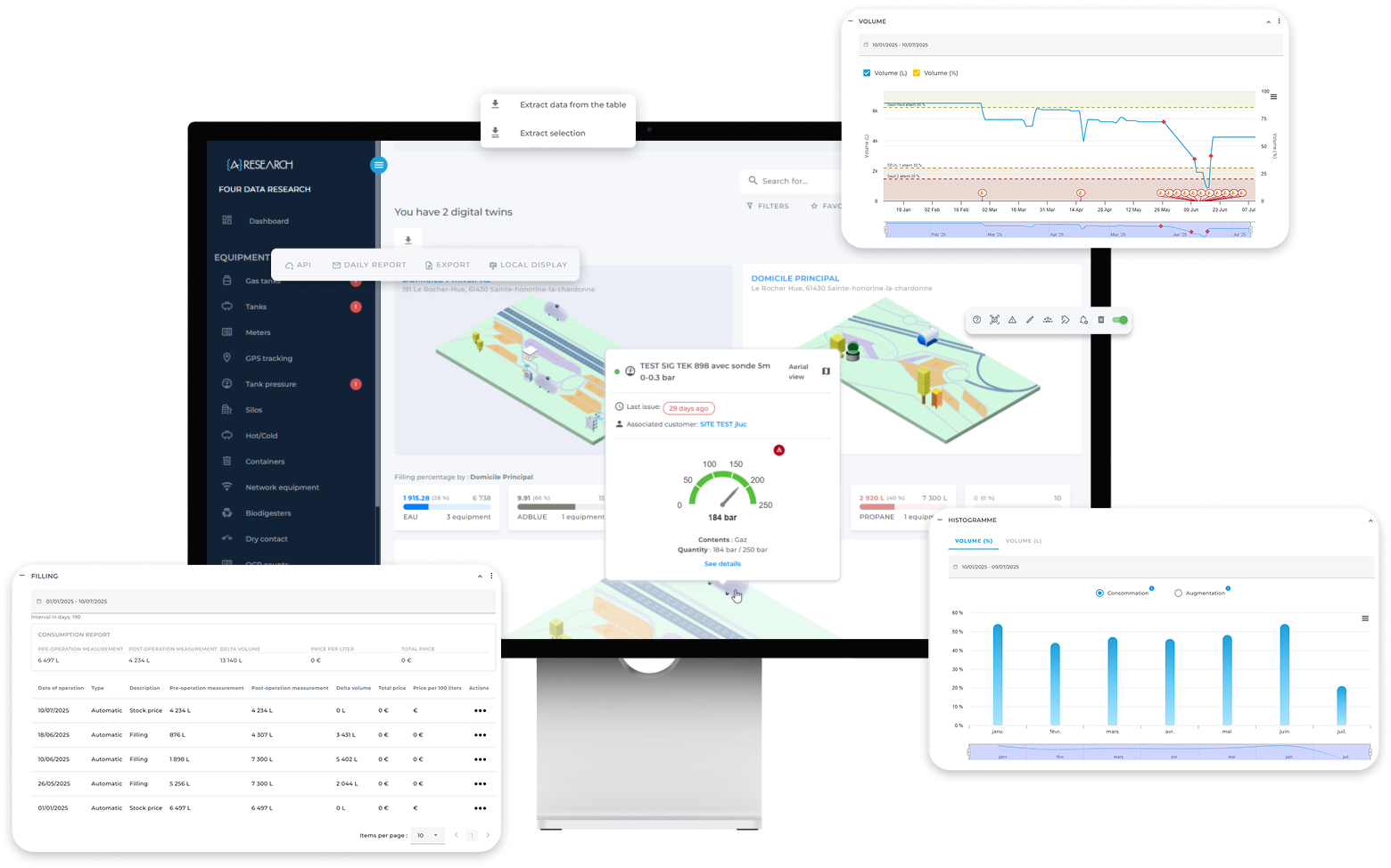

Remote monitoring

Thanks to integrated connectivity (NB-IoT, LTE-M), each sensor installed on a tank automatically sends its data to a secure web interfaceaccessible from a computer or smartphone.

- Real-time visualization of the level of each tank, regardless of its location.

- Intuitive dashboardsCustomizable filters (by site, by fuel type, by threshold).

- Multi-user accessibility for logistics, purchasing or maintenance teams.

- Secure data hosting, with traceability of consumption.

Who is our connected gauge for?

Our connected biofuel gauge meets specific and differentiated specific needs by business sector. Here’s an overview of use cases and associated benefits for each customer profile.

Alternative fuel distributors and service stations

- Typical use case :

Centralized monitoring of several tanks (HVO100, B100, Oleo100…), optimization of refueling rounds. - Specific needs :

➤ Maintain distribution continuity,

➤ Reduce empty or emergency deliveries,

➤ Remotely visualize levels for multiple sites. - Added value :

→ Anticipation of shortages without human intervention,

→ Possible integration with ERP tools or fuel inventory management systems,

→ Improved service rate and brand image.

Fleet managers and carriers

- Typical use case :

Monitoring fuel stored in depot tanks or in mobile tanks for powering vehicles or generators. - Specific needs :

➤ Ensure permanent supply to avoid vehicle immobilization,

➤ Accurately monitor actual consumption,

➤ Identify any drifts or leaks. - Added value :

→ Reduced fuel costs through better inventory management,

→ Complete traceability of consumption per day or per vehicle,

→ Rapid detection of anomalies.

Agricultural cooperatives, CUMAs and farmers

- Typical use case :

Shared or individual management of tanks containing biofuel for agricultural equipment. - Specific needs :

➤ Manage tanks that are often remote and not easily accessible,

➤ Consolidate data from several operators or sites,

➤ Reduce unnecessary travel to check levels. - Added value :

→ Automated monitoring without manual intervention,

→ Filling planning based on reliable data,

→ Robust solution resistant to external conditions (water, mud, cold).

Individuals committed to the energy transition

- Typical use case :

Monitoring the level of fuel oil or biofuels in a residential tank, for heating or personal consumption. - Specific needs :

➤ Be alerted in the event of low levels,

➤ Avoid service interruptions in winter,

➤ Have a simple, connected solution. - Added value :

→ Peace of mind thanks to automatic alerts,

→ Real-time monitoring via smartphone,

→ Active contribution to reducing carbon footprint by optimizing energy consumption.

Discover our connected biofuel gauge

Main technical data

Our solution is based on high-precision ultrasonic sensor technologyadapted to the needs of biofuel storage professionals. And because no two uses are the same, we offer a complete catalog of connected gauges compatible with different environments and fuels.

| Specification | Detail |

|---|---|

| Sensor type | Ultrasonic (main model), other technologies available as required |

| Connectivity | NB-IoT, LTE-M, with 2G/3G/LPWAN fallback |

| Operating time | Up to 10 years (replaceable battery, solar option) |

| Certifications | IP68, RGPD compliance |

| Operating temperatures | -20°C to +60°C |

| Fuel compatibility | Biofuels (HVO100, B100), fuel oil, RNG, additives, etc. |

| Tank formats | Steel, plastic, IBC, underground or overhead tanks |

📌 Need a specific gauge? Our team will help you find the right solution for your fuel, your environment and your constraints.

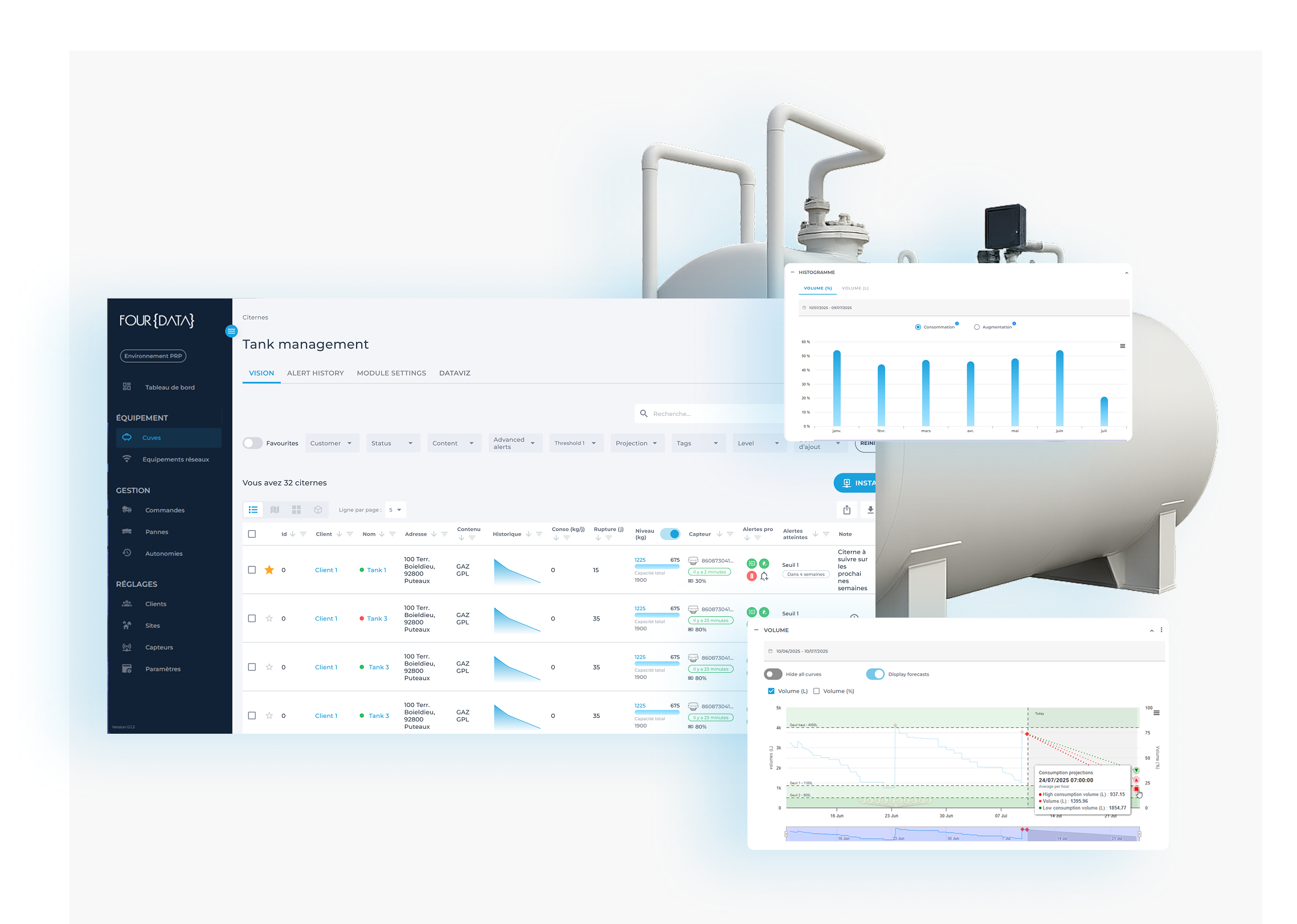

Features integrated into our IoT solution

The Four Data connected gauge is not limited to level measurement. It can be integrated into a comprehensive management platformdesigned to simplify decision-making and automate processes.

- Customizable threshold alerts (by volume, % or days remaining)

- Consumption history (by day, week, month)

- Reservoir geolocation

- Multi-tank and multi-site management

- API/ERP connection for integration into your existing systems

- Replenishment forecasts (predictive module available)

- Secure data hostingproprietary platform

Our solution transforms every tank into source of actionable dataaccessible at any time.

Quick installation and multi-tank compatibility

Because every site is different, we have designed our gauges for simple, quick and quick, simple and non-intrusive installation. The system is Plug & Play no wiring, no work, no business interruption.

But above all, you’re not alone :

👉 Four Data directly installs and sets parameters on siteanywhere in France and Europe, thanks to its network of in-house technicians.

- Deployment coordinated by our in-house teams

- Customized settings for each tank

- Post-installation maintenance and supervision (MCO contract)

Data visualization on our intuitive platform

Our web interface gives you a centralized view at a glance.

- Remote display of tank levels

- Interactive map with geolocation

- Dashboard with filters: fuel, site, alert, filling

- Data history and Excel export

- Compatible with desktop, tablet and mobile devices

Customer feedback

Case study : Oleo100, 100% French rapeseed biofuel

Background

The Group Avril wanted to increase the reliability of its supply of Oleo100, a biofuel produced from French rapeseed, while simplifying the management of tanks spread over different customer sites.

The issue

With growing demand for this alternative fuel, delivery coordination was becoming critical. Teams were faced with a lack of visibility on stock levels, leading to early replenishments, or conversely, risks of stock-outs.

Our solution

Four Data has deployed a set of ultrasonic sensors connected to customer tanks. All consumption data is uploaded in real time to our IoT platform. Thanks to an intelligent alert system, logistics teams are automatically informed of filling requirements.

The results

- Automated control via the eVMI interface,

- Precise monitoring of each tank’s level, accessible 24 hours a day,

- Save operational time and reduce unplanned interventions.

📎 See the full testimonial :

👉 Oleo100 & Four Data – Feedback

Measurable gains in the field

On a panel of over 1,500 equipped tanks, the results speak for themselves:

📊 Key performance indicators :

| Indicator | Result obtained |

|---|---|

| Reduction in kilometers traveled | -18% year-on-year at constant volumes |

| Reduction in CO₂ emissions | -12% per ton delivered |

| Return on investment (collectors + installation) | < 9 months |

| Customer satisfaction (post-project survey) | 95% (reliability, increased visibility, simplicity) |

These results confirm that the implementation of a connected gauge system goes far beyond level management: it is a strategic strategic lever for optimizing costs, securing the supply chain and and reduce the environmental impact of every liter delivered.

They trust us:

FAQ – Connected gauge for biofuels

Ask for a personalized demonstration

Our team is with you every step of the way

Whatever your sector or the volume you need to manage, we can provide you with complete supportfrom the study of your needs to system installation and maintenance.

- Advice tailored to your needs

- Recommending the most suitable gauge for your tank and fuel

- Demonstration of the data management platform

- Planning a pilot deployment

🧑💼 A Four Data expert responds within 24 hours.