Connected pellet silo gauge

: monitor your stock in real time

Connected pellet silo gauge

: monitor your stock in real time

Monitoring the level of pellets in a silo is often approximate, manual and error-prone. However, a stock shortage can lead to a sudden shutdown of the heating system, with costly consequences for the user or the company. To remedy this, our connected pellet silo gauge offers a simple, reliable and intelligent solution. simple, reliable and intelligent solution. Thanks to a high-precision sensor, it enables you to monitor levels in real timelevels, anticipate replenishment needs and ensure optimum optimal management of your stockfrom any device. Technology designed for greater peace of mind, autonomy and efficiency.

Why opt for a connected gauge in a pellet silo?

No more break-ups: anticipate your needs

A heating interruption caused by an empty silo can have immediate consequences: discomfort for homeowners, downtime for local authorities, lost time for businesses. These critical situations are generally due to a lack of visibility on the actual level of pellets in the tank.

Thanks to our connected gauge, you are alerted by SMS or email as soon as a critical threshold is reached. This ability to anticipate changes everything: you can plan your deliveries before a disruption impacts your business..

💬

Customer testimonial

:“Thanks to the Four Data Sens platform, customers can track their consumption and tank levels in real time. This also enables better monitoring by the Oleo100 customer service department, as well as by the sustainable development department.”

– Geoffroy Pertuisot, Head of Digital Innovation, Avril Group IT Department

Access your data remotely, wherever you are

From your computer, smartphone or tabletyou can follow :

- current stock level (in percent),

- daily or weekly consumption,

- the history of measurements taken by the sensor.

L’Four Data interface interface is available in web and mobile versions, with ergonomics designed for use in the field. All data is securely hostedcompliant with RGPD standards, and updated at least 4 times a day.

It’s the guarantee of simple, accessible and secure monitoringeven for non-technical users. The solution is equally suited to energy, agriculture or resource management sectors..

Control your heating costs with intelligent monitoring

Incorrect granule level monitoring can lead to :

- ❌ rushed, more expensive orders,

- ❌ unnecessary travel for distributors,

- ❌ overconsumption due to poor estimation of needs.

With our solution, you gain in precision and efficiency:

- ✅ Easy planning replenishments,

- ✅ Logistics optimization (especially for professionals with several silos),

- ✅ Historical data to refine your monthly or seasonal consumption,

- ✅ Configurable alerts according to your constraints or uses.

All from a clear interface which centralizes useful information on each connected hopper or tank.

Our solution: the NOVA /ATEX connected gauge

A radar level sensor designed for pellet silos

Unlike conventional ultrasonic systems, NOVATEX uses the latest latest-generation radar technologytechnology, particularly suited to demanding environments such as wood pellet silos. Thanks to this non-contact technology, the gauge ensures precise level measurementeven in the presence of dust, moisture or metal walls.

Its design enables reliable measurement in high siloswhere conditions vary widely. Whether your silo is underground, outside or compartmentalized, NOVATEX adapts without loss of performance.. The radar is unaffected by variations in pellet density, ensuring constant, efficient stock monitoring.

Compatibility with long-range IoT networks (NB-IoT, LTE-M)

To ensure continuous data transmissionthe NOVATEX connected gauge is compatible with several long-range, low-power networksadapted to the needs of industrial IoT.

| 📌 Problem encountered | ✅ Result obtained |

|---|---|

| Unplanned stock-outs and manual delivery planning | Precise real-time visualization of fuel levels, enabling optimized deliveries |

| Frequent and inefficient emergency interventions | Reduce unnecessary routes and automate alerts to avoid emergencies |

💡 These networks enable the gauge to be autonomous for several yearswithout the need for a Wi-Fi connection or network cabling, making it ideal for remote or hard-to-reach sites.

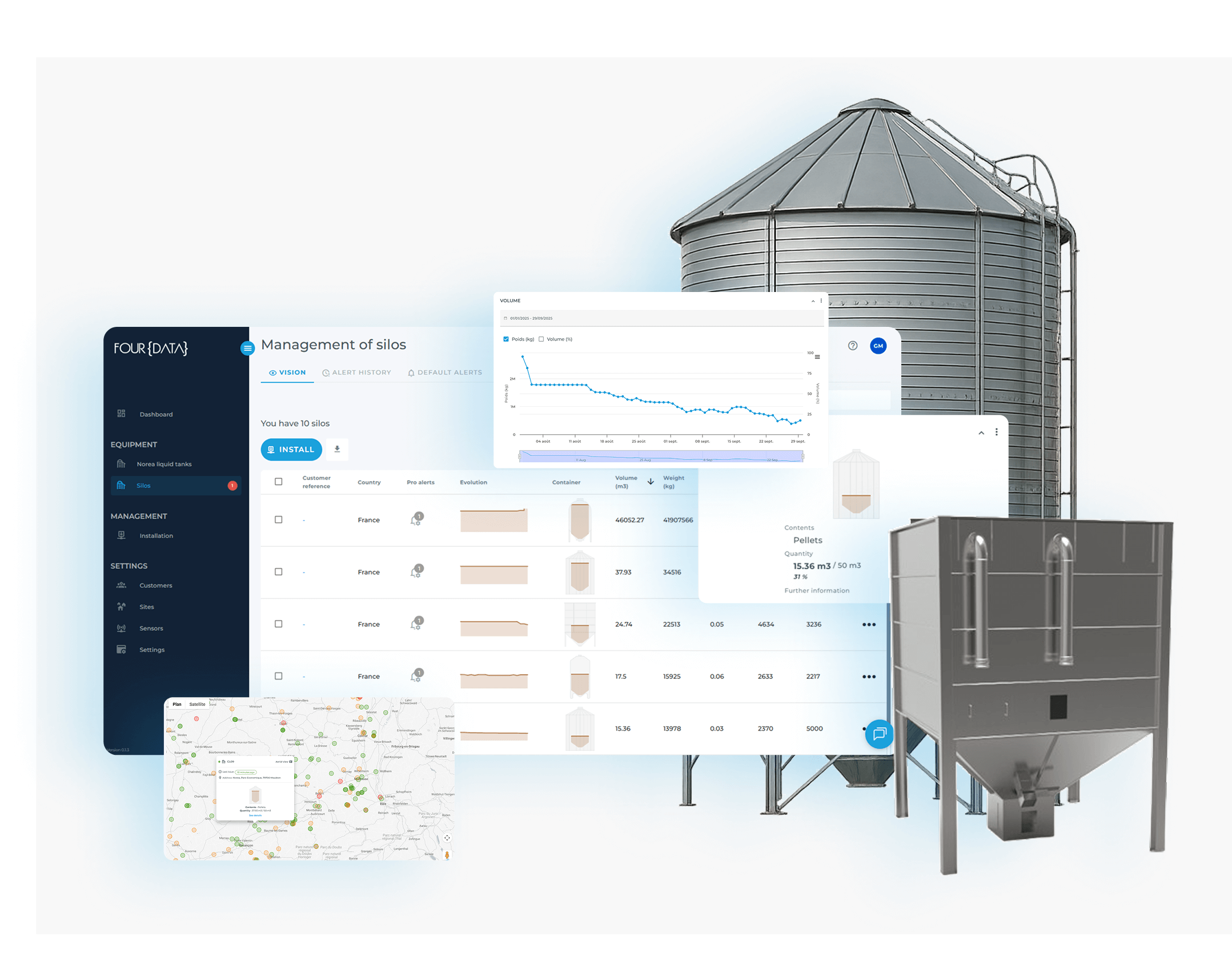

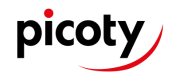

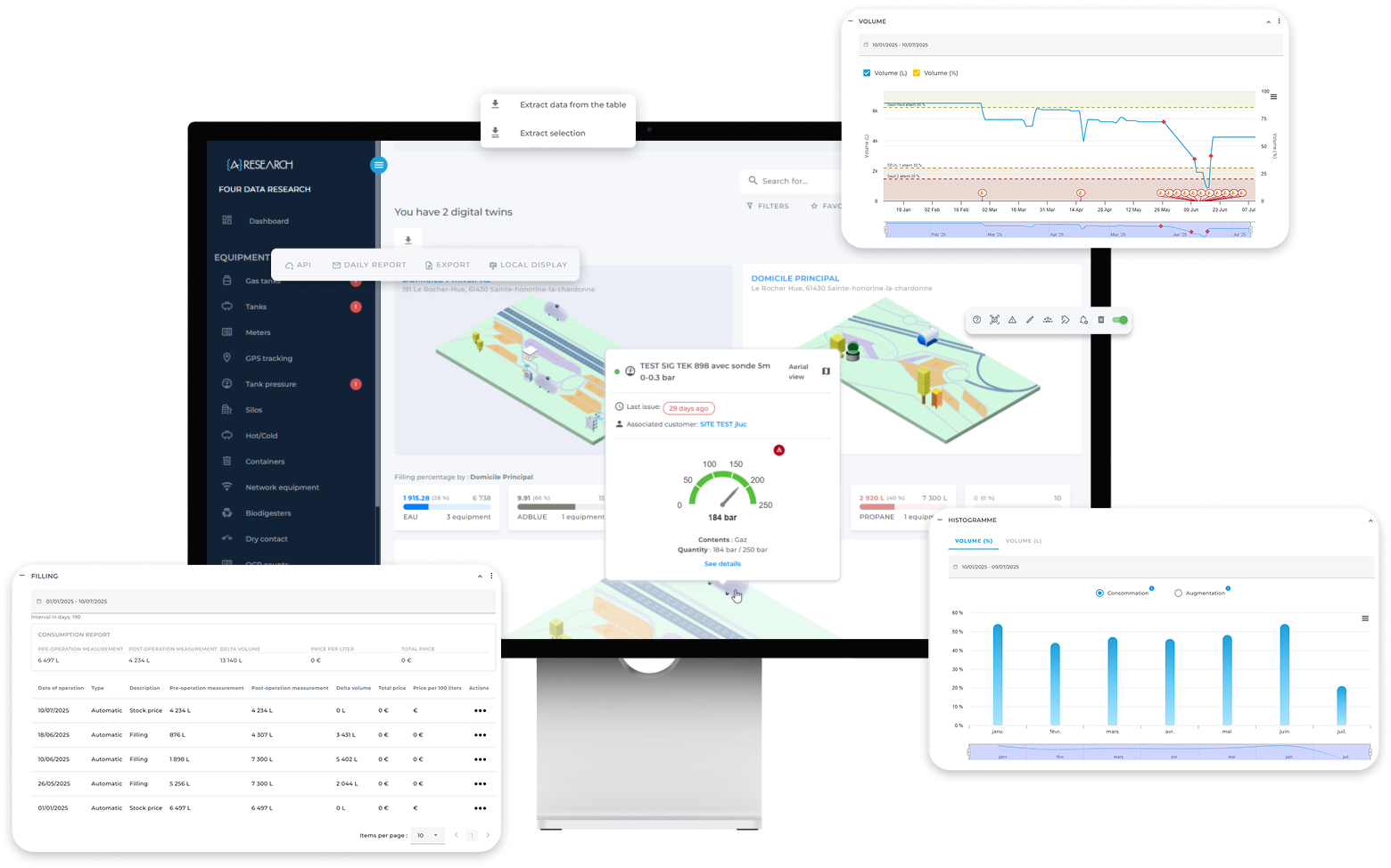

Data consultation on our Four Data IoT platform

The data measured by the gauge is transmitted to our secure web and mobile interface. Designed to be intuitive and modularthe Four Data platform offers a clear clear visualization of percentage levelslevels consumption curveas well as a complete history for each connected silo.

Key functions include :

- Multi-site and multi-silo monitoring,

- Define customized alert thresholds,

- SMS or email notification when action is required,

- Possibility of delegating replenishment management to your supplier.

🔒 All data are hosted in France, in compliance with the RGPD, and accessible at any time from any connected device.

Autonomous, robust and easy to install

The NOVATEX gauge is designed to operate autonomously and durablyeven under the most demanding conditions:

- Autonomy of several years (depending on measurement frequency and network configuration),

- IP66 sealing resistant to rain, dust and temperature variations,

- Installation without major work All you need to do is drill a hole in the silo,

- On-site intervention by a Four Data technician possible.

It can be installed on a vertical silo a vertical silo, a compartmentalized hopper or a pellet tankwithout disrupting daily use. Result: rapid commissioning, immediate immediate follow-upand zero stress for the user.

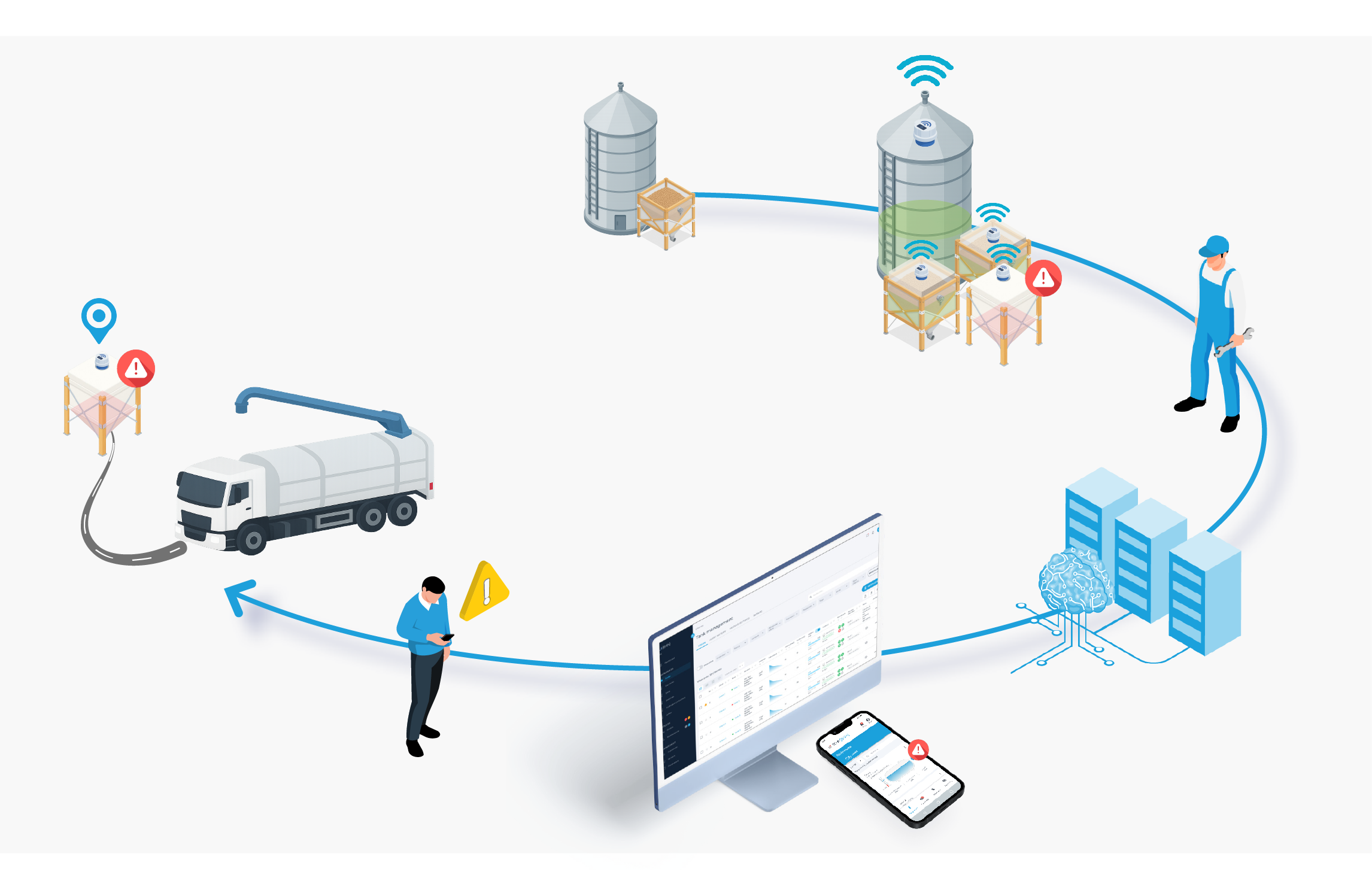

How it works

Sensor → Network → Platform: a complete chain

The NOVATEX connected gauge is based on a simple, robust simple, robust architecturein three key stages:

- Radar sensor installed on the top of the silo, it measures the filling height without contact with the material. Each measurement is translated into a filling percentage.

- IoT network Data are transmitted via NB-IoT, LTE-M or LoRadepending on coverage and environment (rural areas, indoor silos, etc.).

- Four Data platform: information is aggregated on a secure online interface, accessible from any device.

💡 This transmission chain ensures smooth, automated smooth, automated monitoringwithout manual intervention or complex network infrastructure. A ready-to-use technologydesigned for users of all levels, from private individuals to professionals.

View your levels in real time

Once the data has been received, you can consult your silo level at any timein :

- of filling percentage (e.g. 76%),

- d’consumption history over several days or weeks,

- of emptying trend to anticipate the replenishment date.

Measurements are taken at least 4 times a dayfor accurate monitoring without data overload. L’graphic interface is easy to read, even for users unfamiliar with digital tools.

Whether you manage a single tank or several hoppers spread over several siteseach silo has its own tracking sheet.

Receive personalized alerts and plan your deliveries

To ensure smooth management of your inventory, you can define alert thresholds adapted to your activity. For example:

- 🔔 Alert at 30 % to anticipate a classic order,

- 🔔 Alert at 15 % for emergency or automatic restart.

Notifications are sent by email or SMS to the designated person(s) (yourself, an employee, a partner distributor).

💬

Example of an alert received

:

Subject: Low level alert – Silo n°2

Current stock: 18

Think about planning your next delivery.

This personalized alert service service facilitates replenishment logisticsfor both private individuals and companies with silos. It avoids oversights, emergencies and forecasting errors.

Who is this connected gauge for?

| 👤 Profile | ⚠️ Problems encountered | ✅ NOVATEX gauge benefits | 👉 Recommended action |

|---|---|---|---|

| 📊 Pellet distributors |

|

|

🔗 Connect your customers to automate your rounds |

| 🏠 Individuals & pellet boiler owners |

|

|

🧰 Ask for a turnkey NOVATEX installation |

| 🏢 Heating plant managers |

|

|

☘️ Centralize your energy consumption data |

| 🛠️ Silo manufacturers & installers |

|

|

🤝 Of fer a connected version of your silos today |

This connected gauge can be integrated into both industrial projects, agricultural or domestic projectswith the same the same promise: visibility, safety, efficiency.

Real-life use cases

Optimizing delivery rounds for a distributor

Situation & benefits Intelligent pellet management enables distributors to monitor pellet levels in customer silos in real time. This enables them to plan deliveries according to actual needs, reduce unnecessary rounds and avoid delivery emergencies.

Facts and figures Some customers have reported up to 32% in logistics savings and the elimination of emergency deliveries.

User testimonial This result comes from the customer experience described on the Four Data website: “32% logistical savings and no more urgent pellet deliveries!

Remote management of multiple silos in a community

Situation & benefits By integrating connected sensors on several silos, managers can continuously monitor stock levels, centralize information and anticipate needs without having to visit the site. This remote monitoring enhances service responsiveness and reliability.

Facts and figures Four Data’s intuitive intuitive web and mobile interfaceaccessible to all (individuals or professionals) and facilitating multi-site monitoring.

Avoiding a home heating breakdown

Situation & benefits With a single pellet silo, even for a private home, automatic monitoring avoids unexpected breakages, ensuring continuous thermal comfort. Anticipated levels prevent heating failures, especially during critical periods.

User feedback A customer testimonial from the agricultural sector illustrates this peace of mind: “I always know where I stand with my silos. I don’t have to wait for a shortage to order. – EARL du Champ de la Croix

Why choose Four Data for your IoT project?

From idea to deployment: comprehensive expertise

We support you at every stage of your IoT project, fromideation (context analysis, definition of needs, feasibility study) to the phase of deployment (prototyping, piloting, industrialization), right through to follow-up (training, maintenance, data exploitation).

This

proven methodology

guarantees you a concrete, sustainable and profitable project.

Customized, agnostic platform

Our platform is modular and fully customizable It accepts all types of sensor (gauges, pressure sensors, GPS, etc.) and is compatible with different networks (Sigfox, NB-IoT, LTE-M, etc.), whatever your use case or sector.

Whether you’re in agri-food, industry or services, we’ll tailor the solution to your specific needs.

More than 60,000 connected objects deployed

We design and manufacture our sensors in France, with over 6,000 units already deployed with over 500 customers in Europe.

Proof of our technical expertise and operational maturity maturity.

Dedicated, responsive customer support

Our platform is designed to be fun and easy to use – so much so that we insist that the data collected must be useful and accessible on a daily basisas close as possible to field operations.

You benefit from

dedicated support

always ready to intervene to guarantee the performance and efficient use of your solution.