Mobile tank

– Secure, connected monitoring of your transportable tanks

– Secure, connected monitoring of your transportable tanks

Whether it’s diesel, petrol, RNG, AdBlue or waterthe mobile tank has become a must for professionals who must ensure storage and refuelling their vehicles and machines directly on the construction site or in mobile station. However, the transporting fuel is not without risks: compliance with the ADRstandard, prevention of leaks or spills, guaranteed safety of operators.

With our connected solutions, you can monitor your tanks and tanks and cisterns (steel or polyethylene, single- or double-walledwith or without retention tank). You gain in quality monitoringquality, reduce losses and simplify your refuelling operations with reliable tools designed for the most demanding environments.

TABLE OF CONTENTS

- What is a mobile tank?

- The different types of mobile tanks

- Issues related to mobile tanks

- Our connected solution for mobile tanks

- Exclusive OEM offer from ALOREM x FOUR DATA: the mobile tank is already connected!

- Technical specifications and operation

- Installation

- Collection

- Analysis

- Alerts

- Why choose our connected mobile tank solution?

- Real-life use cases

- FAQs on mobile tanks

- Request a demonstration of our connected solution

What is a mobile tank?

Definition and common uses (CNG, fuels, water, AdBlue, etc.)

A mobile tank is a transportable tank designed for storage and refueling of various liquids : fuels (diesel, RNG, gasoline, AdBlue)but also water or specific products. Unlike fixed tanks, it is easy to move from one site to another, and complies with safety standards. ADR safety for hazardous products. These tanks are available in steel or polyethylenewith single- or double-walled and sometimes a retention tank to limit the risk of pollution.

👉 They offer professionals a practical solution for powering their equipment or ensuring business continuity.

Frequent use :

- Refuelling fuel (diesel, RNG, gasoline) for vehicles and machines.

- Temporary storage ofwater orAdBlue on site.

- Mobile power supply for stations or remote work units.

- Safe transport of hazardous liquids (with pump and dispensing gun).

Sectors concerned (construction, agriculture, transport, equipment rental)

- BTP supply site machinery directly on site → e.g. a 1,000-liter tank supplies bulldozers and generators.

- Agriculture GNR or water distribution for agricultural machinery and greenhouses → e.g. a 600-liter mobile tanker equips a tractor at the height of the season.

- Transport & logistics management of internal depots and stations for fleets of vehicles → e.g. a carrier equips its parking lot with several ADR-secured mobile tanks.

- Equipment rental: turnkey service for supplying fuel to rented machines → e.g. a rental company offers a mobile tank with integrated pump and nozzle.

The different types of mobile tanks

IBC tanks and intermediate containers

| Type | Usage | Benefits |

|---|---|---|

| IBC 1000 L polyethylene | Transport of fuel (RNG, diesel) or water | Standard format, easy to move and stack |

| Steel-reinforced IBC | Chemicals, oils | Better impact resistance |

IBC (Intermediate Bulk Container) are among the most widespread. Their 1000-litre format is well suited to construction sites oragriculture for simple transport of fuel, water or AdBlue. In the polyethylene or steelThey offer professionals maximum flexibility.

Mobile tanks with integrated geolocation

| Type | Usage | Benefits |

|---|---|---|

| 400 L CNG tank with GPS | Refueling of construction machinery | Position tracking and theft prevention |

| ADR 330 L petrol tank | Vehicle fleets | ADR safety + traceability of movements |

These mobile tanks incorporate a GPS sensor which transmits position in real time. This enables companies to secure their reservoirs and track usage on different sites. Widely used in the transport and logisticsThey reduce the risk of loss and guarantee total compliance.

Double-walled mobile tank for added safety

| Type | Usage | Benefits |

|---|---|---|

| 900 L double-wall steel tank | Fuel and diesel oil | Reinforced protection against leaks |

| Polyethylene tank with retention tank | Dangerous goods | ADR safety, reduces potential pollution |

The double wall is a guarantee of safety for storing fuels and hazardous products. These tanks comply with ADR and offer enhanced protection against leakage and contamination. Indispensable for sensitive sites (in-house stations, depots, construction sites).

Specific transportable containers and equipment (AdBlue, fuel, water, etc.)

| Type | Usage | Benefits |

|---|---|---|

| AdBlue 200 L mobile tank | Recent vehicles | Compatible with specific pumps and guns |

| 600 L water tank | Agricultural irrigation | Lightweight, easy to transport on trailer |

| 400 L fuel tank with 12V pump | Machines and equipment | Rapid on-site refuelling |

To meet specific needs, there are dedicated tanks forAdBlueforwater or fuel oil. They are often equipped with a pump and a dispensing gunfor professional professional refuelling directly on site.

Issues related to mobile tanks

The use of mobile tanks for storage and transport of fuels (diesel fuel, gasoline, RNG, AdBlue) meets the essential needs of professionals in the construction, agriculture and transport sectors. But it also brings with it a host of challenges: respect for the ADR complianceThe right choice and management of a mobile tank means you can be sure that your products are safe, that hazardous products are managed, that losses are prevented and that costs are kept under control. Choosing and managing a mobile tank means guaranteeing both security, l’logistical efficiency and quality of service in the field.

Safe fuel transport and ADR compliance

- Compliance with ADR standards for the transport of fuels and hazardous products.

- Use of suitable tanks (steel or polyethylene, single- or double-walled) is mandatory.

- Safety accessories: pump, gun, drip tray.

Risk of leakage, fire or theft

- Possible leaks when refueling on site.

- Fires linked to inappropriate fuel storage.

- Frequent fuel theft from isolated or unattended sites.

Costs associated with manual management of stocks and supplies

- Repeated movements to check levels.

- Additional logistics costs for urgent deliveries.

- Poor anticipation of fuel requirements in liters for machines and vehicles.

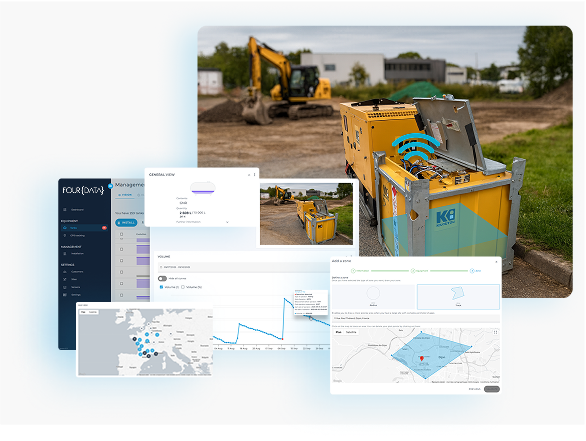

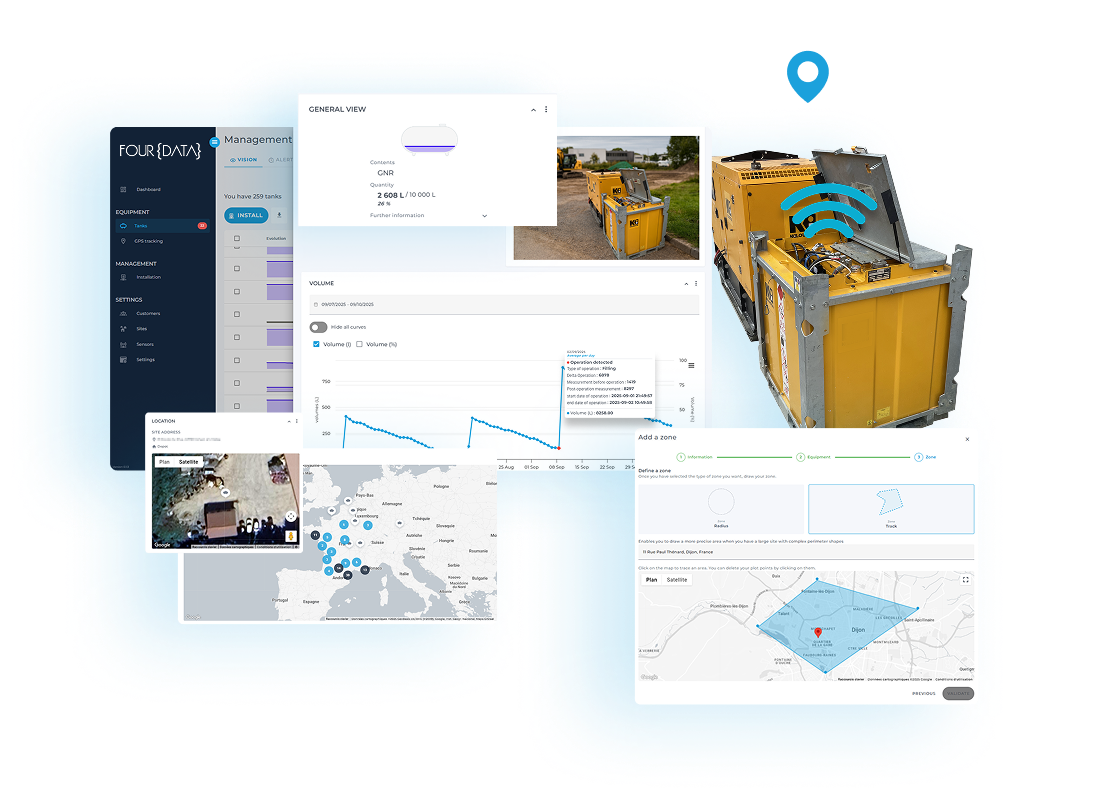

Our connected solution for mobile tanks

The Four Data connected gauge for transportable tanks

Our connected gauges are installed directly on your mobile tanks (steel or polyethylene, single- or double-walled, with drip tray). They continuously measure FUEL LEVEL (diesel, petrol, RNG, AdBlue) and automatically transmit the data to our secure platform. This solution is suitable for all tank formats, from small 200-liter models to tankers of several thousand liters.

💡 Ideal for tanks equipped with Rotarex, Cotrako or Rochester systems, it adapts perfectly to existing installations without modification.

Real-time monitoring of levels and movements

Thanks to our intelligent sensors, you can see in real time :

- The exact volume available in each tank.

- L’evolution of consumption by day, week or month.

- The fuel movements (filling, refueling).

👉 No more manual checks: all information is just a click away from the web interface or mobile app.

Reservoir geolocation and geo-fencing

Each tank can be equipped with a geolocation module. You track their precise position and receive an alert if a tank leaves a defined zone (geo-fencing). This functionality is essential for securing your assets and limiting the risk of theft or fraudulent use, particularly on construction sites or in isolated depots.

Automatic alerts (low thresholds, displacement, anomalies)

Our gauges can be used to define customized thresholds :

- Low threshold alert → anticipation of fuel delivery.

- Displacement alert → detection of theft or unexpected movement.

- Anomaly alert → leak or abnormal consumption.

📩 Sample notification :

“⚠️ 900 L RNG tank – East job site: low level (15% remaining). Plan to refuel.”

TOWERCELL LOCATOR – Precise location without GPS

The TOWERCELL LOCATOR is a complementary option available with FOUR DATA connected gauges.

This technology is based on the principle of cellular triangulation, which enables a sensor to be located by analyzing the signals it emits and its position relative to three network antennas.

By cross-referencing the data from these antennas, the platform determines the location of the sensor with a high degree of accuracy, without the need for a GPS module.

This approach offers several advantages: reduced energy consumption, better coverage in isolated areas and optimized operating costs.

👉 With the TOWERCELL LOCATOR option, users benefit from a reliable and accessible geolocation solution, perfectly integrated with the FOUR DATA connected platform for intelligent tracking of mobile and transportable tanks.

Exclusive OEM offer from ALOREM x FOUR DATA: the mobile tank is already connected!

ALOREM

has developed an exclusive offer in partnership with FOUR DATA to provide its customers with a complete, connected experience from the moment they purchase their mobile tank.

👉 All ALOREM tanks now come with a FOUR DATA connected gauge installed and ready to operate. Thanks to this integration, users benefit from real-time fuel level monitoring, precise geolocation and direct access to the FOUR DATA connected platform to view their consumption, alerts and history.

Subscription renewal is simple, via FOUR DATA’s secure online space, guaranteeing uninterrupted service. Non-activated tanks are not billed, and subscriptions start only when the gauge is effectively activated.

This ALOREM x FOUR DATA offer provides professionals in the construction,agriculture and transport sectors with an intelligent, ADR-compliant mobile tank, ready for use and connected as soon as it is commissioned.

Thanks to multi-network IoT technology and the FOUR DATA SaaS platform, users gain in autonomy, safety and performance, while simplifying the day-to-day management of their tanks.

Technical specifications and operation

Measurement technologies (ultrasound, radar, connected sensors)

Our probes use different measurement technologies depending on the type of tank and product:

- Ratiometric: Ideal for tanks with Rochester / Cotrako / Rotarex gauges already installed

- Ultrasonic : ideal for diesel, RNG, water → non-contact, reliable and fast measurement.

- Radar : recommended for chemicals or oils → high precision, insensitive to temperature variations.

- Pressure sensors: suitable for underground or high-capacity tanks.

Multi-network IoT connectivity (NB-IoT, LoRa, Sigfox, GSM)

Data transmission is based on multi-network connectivityconnectivity, guaranteeing coverage everywhere :

- Sigfox / LoRa low energy consumption, perfect for isolated sites.

- NB-IoT / GSM (LTE-M): high-speed, suitable for urban and industrial areas.

👉 This flexibility allows continuous operation, even outdoors or in white zones.

SaaS platform: visualization, alerts, customized reports

All data flows back to our SaaS platform :

- Customized dashboards.

- Real-time alerts on low levels or anomalies.

- Detailed reports to optimize your delivery logistics.

Easy installation and autonomy

- Plug & Play installation Sensor mounted directly on the tank (steel, polyethylene, single- or double-walled).

- Battery life up to 10 years depending on frequency of readings.

- Low-maintenance: robust and suitable for demanding environments (construction sites, farms, stations).

Summary table

| Features | Values |

|---|---|

| Sensors | Ratiometric, Ultrasonic, Radar, Pressure |

| Products measured | RNG, diesel, gasoline, AdBlue, water, chemicals |

| Connectivity | NB-IoT, LoRa, Sigfox, GSM |

| Battery life | 5 to 10 years |

| Installation | Plug & Play (fast, no major work required) |

| Platform | SaaS, multi-site, multi-vat |

How it works ?

Why choose our connected mobile tank solution?

Regulatory compliance and safety (ADR, hazardous materials)

- Tanks complying with ADR requirements for transporting fuels and hazardous products.

- Double double wall and drip tray for maximum safety.

- Dispensing accessories (pump, gun) adapted to professional standards.

Reduce logistics costs and optimize routes

- Reduce unnecessary travel thanks to real-time tracking.

- Planning deliveries according to actual tank levels.

- Fewer emergency deliveries, with direct savings in fuel and time.

A reliable, proven solution (+1000 customers and +19,000 objects deployed)

- More than 1000 business customers already place their trust in Four Data.

- 19,000 connected objects in the field.

- Proven reliability in demanding environments: construction sites, farms, industrial depots.

Dedicated customer support

- A single point of contact for every project.

- Team training and installation assistance.

- Responsive support: answers guaranteed within 24 hours.

💬 Customer testimonial

“Since we installed the Four Data connected gauges, we’ve halved the number of trips we make to check the tanks, and eliminated the need for emergency refueling. It’s a real time and safety saver for our teams.” – Logistics Manager, Construction sector

Real-life use cases

Construction and worksites: refuelling site machinery

| Problem | Solution |

|---|---|

| Difficulty anticipating fuel requirements on worksites. | Real-time monitoring of mobile tanks (GNR, diesel) with low threshold alerts. |

| Frequent trips to check levels. | Reduce journeys thanks to the Four Data platform. |

Mini-case study – construction sector

A logistics manager in the construction industry used to monitor tank levels manually on several construction sites. Since installing our connected gauges, he consults the Four Data dashboard every morning. Result: halving travel timeeliminating emergencies and ensuring safe, planned machine refueling.

Agriculture: irrigation, agricultural fuel, water transport

Mini-case study – agricultural sector

A farmer had to weigh his tanks every week to secure his fuel supplies. Thanks to Four Data probes, he receives automatic alerts and anticipates his deliveries. This has enabled him to avoid several machine stoppages at harvest time, and to better distribute the use of its tanks.

| Problem | Solution |

|---|---|

| Risk of breakdown at the height of the season due to lack of available RNG. | Connected gauge to warn before breakdown. |

| Manual management of several dispersed tanks (fuel oil, water, liquid fertilizers). | Centralized data on a single interface. |

Transport & logistics: multi-site management and mobile fleet

| 🚨 Problem | ✅ Solution |

|---|---|

| Fuel theft from unattended depots. | 📍 Tank geolocation + alerts in the event of unplanned movement. |

| Poor replenishment planning. | 📊 Multi-site visualization and centralized monitoring. |

Mini-case study – transport sector

One carrier was using several internal depots without global visibility. By deploying our connected gauges, he obtained a global complete traceability of tanks and reduced its emergency deliveries. Its teams now plan replenishments a week in advance.

Rental & maintenance: monitoring of mobile equipment (boiler rooms, temporary tanks)

Mini-case study – maintenance sector

A company renting out generators equipped with mobile tanks chose Four Data to better monitor its tanks. The result: fewer emergency calls and more transparent billing for customers thanks to consumption reports.

| Problem | Solution |

|---|---|

| Lack of visibility on the use of leased tanks. | Remote monitoring thanks to connected probes. |

| Customer returns for unanticipated fuel failure. | Automatic alerts sent before critical threshold. |