OCR sensor for gas meters modernize your meter reading

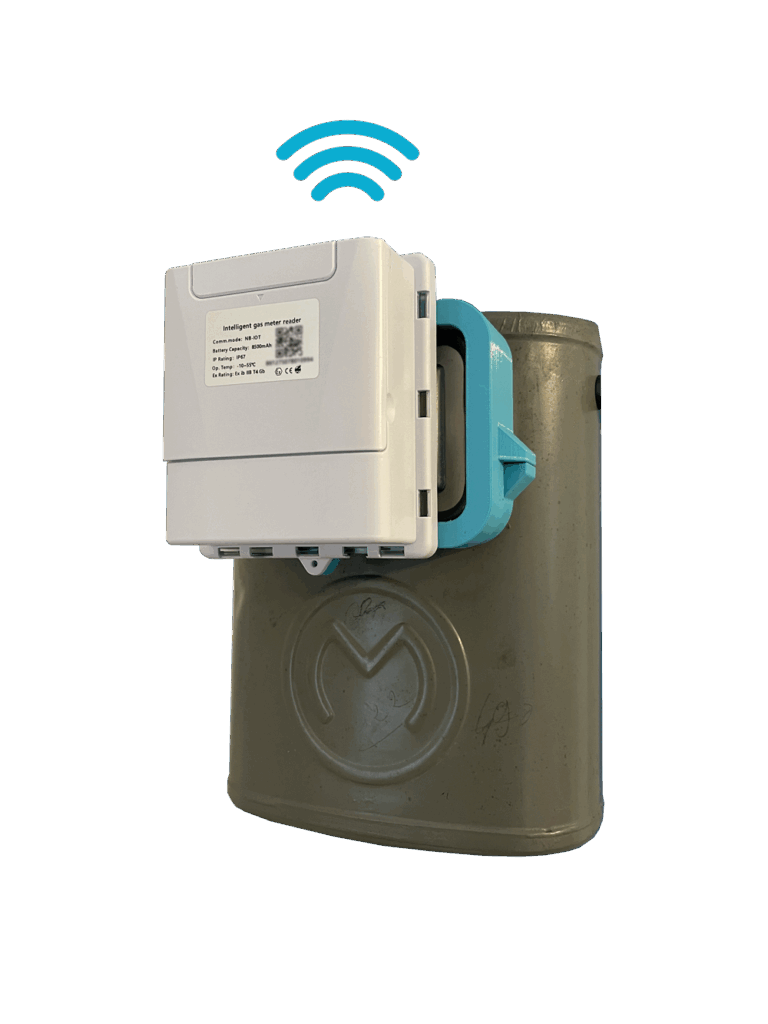

In an industrial context where data reliability, safety and responsiveness are top priorities, our OCR sensor for gas meters offers you an innovative solution that can be easily adapted to your gas meters (even the oldest!). Thanks to intelligent optical readingis used to transform an analogue analog meter meter into a connected devicewithout modifying the original installation.

Easy to install, robust and designed to withstand demanding industrial environmentsenvironments, this sensor captures the meter index accuracyeven under difficult conditions. He then passes on the remotely measured datavia NB-IoT, LoRa, Sigfox NB-IoT, LoRa, Sigfox, LTE-M or Wi-Fito our supervision platform.

By combining embedded vision, AI OCR and IoT connectivityconnectivity, this solution meets the needs of gas, chemical and local authority professionals looking for added value in the management of their energy resources.

TABLE OF CONTENTS

- The challenges of gas meter reading in industry

- Our solution: the intelligent OCR sensor for gas meters

- What you gain with our OCR sensor

- Key technical features

- Examples of concrete applications

- Why choose Four Data for your gas IoT project?

- Definition

- Selection

- Field test (POC)

- Scale-up

- Post-installation follow-up

- FAQ – Your questions, our answers

- Let’s discuss your project

The challenges of gas meter reading in industry

The limitations of traditional analog meters

- Time-consuming manual readings subject to human error

- Difficult access to some meters located at height or in sensitive areas

- No automatic data feedback

- Impossible to analyze in real time

- Risks of litigation arising from transcription errors

In many industries, analog meters are still the norm. But their reading relies on a repeated physical interventionwith timescales and uncertainties incompatible with today’s performance requirements.

Safety, compliance and efficiency issues

Manual access to meters, which are sometimes located high up, near pressurized pressure pipes or chemical chemical equipmentThis can expose operators to the risk of accidents. What’s more, the lack of automation complicates the regulatory traceabilityThis is particularly true when it comes to archiving measurements. Finally, without reliable, continuous data, it is difficult to anticipate over-consumption or a malfunction on the distribution line.

Why digitize your statements?

| Criteria | Manual method | Connected OCR sensor |

|---|---|---|

| Reading frequency | Weekly or monthly | By the minute or according to a defined parameter |

| Safety | Physical movement, ground risk | Remote reading, no contact |

| Costs | Recurring labor | Amortized investment, zero marginal cost |

| Data reliability | Risk of human error | Reliable digital data |

Our solution: the intelligent OCR sensor for gas meters

What is an OCR sensor?

A OCR sensor (Optical Character Recognition) sensor is an intelligent device capable of automatically reading values displayed on a meter with the help of an on-board camera and an optical character recognition. Suitable forgas industryThis new device allows you to visually convert the digits displayed on a mechanical index into precise digital data. precise digital datawithout modifying the existing infrastructure.

Operating principle (reading, processing, transmission)

- Capture of the meter index using an integrated high-definition camera.

- On-board artificial intelligence OCR analysis: automatic recognition of mechanical index digits.

- Local processing quality control and conversion into usable data.

- Transmission via IoT network (LoRa, NB-IoT, Sigfox, LTE-M or Wi-Fi) to the Four Data cloud platform.

This process guarantees fast, reliable reading, independent independent of physical access to the meter.

Quick installation, without replacing the existing meter

Thanks to its different adapter rangesThe OCR sensor attaches directly to the meter glass in just a few minutes. No drilling or device replacement is required. This non-intrusive installation can be carried out without interrupting activity, and adapts to a wide variety of models standard of gas meters.

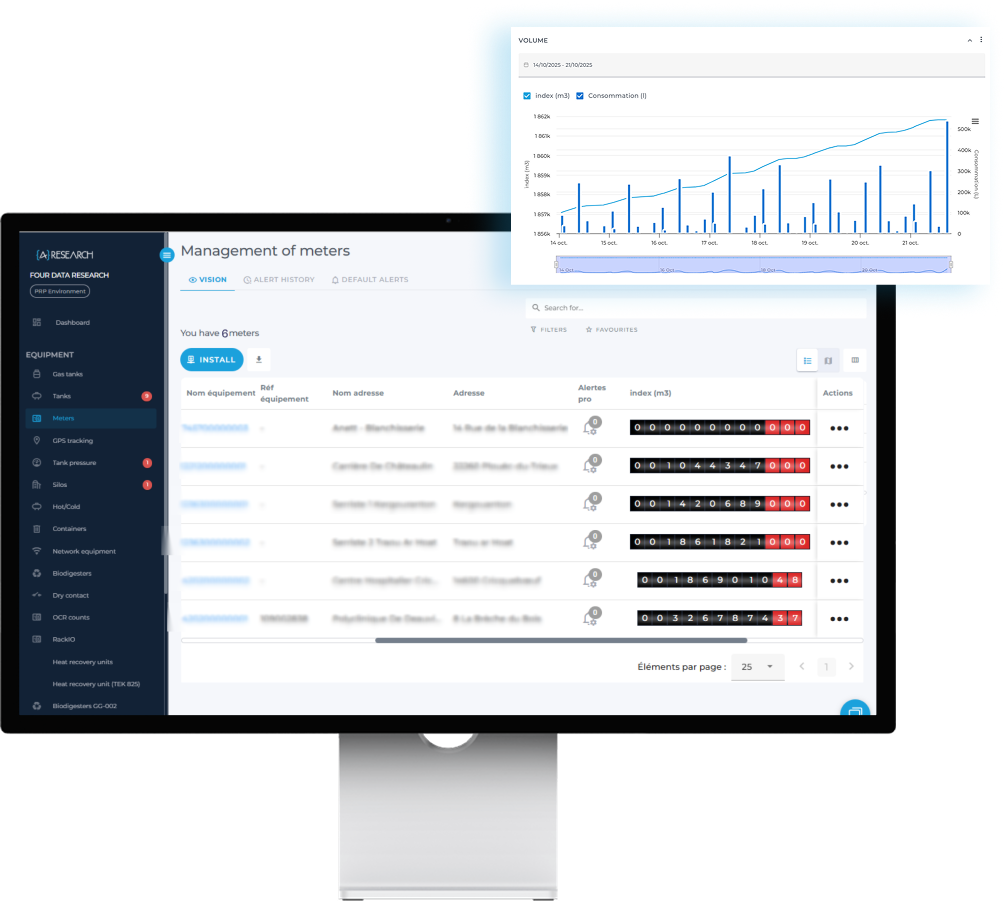

Direct integration with our IoT platform

Our OCR sensor is natively connected to the Four Data platform. Once the sensor has been installed, the data is automatically sent to the OCR countingThe data can be accessed in real time, historized and exploited via API. The interface allows you to view the measured valueset alert thresholds, or monitor several sites remotely.

What you gain with our OCR sensor

Lower operating costs

Manual meter reading involves regular travel, staff mobilization and time-consuming administrative management. Thanks to automation, the OCR sensor can reduce these costs by up to 30% for a multi-site fleet. Fewer interventions, fewer errors, fewer disputes.

Automated remote readings

Measurement frequency is no longer constrained by human availability. The sensor automatically sends the data to the platform, enabling continuous monitoring, even on remote or hard-to-reach installations.

Enhanced safety and regulatory compliance

- No contact required with meters in high-risk areas (chemical concentration, confined areas, height)

- Limits travel in potentially dangerous environments

- Automatically time-stamped and historized statements

- Easy compliance with data traceability requirements

- Alignment with industrial sites’ QHSE policies

Real-time data access

Data from OCR reading is instantly accessible on the Four Data platform. You can visualize indexes, configure customized alerts (abnormal value, absence of signal) and exploit historical data via dashboards or API export.

Key technical features

Compatible with standard gas meters

Thanks to its adaptable mounting brackets included in the kit, our OCR sensor can be installed on the vast majority of analog gas metersincluding the oldest. No equipment replacement required.

📌 Compatibility assured with :

- Gas meters with mechanical rollers (type G1.6, G2.5, G4, G6, etc.)

- Counters circular or linear dial

- Meters installed in demanding industrial environments

- Can be installed on flat, curved or glazed surfaces

Power supply, autonomy and field resistance

| Parameter | Value |

|---|---|

| Power supply | 8500 mAh lithium battery |

| Estimated autonomy | Up to 6 years (depending on measurement frequency) |

| Operating temperature | -20 °C to +60 °C |

| Protection class | IP68 (dust and waterproof) |

| Weight | 350 g |

| Material | High-strength polypropylene |

The sensor is designed to withstand harsh field conditions, including dust, humidity and frequent temperature variations.

Multi-network IoT connectivity: Sigfox, LoRa, NB-IoT, LTE-M, Wi-Fi

Data transmission takes place via several IoT wireless networks wireless networks, enabling flexible integrationintegration, regardless of existing network environments or infrastructures.

📶 Supported networks and benefits :

- LoRa low power consumption, long range in rural areas

- NB-IoT excellent indoor penetration, stability

- LTE-M : extended coverage, reduced latency, mobility

- Sigfox simplicity of deployment, low cost

- Wi-Fi useful for wired industrial or urban environments

💡 A network coverage map can be provided to identify the best option for your location.

OCR accuracy and reliability

The sensor’s integrated optical recognition module achieves accuracy rate of over 98%.even in uneven lighting conditions or on slightly uneven surfaces. On-board intelligence also enables self-checking of data and detection of reading anomalies.

Examples of concrete applications

Heavy industry: consumption monitoring and alerts

In a plant producing insulating materials, the gas meters feeding the furnaces were scattered over several lines and high-temperature zones. The installation of OCR sensors made it possible to continuous monitoring of consumptionwith automatic alerts when thresholds are exceeded. The result: a 12% drop in abnormal consumption in less than 3 months.

Distribution networks: automated multi-site surveys

A gas transmission company operates over 50 metering points throughout France. By deploying our OCR solution, it has centralized all readings on a single interface. More than 150 readings a day are now automated, reducing intervention times and ensuring more reliable billing data.

Local authorities: centralized management and compliance

Several municipal utilities have equipped their gas meters with OCR sensors to facilitate remote management of public buildings (schools, town halls, gymnasiums). This approach has enabled data centralizationsimplified simplified regulatory reportsThe system also provides rapid detection of abnormal consumption, particularly during shutdown periods. Example: the municipality of X (anonymized) reduced its energy losses by 18% in one year.

Why choose Four Data for your gas IoT project?

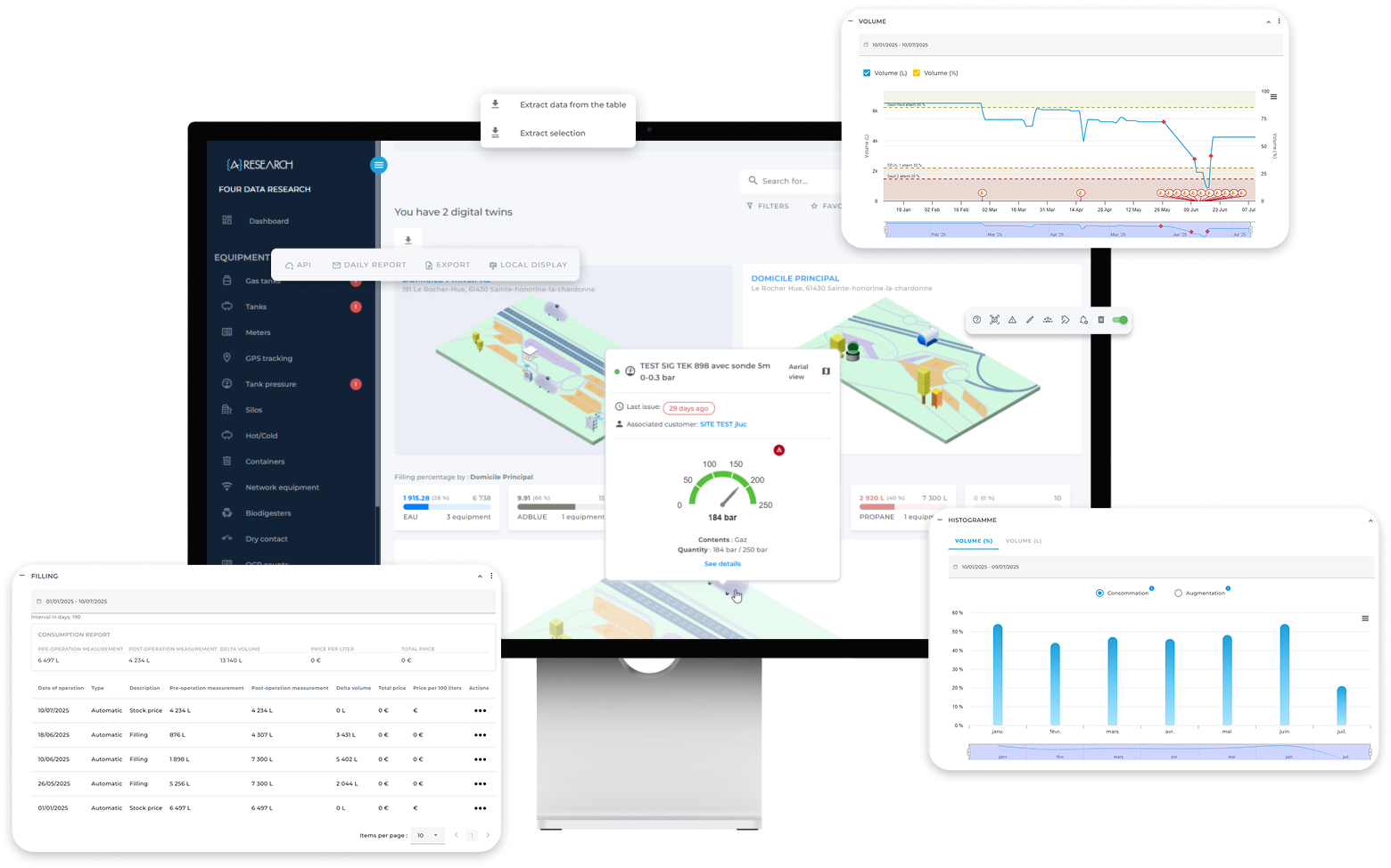

A complete solution: sensor + platform + network

Four Data offers a fully mastered value chain, from the intelligent OCR sensor sensor to data restitution via our IoT platform. This integrated model guarantees native compatibilitycompatibility end-to-end reliabilityand simplified project management.

Our platform is agnostic agnostic: if you already have third-party sensorswe can integrate them to offer you unified unified supervision of all your installations.

Proven, modular technology

Our technology is designed to adapt to your constraints, whatever your type of meterenvironment or level of requirement. Visit modular of our offer means that gas meter reading can be complemented by other sensors dedicated to storage tanks (LPG, LNG, etc.)for a overall of your consumption.

📦 To be provided in a box :

- Multisensor compatible (OCR, gauge, pressure, level, etc.)

- Single platform for network gas and LPG

- Integration with ERP, PLC, SCADA

🔗 See our complementary solution dedicated to gas tanks: LPG connected monitoring

Support from A to Z: from ideation to deployment

Whatever the level of maturity of your project, we’ll support you step by step right through to operational implementation:

Dedicated, responsive customer support

Our customers particularly appreciate proximity and availability of our technical and sales teams.

💬 Customer testimonial

“Four Data was able to quickly understand our specific needs and reacted efficiently to deploy a complete solution. Today, we benefit from real-time supervision and real control comfort.”

– Geoffroy PertuisotIT Department, Groupe Avril

A dedicated team accompanies you from diagnosis to data enhancement, with responsive responsive online supportclear documentation and an intuitive interface.

They trust us:

FAQ – Your questions, our answers

Let’s discuss your project

Contact our IoT experts

Are you planning to digitize your gas or multi-fluid meters?

Our teams can advise you every step of the way.

Request a demo or POC

Put our solution to the test.

Test the OCR sensor on your own site with a personalized personalized demo or a Proof of Concept.

Discover the real performance of our solution under your operating conditions.