Telemetry solution for tanks on ICPE & SEVESO sites: secure your sensitive installations with precision

On ICPE and SEVESO sites, tank and silo management is not just a question of efficiency: it’s a major issue of safetysafety regulatory compliance and environmental protection. Each uncontrolled emissionsevery time a critical critical threshold or leak of chemical substance can have serious human, economic and ecological impacts.

Thanks to our connected telemetryYou can control your tank levels in real time, anticipate anomalies and centralize all your critical data. Whether you’re monitoring a gas tank, H224 or H225 products, or liquid effluents, you’ve got the right solution. reliable, scalable and scalable system control your risks (fire, explosion, pollution…).

Find out how our technology contributes to 6 VR control while ensuring traceability and compliance with ICPE compliance industrial performance of your installations.

Why monitor tanks on an ICPE or SEVESO site ?

Understanding the challenges: safety, compliance, environment

On an ICPE or SEVESO classified site, the management of industrial tanks leaves no room for improvisation. A storage facility for chemical substances or petroleum products presents a particular risk. risk risk ofemissionof pollutionor evenexplosion. Visit treatment of these risks requires a reliable reliable measurement systemcapable of transmitting information real-time information on levels liquid levels flowsor temperature or pressure thresholds.

What is an ICPE or SEVESO site?

An ICPE (Installation Classée pour la Protection de l’Environnement) refers to any industrial industrial activity likely to emit hazardous substances or generate an impact on the impact on the environment. These installations are subject to strict regulations because of the risks related to their operation: fire, explosion, chemical chemical productswater or air pollution.

Visit SEVESO sitesThese are ICPEs subject to stricter obligations, due to the volume or nature of the substances stored (classified as H224, H225, etc.). They must implement technical provisionstechnical emergency plans and rigorous monitoring of tank levels.

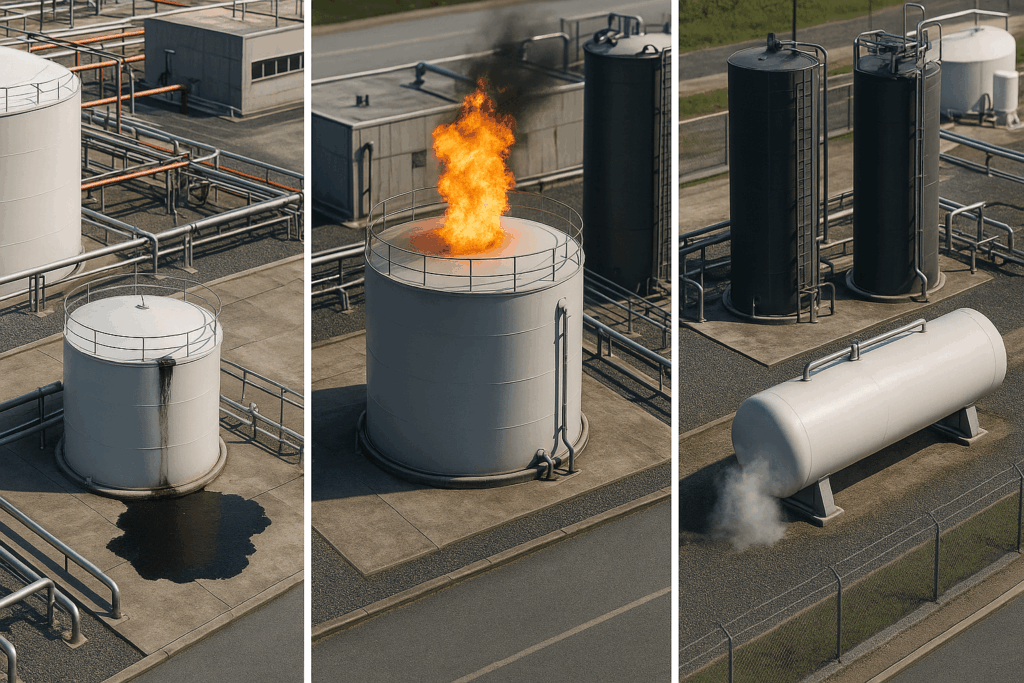

Risks associated with poor reservoir management

No reliable measuring systemindustrial tanks and vessels present a number of hazards:

🔥 Fire or explosion In the event of overfilling or accumulation of flammable gases, particularly on products classified as H224 / H225.

🌍 Soil and water pollution undetected leakage or spillage of effluents or toxic substances

💨 Hazardous substance leak: uncontrolled emissions impacting operators and the immediate environment

Key figures

According to Ineris, nearly 60% of incidents reported at SEVESO sites since 2020 are linked to failure to monitor or maintain of storage equipment.

Regulatory requirements (ICPE / SEVESO decrees)

Operators of ICPE and SEVESO sites must comply with a series oftechnicaladministrative and environmental requirements:

- Installation of an automated measurement system and real-time level monitoring

- Data recording (stocks, thresholds, volumes) for control by authorities

- Detection of anomalies (leakage, overpressure, critical level) with immediate transmission

- Prevention plans for hazardous products, particularly highly flammable liquids

- Monitoring of indicators relating to 6 RV Risks: fire, explosion, pollution, substances, environment, human

Comparison table

| Regulatory requirements | How our solution meets them |

|---|---|

| Tank level monitoring (Art. July 1, 2004, Order 2020) | Radar or pressure sensors, integrated into our platform |

| Control of products classified as H224/H225 | Specific detection and critical threshold alert |

| Measurement history / ISOPE traceability | Automatic archiving on secure server |

| Risk management (6 RV) | Indicators integrated into the Four Data dashboard |

| Inspection & regulatory audits | One-click report generation and export |

🔗 Official references :

Légifrance – ICPE order of April 21, 2005

Order of July 1, 2004 – storage of hydrocarbons

SEVESO III Directive – EUR-Lex

Our connected telemetry solution

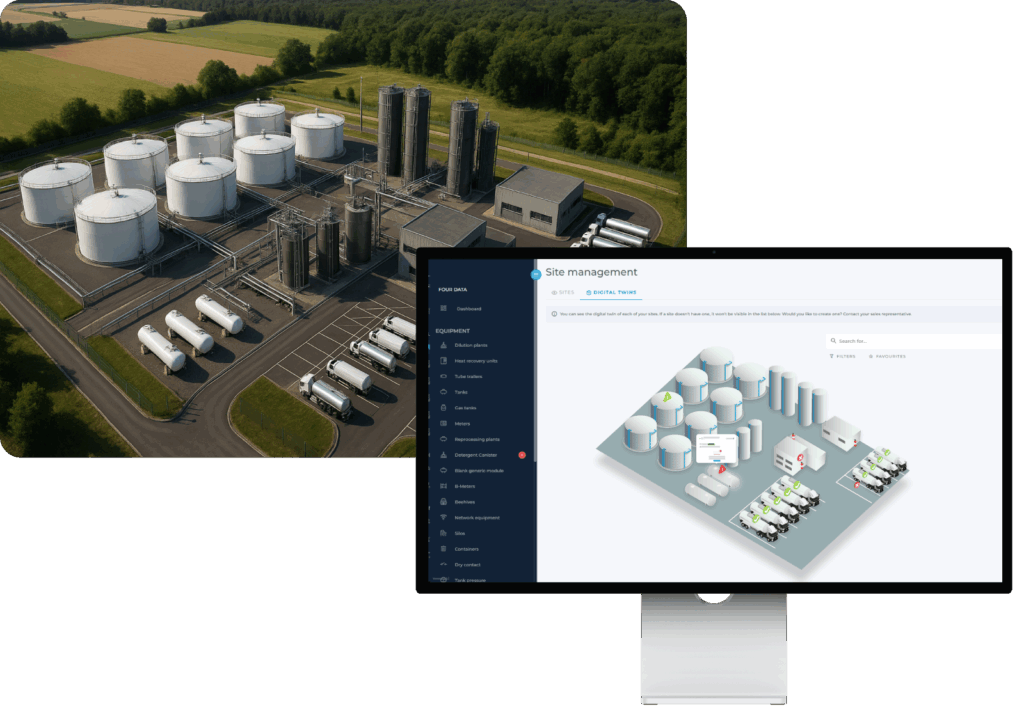

Real-time monitoring and data visualization

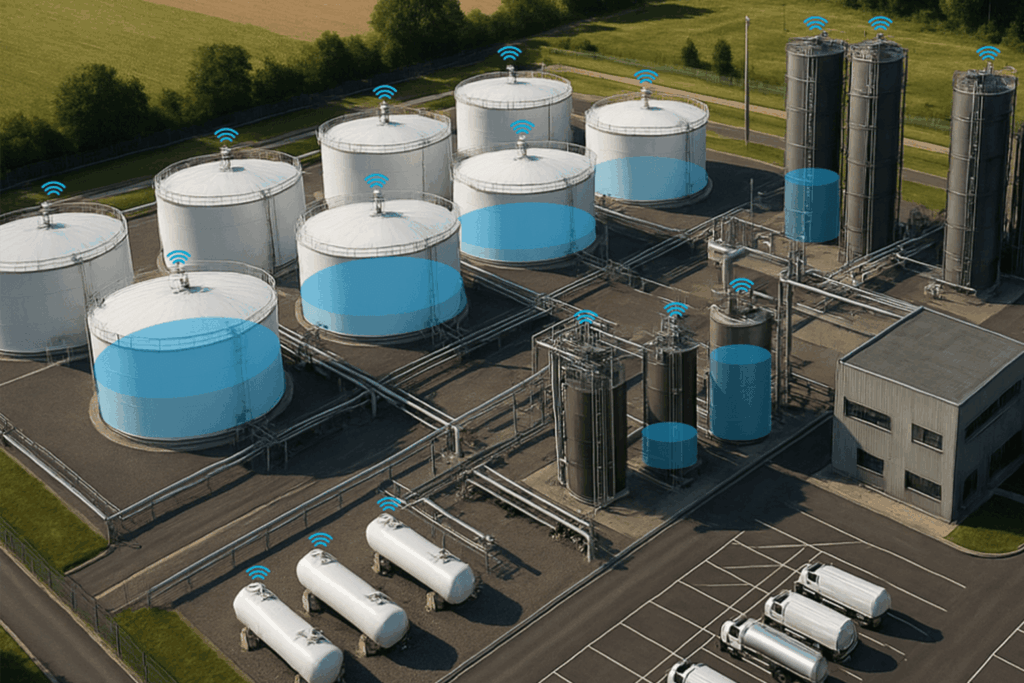

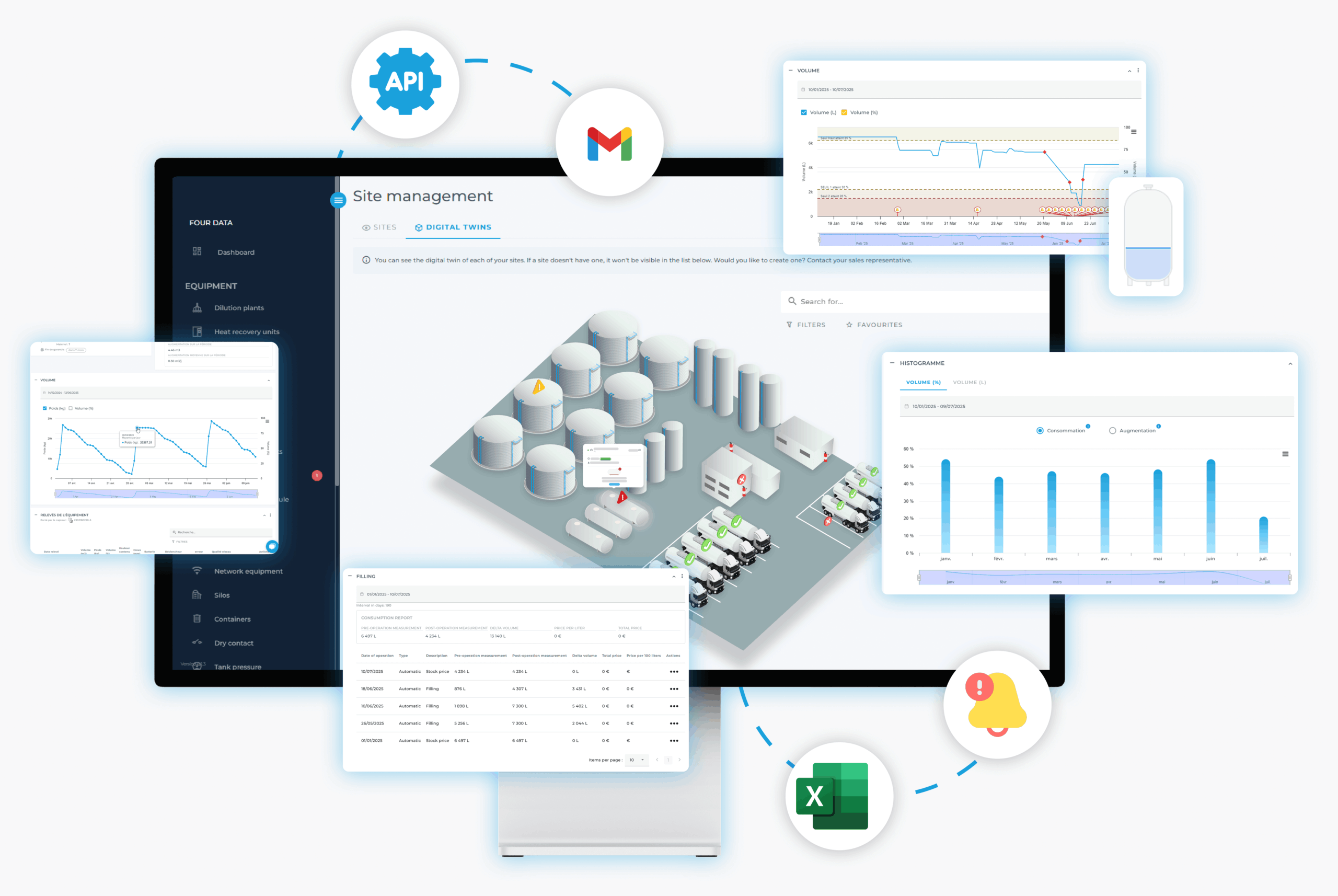

Our telemetry system enables continuous continuous measurement of your tanks, cisterns and reservoirs, regardless of the type of type of substance stored (flammable liquid, effluent, chemical product). The data is automatically transmitted to our cloud platform, which can be consulted via web interface and mobile application or on a local display.

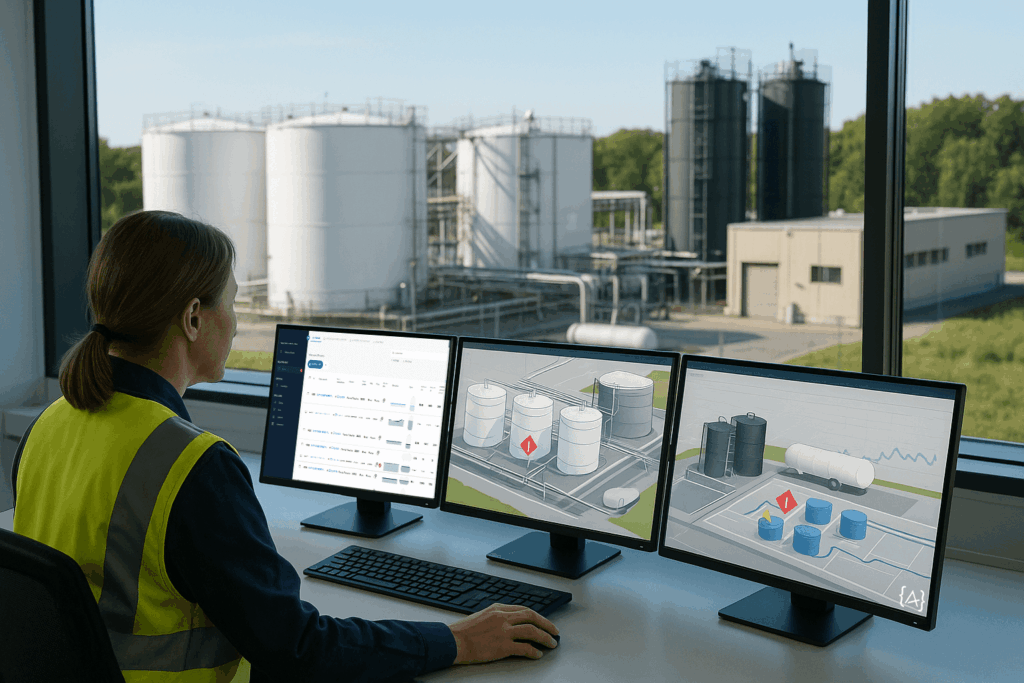

In just a few clicks, operators can visualize the status of each installationwith values updated every X minutes (depending on the package chosen, between 2 and 5 minutes). A precise digital twin map of the site allows you to visually locate the equipment under surveillance, as well as any ancillary equipment (fire extinguishers, trucks, etc.).

Smart alerts, thresholds and incidents

Our sensors automatically trigger intelligent alerts as soon as a critical threshold is reached: level too low or too high, abnormal variation, suspected leak or overpressure.

These alerts are contextualized and can be transmitted via email, SMS or push notificationaccording to your preferences. Thanks to our rules engine, you can configure customized scenarios by tank type, stored product or risk zone.

Intelligent features :

- Detection of threshold exceedance

- Immediate notification to safety manager

- 12-month alert history

- Coupling with local automation(pump stop, valve closure)

History and full traceability

All the measurements are archived securely to ensure traceability of your tank levels over time. You can view historical values by product, plant or period (day, month, year).

Our platform also allows you toexport data in PDF or Excel format, to meet regulatory requirements or document ICPE/SEVESO inspection reports.

Sensors and connectivity (NB-IoT, LTE-M, Radar, etc.)

We offer several sensor technologies depending on the characteristics of the site nature of the productthe level of precision required and thenetwork environment (urban, rural, sensitive site).

| Sensor | Frequency / Time / ATEX / Network |

|---|---|

| Millimeter radar | Every 30 min / 10 years / ATEX Zone 0 / NB-IoT, LTE-M |

| Hydrostatic pressure | Every 15 min / 7 years / ATEX Zone 1 / Sigfox, Lora, NB-IoT, LTE-M |

| Reinforced ultrasonics | Parameterizable / 5 years / Non ATEX / Sigfox, Lora, NB-IoT, LTE-M |

| Valve position sensor | Real-time position / 1-8 years / ATEX / LoRaWAN, class A, EU and USA |

🌐 Networks available by zone :

- LTE-M / NB-IoT: industrial zones, wide coverage

- Sigfox/ Lora: wide coverage, low power consumption

- Private gateway: dedicated local deployment

Integration with the Four Data IoT platform

All the data collected by the various sensors is visualized on our centralized IoT platformbuilt for manufacturers. It brings together all the essential building blocks for unified management :

- Collect data from your multi-protocol sensors

- Analysis measurements, thresholds, behavioral deviations

- Alert in case of drift or incident detection

- Valuation via dashboards, digital twins and reports

The system is interoperable with existing PLCs, SCADA systems or ERP systems.

A range of solutions for efficient management of your ICPE / SEVESO sites

The management of tanks and reservoirs on ICPE or SEVESO classified sites cannot be limited to simple manual records. Regulatory constraints, the risk of incidents (fire, explosion, pollution) and the need for complete traceability call for reliable, intelligent and interoperable tools.

With Four Data, you get a complete industrial telemetry solution, combining :

- Multi-technology connected sensors for sensitive environments and ATEX zones.

- Secure IoT connectivity (NB-IoT, LTE-M, LoRa, Sigfox, private gateway).

- A centralized IoT platform, interoperable with your SCADA/ERP systems, guaranteeing unified control.

- Intelligent alerts, configurable according to critical thresholds and risk scenarios.

- Regulatory traceability in compliance with ICPE decrees and the SEVESO III directive.

How it works: From sensor to data

Turnkey solution – Four Data installation & support

✔️ A complete offer, from delivery to commissioning :

- On-site installation anywhere in France and Europe by our specialized technicians.

- Initial configuration (sensors, thresholds, IoT connectivity, platform integration).

- Functional testing and validation under real-life conditions.

- Rapid team training for immediate familiarization.

✔️ Robust, durable equipment :

- Certified level sensors (radar, pressure, ultrasonic, etc.), selected according to your application.

- Suitable fasteners (clamps, stainless steel plates, dedicated brackets).

- IP68 waterproof industrial enclosure, designed to withstand the most demanding environments.

- Long-life battery (up to 5 to 10 years’ autonomy, depending on model).

- For certain models: no-drill installation, fast and without production downtime.

✔️ Ongoing support from our CS teams :

- Getting to grips with interfaces (web dashboard, mobile application, digital twin).

- Plug-ins and upgradeable modules to adapt the platform to your business needs (ERP, SCADA, local automation).

- Reactive customer support (SAV): remote assistance or rapid field intervention.

- Software updates included to guarantee performance and regulatory compliance.

What our users say

Discover below authentic customer feedback, focused on the concrete benefits seen with our water level sensors for tanks:

⭐️ Average rating: 4.8/5 (internal estimate based on regular customer feedback)

Customer testimonials

Concrete benefits: Optimized management of high-risk sites, combining operational efficiency and regulatory control.

Thanks to the Four Data connected solution, we’ve been able to automate the monitoring of our tanks and trigger collections at the right time, without any intervention from our customers. This reduces the risk of overflow and improves safety at our sites. On a day-to-day basis, this represents a real gain in operational efficiency and environmental compliance.

Concrete benefits : ease of use, centralized data, instant alerts to avoid incidents.

Why choose Four Data for your ICPE / SEVESO projects?

Expert support, from understanding the field to industrializing your solution

📍 Monitoring a SEVESO or ICPE tank is more than just installing a sensor. At Four Data, we integrate the entire IoT chain – sensor, connectivity, platform, data – to guarantee secure, compliant and interoperable monitoring.

Studio

Impulse

Service

FAQs

Contact & demonstration

Make an appointment with an expert

Do you have a project in progress or a specific problem on an ICPE or SEVESO site? Our technical teams are at your disposal to support you every step of the way.