IoT Sensors: How They Work

Introduction – What is the IoT?

The Internet of Things (IoT) refers to all physical objects capable of collecting, transmitting and receiving data via the Internet. These objects, equipped with sensors and communication modules, enable continuous interaction with their environment, facilitating automated or assisted decision-making. IoT sensors represent a major technological advance in many fields, including industry, agriculture, logistics, energy and health.

According to a 2024 McKinsey report, the IoT could generate up to $12.6 trillion in economic value annually by 2030, driven by its wide range of high-impact applications (McKinsey).

In industrial and energy infrastructures, IoT sensors play a central role: they monitor stocks, optimise maintenance and reduce energy losses. In this way, the IoT is transforming operating models, making them more responsive, economical and sustainable.

1. What is an IoT sensor?

An IoT sensor is a device that measures physical data (such as temperature, humidity, pressure, level or movement) and transmits it to an analysis system via a wireless connection. It is designed to operate autonomously over long periods, even in harsh environments.

Unlike a traditional sensor, the IoT sensor is connected to a network that enables it to communicate with other machines or cloud platforms. It is therefore part of a logic of interoperability between intelligent objects. The data collected is structured and analysed to trigger alerts, predict needs or automate specific tasks.

In the energy sector, IoT sensors can measure fuel levels in tanks, avoiding stock-outs or costly over-filling.

In short, an IoT sensor does more than simply measure data: it is part of an intelligent chain of information processing serving operational performance.

2. The key components of an IoT sensor

An IoT sensor works by integrating a number of essential components, each of which plays a decisive role in the measurement, processing and transmission of data.

The physical sensor

This is the element that interacts directly with the environment. It detects precise physical phenomena: temperature, pressure, luminosity, liquid level, vibration, etc. For example, in a fuel oil tank, an ultrasonic or radar level sensor measures the distance between the sensor and the surface of the liquid.

The microcontroller

This component acts as the brain of the device. It collects the raw data from the physical sensor, processes it and converts it into usable data. It can also perform basic calculations or make simple decisions, such as triggering an alarm if a value exceeds a defined threshold.

The communication module

It transmits data to a remote platform. Several types of communication are used depending on requirements: LoRaWAN, Sigfox, NB-IoT, LTE-M, 4G/5G or Wi-Fi. LPWAN (Low Power Wide Area Network) networks, such as LoRaWAN or Sigfox, are particularly well suited to IoT sensors, as they offer long autonomy and long-distance transmission with low energy consumption.

Power supply of IoT sensors

An IoT sensor is generally battery-powered, with autonomy ranging from several months to several years. Some are also solar-powered or connected to a fixed power source. Energy efficiency is crucial to ensure the durability of the device.

So the smooth operation of an IoT sensor depends on the harmony between these components. Their quality, compatibility and adaptation to the environment in which they are used determine the reliability of the measurements and the overall performance of the IoT system.

3. How is the data transmitted?

The process of transmitting data from an IoT sensor follows a well-defined chain. Once the data has been captured by the physical sensor and processed by the microcontroller, it is converted into a digital signal. This signal is then transmitted via the communication module using a protocol adapted to the context.

LPWAN protocols such as LoRaWAN and Sigfox are preferred where sensors are remote or deployed in rural areas. These networks offer a long range (up to several tens of kilometres) with low energy consumption. Technologies such as NB-IoT or LTE-M, which are based on cellular networks, offer higher bandwidth, suitable for sensors transmitting larger volumes of data.

Once the data has been transmitted, it is received on a secure server or cloud platform. These platforms, often accessible via a web interface or mobile application, enable data to be viewed, alerts to be configured and automated reports to be generated. It is also at this stage that data analysis can be enhanced by machine learning algorithms to detect trends, anticipate anomalies or trigger corrective action.

This entire transmission architecture forms the backbone of modern IoT systems. It ensures that the information collected by the sensors flows smoothly, securely and in a way that can be exploited.

4. What does it actually do?

IoT sensors are now used in a multitude of industries, and their impact is particularly visible in sectors where monitoring, maintenance and energy performance are critical.

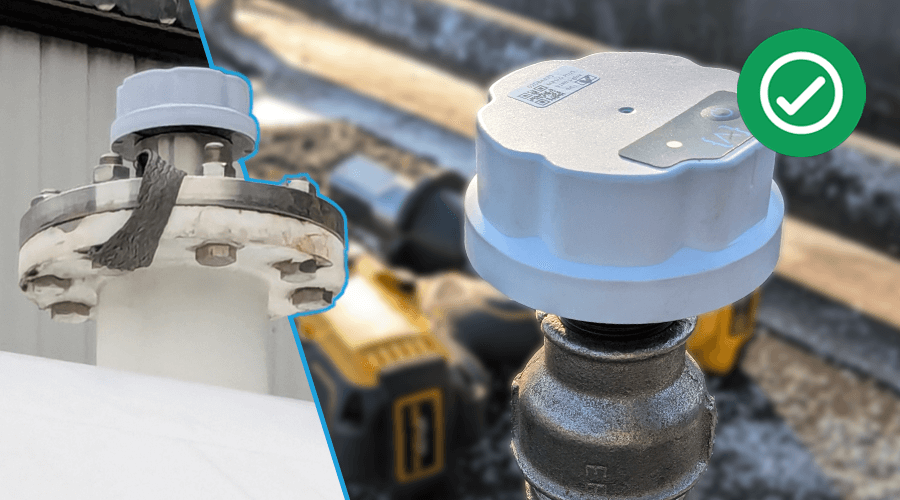

Tank monitoring and stock management with IoT sensors

In the fuel and food sectors, IoT sensors measure liquid levels in tanks. The data can be used to monitor stock levels, anticipate replenishments and avoid stock-outs or overflows. This automation reduces logistics costs and improves responsiveness.

Monitoring temperature and environmental conditions

In cold logistics or pharmaceutical laboratories, sensors measure temperature, humidity or light. This ensures compliance with preservation standards and prevents sensitive products from deteriorating.

Predictive maintenance in industry

Sensors monitor vibrations, pressure or machine operation. By analysing this data, maintenance managers can intervene before a breakdown occurs, extending the life of equipment and reducing unscheduled downtime.

Energy management and operational performance

IoT sensors can also be used to measure energy consumption in buildings or on production lines. They help to identify the most energy-intensive items and implement targeted reduction measures.

5. Focus on Four Data’s IoT sensors

Four Data develops and deploys IoT solutions specially designed for intelligent resource management in the energy, agriculture and industry sectors. Its approach is based on the integration of robust, autonomous sensors with data processing and analysis platforms. The sensor automatically sends data to an online interface, where users can view levels, set alerts and plan deliveries.

Four Data also uses appropriate communication technologies, such as Sigfox and LTE-M, to ensure that sensors are always connected, even in areas with poor coverage.

In addition to the hardware, Four Data offers a software suite for analysing the data collected, displaying consumption trends and creating customised reports. These tools enable companies to optimise their logistics flows, better anticipate needs and reduce operating costs.

In this way, Four Data is positioning itself as a strategic player in the digital and energy transition, providing practical, proven solutions for intelligent, sustainable resource management.

Conclusion

IoT sensors are profoundly transforming the way businesses collect, analyse and exploit data. From simple measurement devices, they have become central elements in the digital strategy of industries, enabling more precise, faster and more sustainable management of resources.

Thanks to a detailed understanding of the technologies, optimised integration and concrete use cases, IoT sensors are playing an active role in modernising infrastructures. And with solutions like those offered by Four Data, their impact extends far beyond simple measurement, becoming a lever for competitiveness and innovation.

Check our last article.

You may also be interested in these articles :