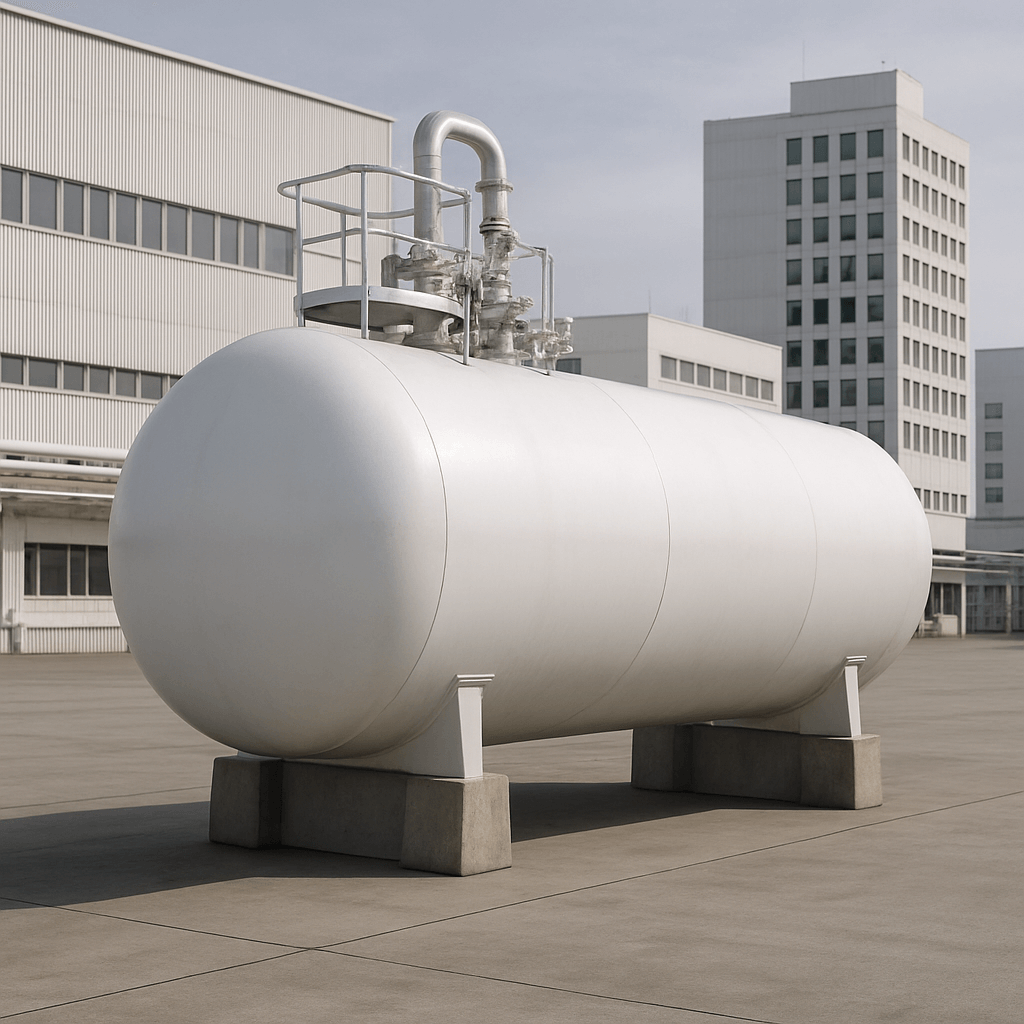

Connected LPG telemetry sensor: Remote LPG monitoring to prevent breakdowns

Do you manage propane / butane deliveries or are you responsible for a fleet of LPG tanks? Our connected gas gauges transform your approach into a predictive predictive telemetryfor remote remote monitoring of gas levelsautomated planning and a measurable reduction in logistics costs. Thanks to our connected sensors compatible with mechanical gaugesWith our mechanical sensors, you can eliminate emergencies, control filling and reduce emissions.

📘 Discover our free white paper:

Find out how VMI propane / butane (Vendor Managed Inventory) enables distributors like Antargaz to reduce their kilometers driven by 18% and their CO₂ emissions by 12%.

TABLE OF CONTENTS

- Why choose a connected gas gauge?

- How a connected gauge works: from sensor to data

- Benefits of VMI control with connected gauge

- Case study: Antargaz optimizes propane logistics with Four Data

- Our range of connected gas gauges

- Our IoT platform to add value to your data

- What is the return on investment of a connected gauge?

- Complementary solutions for the gas industry

- Application sectors: where to install our connected gauges?

- Why choose Four Data?

- Launch your connected LPG project with Four Data 🚀

- FAQ : Tank level gauges and sensors

Why choose a connected gas gauge?

The challenges of level management in silos or other storage facilities (liquid or solid) are numerous. Accurate monitoring of level measurement in facilities is essential to avoid stock-outs or unnecessary surpluses, which can lead to additional costs and disruptions in the supply chain.

Anticipate breakdowns and guarantee continuity

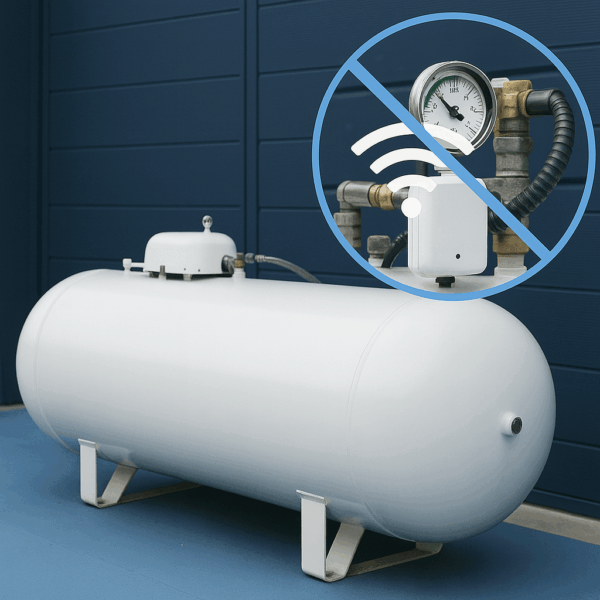

Conventional mechanical gauges require unreliable manual readings, especially on underground tanks or those located in hard-to-reach areas. As a result, gas ruptures are frequent, with immediate consequences for customer operations, logistics and the environment.

With a connected gas gauge, you can automate tank level monitoring, benefit from regular feedback and activate alerts before any critical threshold.

✅ Here are the critical situations you avoid:

- LPG rupture in private homes (heating, cooking, hot water)

- Line stoppage or loss of production on an industrial site

- Emergency deliveries to €150-200 per job

- Disorganized tours and increased stress for planners

- Over-consumption of fuel due to non-optimized journeys

- Over-emissions of CO₂ due to empty or lightly loaded trucks

Optimize your deliveries and cut costs

By replacing manual management with remote monitoring of gas levels, connected sensors avoid unnecessary rounds and half-filled tanks. A data-driven filling strategy (VMI propane / butane) considerably increases the loading rate of trucks, while reducing the number of kilometers driven.

For example:

A distributor makes an average of 10,000 deliveries a year.

By optimizing planning, each delivery increases the average fill rate from 45% to 70%.

Since the unit cost of a drop is estimated at €65, savings exceed €230,000/year, excluding avoided emergencies.

Before / After connected sensor (average fill rate)

Before sensor ▓▓▓▓░░░░░░ 45%

After sensor ▓▓▓▓▓▓▓▓░░ 70%

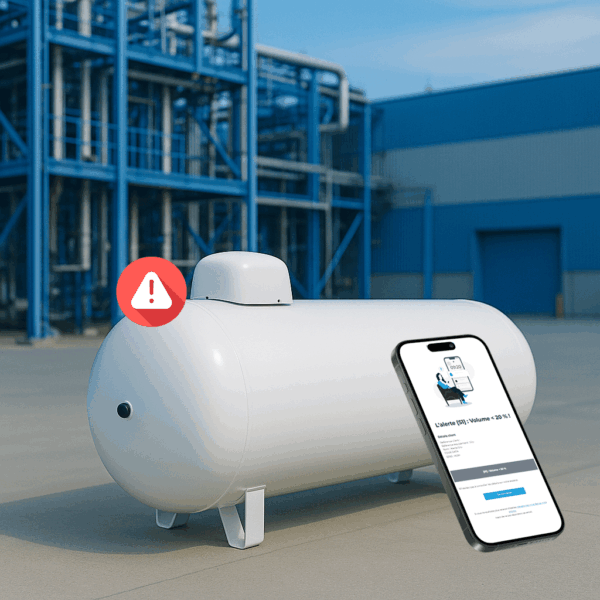

Secure your facilities with intelligent alerts

Connected gauges don’t just measure: they actively monitor your tanks and trigger alerts in the event of an abnormal situation.

Available alerts include :

- Critical low level: anticipation of control thresholds.

- Suspicious leak: alert in the event of a rapid drop in level without delivery.

- Abnormal behavior or drift: monitoring of non-compliant filling or consumption.

🎯 Example of use:

In a propane service station, an abnormal drop alert identifies a valve fault before any incident occurs. At an industrial site, a threshold alert prevents a break in supply over the weekend, and automatically triggers an order via the connected ERP system.

How a connected gauge works: from sensor to data

On-board technologies: pressure, ATEX…

The Four Data connected sensors adapt to the majority of mechanical gauges on the market, with no need to modify the reservoir. Designed for rapid, robust installation, they are based on proven technologies that guarantee reliability, safety in ATEX zonesand measurement accuracy.

🔧 Extended compatibility :

Our sensors are compatible with the most popular models, including Rochester (Magnetel Junior/Senior 4″/8″)Cotrako, Rotarex SRG, Cavagna, Sakae Seiki, GOK or Krueger Sentry Gauge.

🧪 Comparative table of on-board technologies :

| Sensor | Typical use | Key benefits |

|---|---|---|

| Pulse | Connected meter | Gas consumption monitoring via dry contact pulse inputs. |

| Pressure | Pressurized tanks | High precision and robustness |

| Ratiometric | Pressurized tanks | Hall effect probe, direct reading on Rochester gauge, optimum accuracy |

💡 Please note All our sensors are designed for long-term use (>5 years)!

Transmission via IoT networks (NB-IoT, LTE-M, Sigfox, etc.)

Once installed, the connected gauge transmits gas level data to our platform via low-power IoT networks. These networks are chosen according to available coverage and site environment.

📡 Protocols used :

- NB-IoT excellent indoor penetration, ideal for underground tanks

- LTE-M for extensive coverage and low latency, perfect for industrial areas

- LPWAN/Sigfox very low power consumption, suitable for rural areas

🛠️ Benefits :

- Autonomous transmission without human intervention

- Low energy consumption

- Real-time data security even in remote areas

📲 Illustration to be provided Protocol pictograms + coverage map

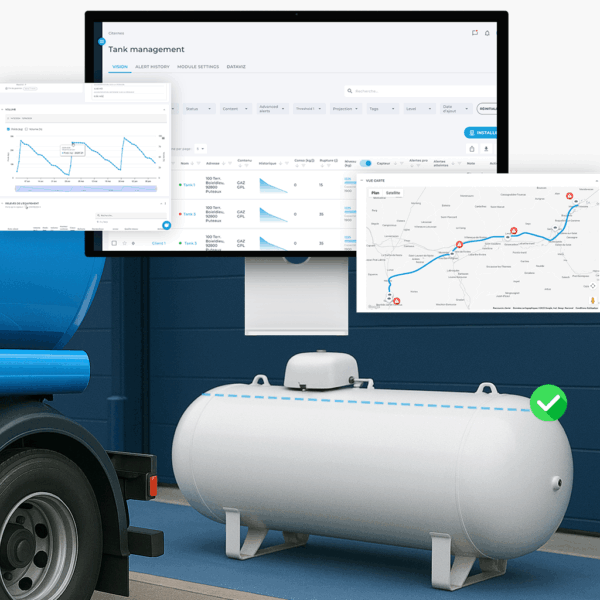

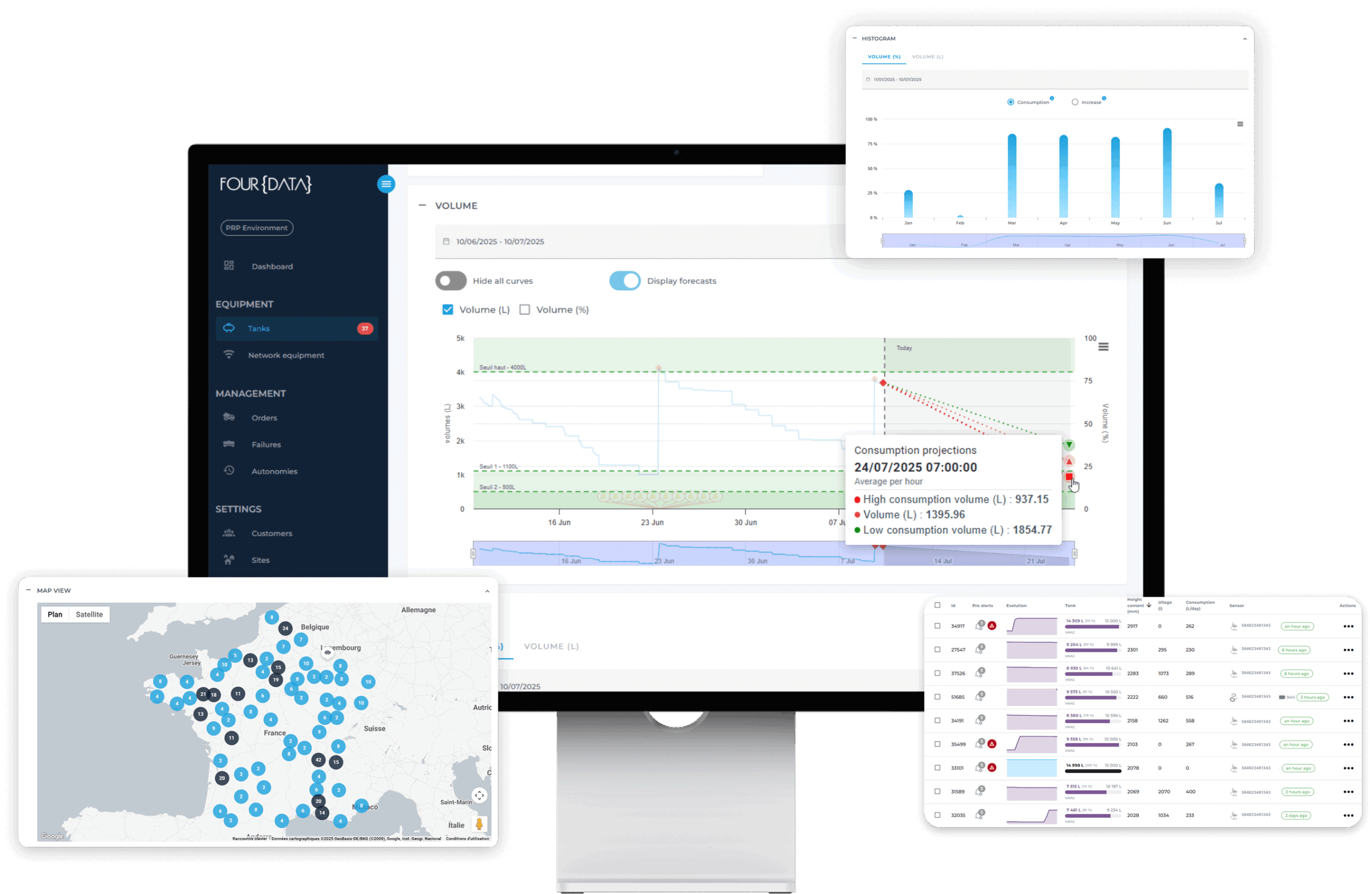

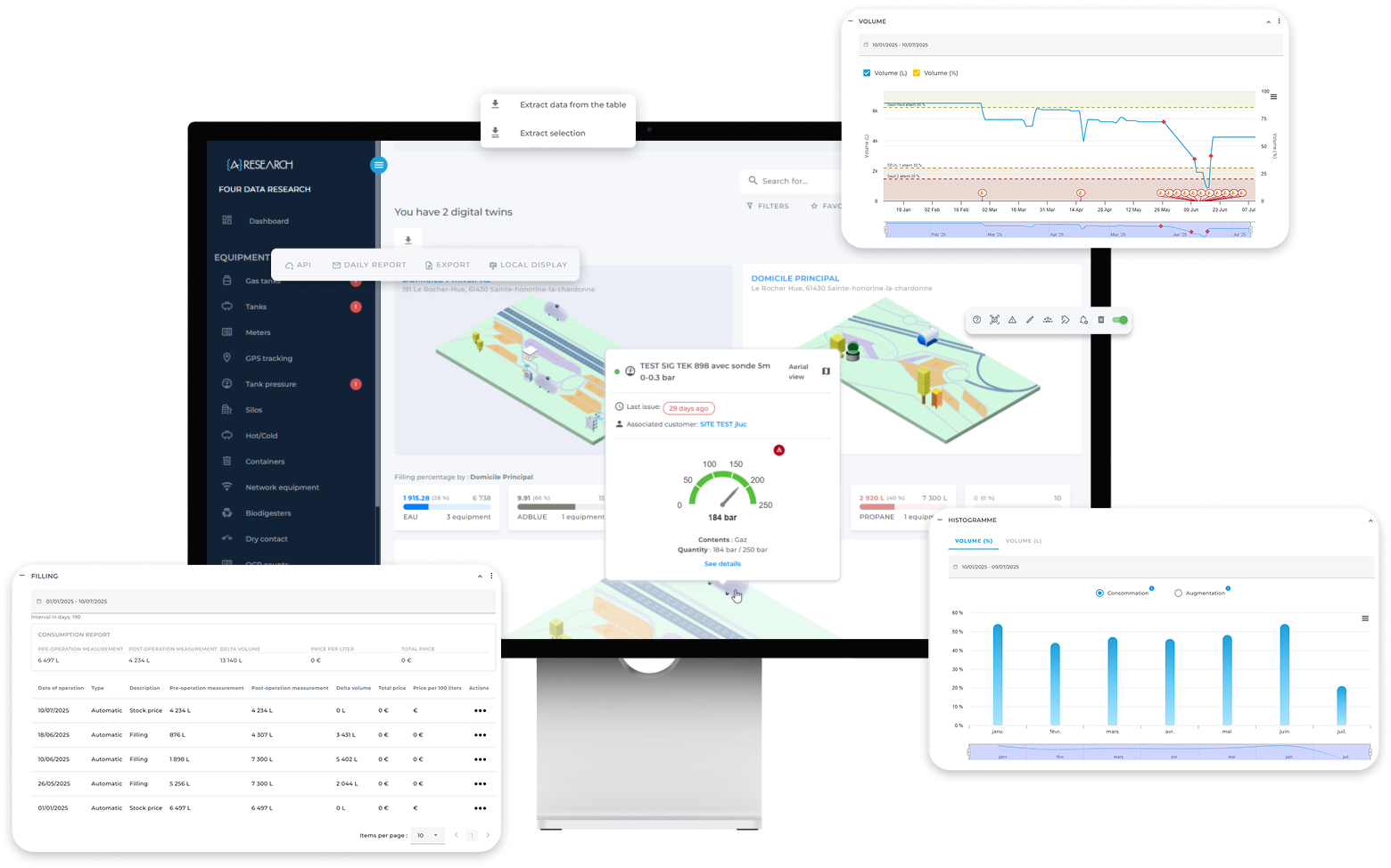

Live visualization on our modular software platform

All data collected is centralized in a secure SaaS interface (ISO 27001), accessible via computer or mobile. Our multi-sensor platform enables you to control hundreds of tanks simultaneously, with a consolidated view.

🧩 Key features :

- Remote monitoring of gas levels, consumption history

- Configurable alerts (thresholds, drifts, inactivity, etc.)

- API/FTP integration to your tools (ERP, TMS)

- Advanced modules :

- Prediction of rupture date (IA – <5% MAPE)

- Automatic generation of sales orders

- Synchronization with EVMI modules for financial inventories

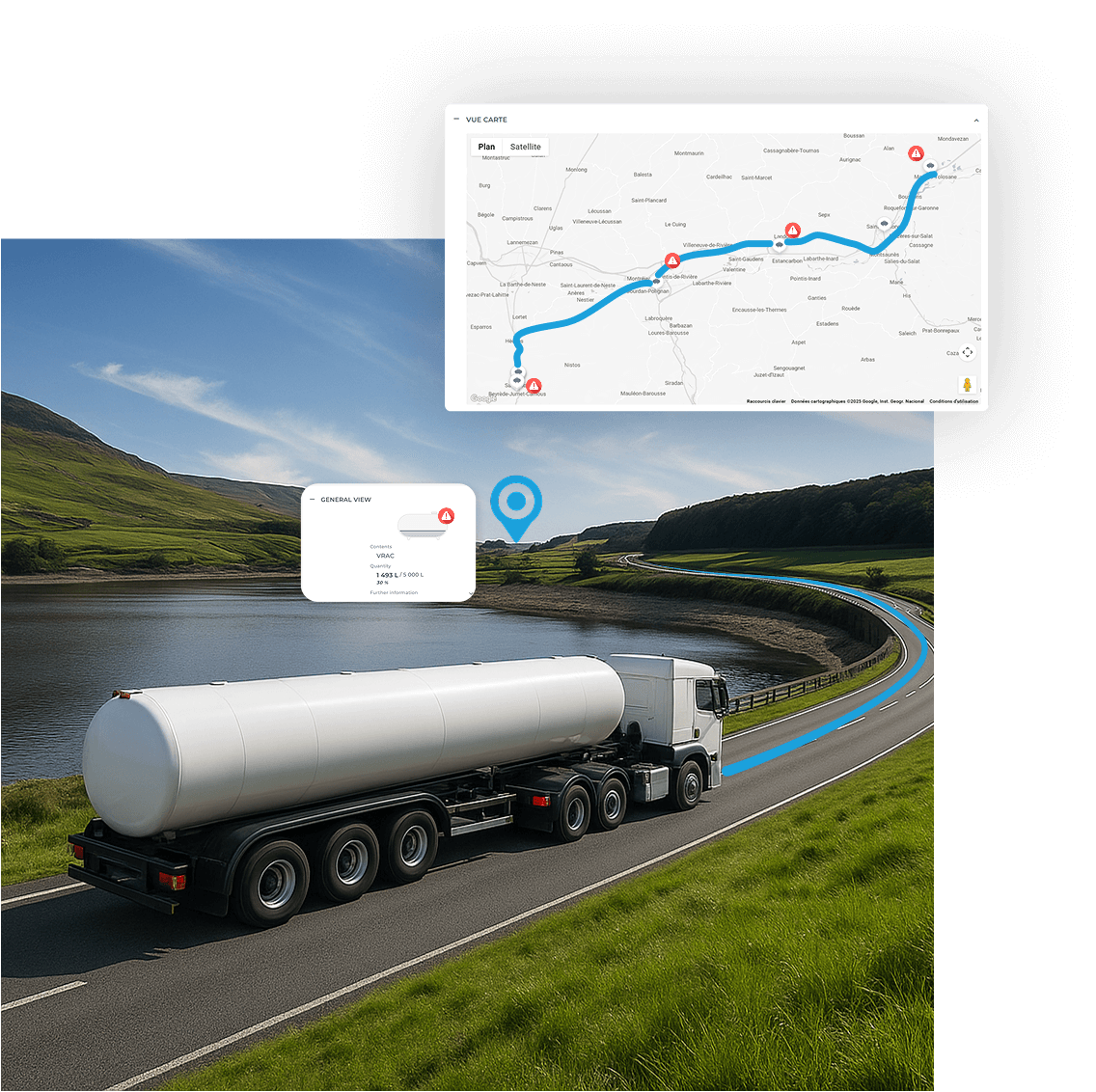

Benefits of VMI control with connected gauge

The combination of a connected propane / butane gas gauge with a VMI (Vendor Managed Inventory) transforms logistics into an intelligent, predictive and profitable system. This model enables distributors to regain control over planning, while offering a differentiated service to the end customer.

1 For the distributor: from submissive touring to controlled logistics

Adopting a connected VMI model enables you to every delivery into an optimized decisionbased on actual tank levels, rather than estimates or customer calls.

The logic is changing: we’re moving from a “reactive” model (customer call → delivery) to an automated, data-driven model. automated, data-driven modelwhere the platform proposes the ideal tour, in real time.

2Forthe customer: less worry, more comfort

With propane/butane remote reading integrated into the VMI, the customer doesn’t have to do a thing Their gas level is automatically monitored, and delivery is anticipated without human intervention.

Case study: Antargaz optimizes propane logistics with Four Data

By 2023, Antargaz, one of France’s leading LPG companies, has chosen to equip more than 6,000 propane/butane tanks with Four Dataconnected gauges, as part of a nationwide rollout focused on strategic customers: industrial companies, condominiums and farmers.

✅ Operational results after 12 months are indisputable:

- -18 % kilometers travelled, for equivalent delivery volumes

- -12 % CO₂ emissions per tonne delivered

- ROI less than 9 monthsincluding hardware and installation

This deployment was accompanied by API integration with Antargaz’s internal tools, as well as support in the field for tank segmentation, setting reminder thresholds, and training planners.

example of equipable materials

Our IoT platform to add value to your data

Alerts, dashboards, data export

Our SaaS platform Desk & Sens gives you access to a comprehensive, intuitive supervision cockpit. Thanks to the data continuously collected by our connected sensors, you can monitor your tanks in real time.

🛠️ Available features :

- Customizable alerts :

- Level thresholds (min, max, fast fall…)

- Notifications by email, SMS or push

- Escalation scenarios: planner → technician → management

- Multi-site dashboards :

- Visualization of levels in % or liters

- Sensor status (battery, signal, anomalies)

- Interactive plant map

- Exports & reporting :

- Downloadable data in CSV, Excel, JSON

- Automatic export to corporate IS

- Long-term archiving for traceability

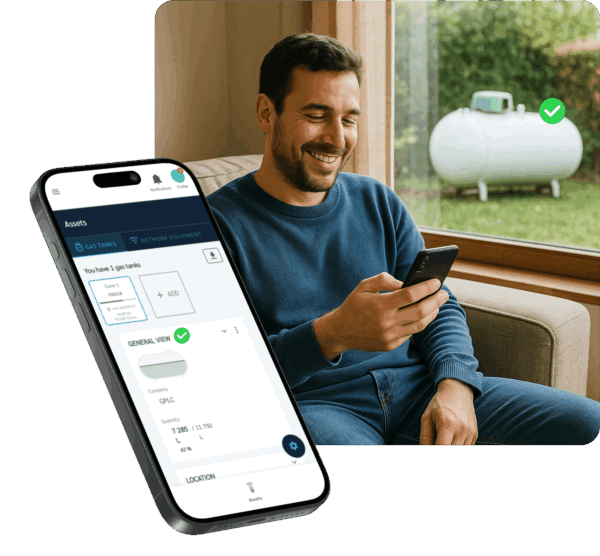

Mobile application and customized interface

Whether in the office or on site, the platform is accessible on smartphonetablet or PC. L’ dedicated mobile application provides quick access to consumption levels, alerts and history.

🎯 Advantages for the field user :

- Immediate reading of tank level

- Warning of impending rupture

- Site monitoring without having to travel

🖌️ The interface is also customizable to your corporate colorsThe interface can also be customized with your company’s colors, so that it can be adopted by your internal teams or end customers (resellers, partners, etc.).

API connection to your existing tools

Our IoT platform integrates easily into your IT ecosystem, thanks to REST APIs documented and secured. For more complex industrial applications or constrained environments, a MQTT gateway is also available.

🔗 Examples of frequent connections :

- ERP : SAP, Oracle, Odoo

- TMS : Antargaz IS, OptiFlow, Transporeon

- CMMS : Mobility Work, Carl Source

- BI : Power BI, Qlik Sense

This connectivity ensures automated data flow between the connected gauges, your planning tools, and your financial services (EVMI).

What is the return on investment of a connected gauge?

Invest in a connected propane gas gauge is more than just an operational convenience: it’s a rational, quantified and measurable decision.

On average, a delivery of LPG costs €65. By improving tour fill rates from 45% to 70% and eliminating unnecessary or urgent deliveries, a distributor with 10,000 deliveries a year can save up to 232,000 per year – on direct costs only. Added to this are reductions on :

- Fuel consumption,

- CO₂ emissions,

- Customer management fees,

- And logistical penalties.

⏱️ ROI observed: less than 9 monthsincluding hardware and installation.

📊 Calculate your ROI in just a few clicks :

We provide you with an interactive matrix allowing you to simulate your own savings according to your volume of activity, the cost of your rounds, and the number of tanks to be equipped.

They trust us:

Complementary solutions for the gas industry

Discover our 3 connected solutions to transform your gas inventory management into a simple, precise and environmentally responsible process:

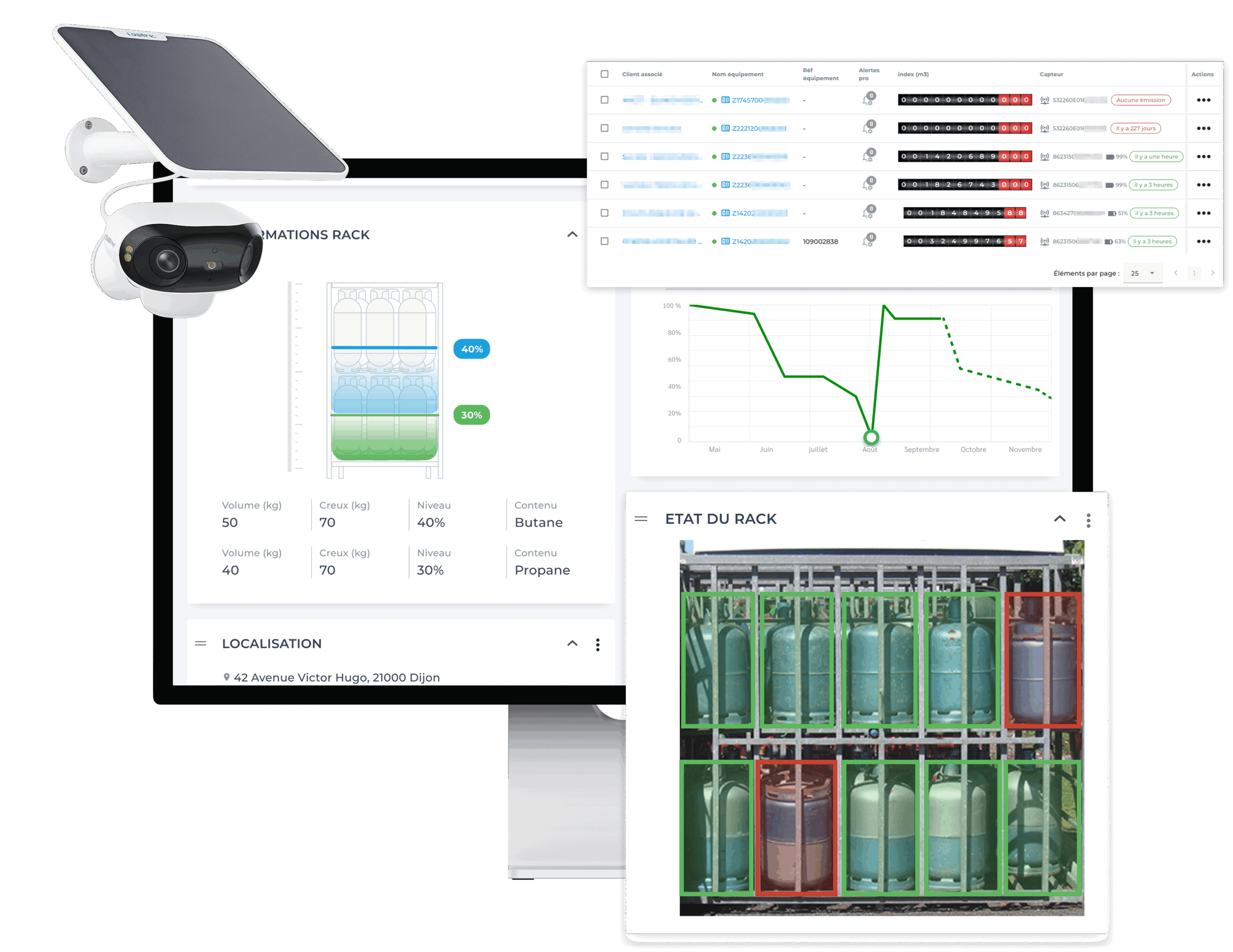

GAS RACK: COMPUTER VISION

An on-site camera captures images at regular intervals and, thanks to dedicated artificial intelligence, identifies your full or empty bottles in real time. You benefit from instant alerts, total remote visibility and automatic optimization of your replenishments – with the option of satellite photo tracking to take things even further.

CONNECTED CAPACITIVE PROBE

Equip your cylinders with intelligent capacitive sensors and monitor their levels continuously from a centralized platform. Benefit from ultra-precise measurements, proactive alerts on low levels, and avoid service disruptions thanks to early replenishment.

Application sectors: where to install our connected gauges?

Depots and service stations (petrol, propane…)

In depots and service stations, gas availability is critical. A poorly anticipated level can lead to a supply disruption, bringing business to a standstill.

Our connected propane gas gauge provides continuous supervision of each tank, with automatic triggering of deliveries via VMI.

✅ Case study On a multi-tank site, the platform detects a consumption drift on a propane fuel tank, triggering an advance order and avoiding a service interruption.

Hydrogen: managing sensitive tanks

Hydrogen requires a high level of safety and precision. Vessels may be insulated or subject to strict ATEX protocols.

Our ATEX Zone 1 connected sensors guarantee reliable safe and reliable monitoringwithout direct contact with the fluid, to reduce the risk of manual intervention.

✅ Case study A chemical manufacturer uses the Four Data pressure sensor to supervise its hydrogen tanks feeding a production line, with multi-level alerts configured.

Industry & Logistics: multi-site supervision

Logistics sites, workshops or warehouses equipped with LPG tanks require coordinated coordinated between several sites. The lack of a centralized vision complicates planning.

The Four Data platform enables multi-site managementwith shared access between operators and logistics management.

✅ Use cases Logistics: a fleet of warehouses in 3 countries benefits from a consolidated dashboard. The logistics department visualizes levels and prioritizes inter-site rounds from a single tool.

Agriculture: gas tanks in rural areas

In the agricultural sector, propane or fuel oil tanks are often isolated, buried or difficult to access. Farmers lack the time to check them manually.

Our connected sensors ensure autonomous monitoringwith SMS/email alerts, even in areas with poor coverage, thanks to NB-IoT or LTE-M networks.

✅ Use cases A CUMA (Coopérative d’Utilisation de Matériel Agricole) in Burgundy monitors the level of its shared tanks remotely, and receives an alert as soon as the 30% threshold is reached. Automated, no-call delivery.

Why choose Four Data?

From ideation to deployment: comprehensive support

Implement a propane / butane propane / butane remote reading solution is more than just installing a sensor. At Four Data, we provide end-to-end supportto guarantee sustainable results at scale.

Studio

Impulse

Service

+1200 customers, +14 countries deployed!

Today, our sensors and software solutions equip more than 60,000 tanks, cisterns and reservoirs across Europe.

📊 Key figures :

Launch your connected LPG project with Four Data 🚀

Ready to optimize the management of your storage systems with a connected level sensor? Four Data offers solutions tailored to your specific needs, whether for liquids, solids or other materials.

Let’s discuss your needs

We would be delighted to discuss your projects and level measurement requirements. Make an appointment today to talk to an expert from our team.

A customized, scalable solution

With Four Data, you benefit from a flexible, scalable solution. We support you throughout the integration and optimization of your inventory management processes.