Connected gauges for IBC

A connected gauge for intelligent monitoring to optimize management of your IBC tanks

Optimize your tank management with our connected monitoring solution. We enable you to monitor your tank levels and anticipate your needs, without manual intervention.

Intelligent, automated monitoring

Thanks to the integration of IoT connected sensors, we collect and analyze level information from your tanks, whether for water, fuel oil or any other industrial liquid. Our technology enables you to :

A solution tailored to your sector

Our expertise in connected supervision is aimed at professionals in industry, transport, energy and the environment, who want to make their equipment control more reliable and automated.

Understanding connected gauges for IBC

What is a connected gauge?

A connected IBC tank gauge is an IoT IoT level sensor designed to accurately measure the quantity of liquid contained in a tank. Installed directly on the tank, it transmits level indicators via communication protocols. LPWAN – Low Power Wide Area Network– such as NB-IoT, LoRa and Sigfox or GSM (ideal for rural areas!)

These gauges are used in many sectors, including industry, energy, the environment and logistics, wherefluid management is a strategic issue. Thanks to intelligent monitoring, companies can better anticipate their needs and secure their supplies.

Our remote monitoring service is based on these connected gauges and gives you centralized access to all your data via an intuitive platform. You benefit from optimized, automated tank management.

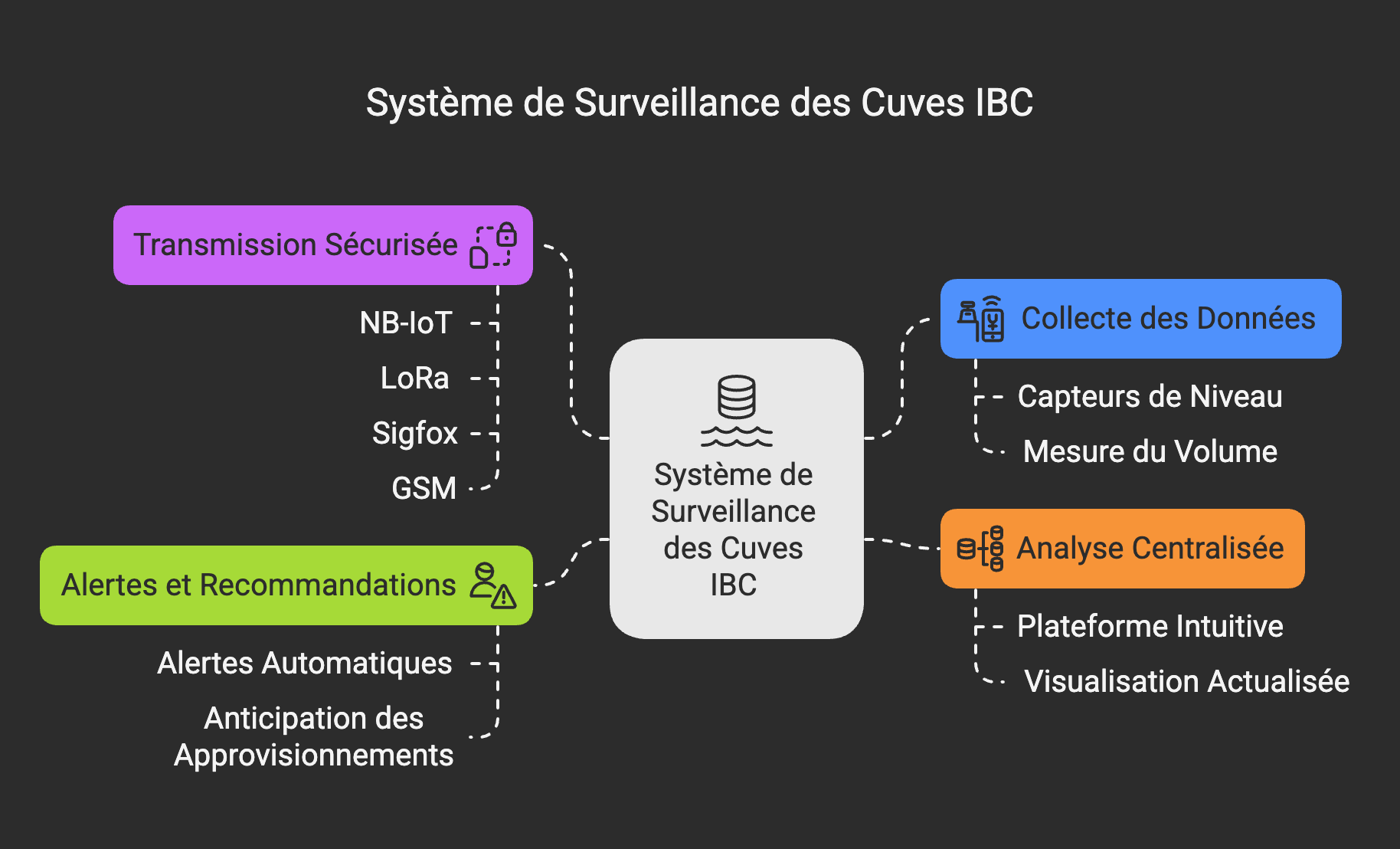

📡 How does our IBC tank monitoring service work?

Technology used: communicating sensors and supervision platform

Our monitoring service for IBC tanks is based on the integration of IoT level sensors already installed on your tanks or supplied by your service providers. Thanks to a connection NB-IoT, LoRa, Sigfox or GSMThese sensors collect and analyze liquid levels, improving inventory management and forecasting.

- 1

Data collection : Connected sensors (water level sensor, level probe, level detector) measure the volume of fluid stored in each IBC.

- 2

Secure transmission: Data is sent via a long-range IoT network (NB-IoT, LoRa, Sigfox, GSM), guaranteeing reliable connectivity without the need for manual intervention.

- 3

Centralized analysis: All information is aggregated and accessible via our intuitive platform, which provides an up-to-date visualization of liquid levels.

- 4

Alerts and recommendations: When the level reaches a critical threshold, an automatic alert is sent to anticipate supplies and avoid shortages or surpluses.

With our tank monitoring offer, you gain efficiency and peace of mind by optimizing your tank management effortlessly.

Automated monitoring and intelligent alerts

Our monitoring service enables you to track fluid levels in your industrial tanks on a regular basis. Thanks to connected sensors and our centralized management platform, you benefit from complete visibility of your stocks and intelligent alerts when needed.

📢 Automatic alerts for proactive management

- Customizable critical thresholds set minimum and maximum levels to suit your needs

- Instant notifications Receive alerts by email, SMS or via our interface in the event of abnormal variations.

- Prevent out-of-stock situations: anticipate replenishments with forecasts based on your data

- Anomaly identification Quickly detect leaks, overconsumption or abnormal fluctuations.

With these tools, you can optimize your tank management and reduce the risk of incidents or interruptions to your business.

Compatibility with different types of IBC tanks

Our monitoring solution is designed to fit a wide range of industrial tanks and vessels, whatever the fluid stored: water, fuel oil, chemicals, liquid foodstuffs, etc. We integrate data from various IoT-level sensors, whether using ultrasonic, pressure or flowmeter technologies.

📊 Compatibility table

| IBC tank type | Compatible liquids | Supported technologies |

|---|---|---|

| Plastic (HDPE) | Water, chemicals, food liquids | Ultrasonic sensor, IoT level sensor |

| Metal (stainless steel, steel) | Hydrocarbons, fuel oil, solvents | Pressure level switch |

| Opaque bowl | Light-sensitive products | Connected sensor with LoRa/Sigfox transmission |

| Underground tanks | Industrial and agricultural fluids | Level sensor with NB- IoT / GSM connection |

How to choose the best monitoring solution for your IBC tank?

Selection criteria: accuracy, connectivity, compatibility

Choosing the right IBC tank monitoring service is essential to ensure efficient inventory management and avoid supply interruptions. Here are the main criteria to consider:

Thanks to our expertise in IoT monitoring, we can help you choose and integrate the solution best suited to your business.

Comparison of solutions available on the market

There are several solutions for monitoring liquid levels in IBC tanks, but not all of them meet the same needs. Here’s a comparison of the main options available on the market:

📊 Comparative table of monitoring solutions

| Criteria | Traditional solutions (manual reading) | Connected sensor alone | IoT monitoring service (our approach) |

|---|---|---|---|

| Measurement accuracy | Low (visual estimation) | Medium to high | High (automated analysis) |

| Automatic alerts | ❌ No | ❌ No | ✅ Yes, notifications in case of critical threshold |

| Connectivity | None | Sensor-dependent | LoRa, Sigfox, NB-IoT, GSM, integrated PLC |

| Data analysis | ❌ No | ✅ Local data storage | ✅ Access to historical and forecast data |

| Ease of use | Average (manual reading required) | Varies according to sensor | ✅ Intuitive interface, remotely accessible |

| Overall cost | Low short-term | Medium | Long-term cost-effectiveness (inventory optimization) |

Why is our monitoring service the best choice?

Our IoT monitoring solution for IBC tanks stands out for its accuracy, flexibility and intuitive integration. Unlike stand-alone systems, we offer a complete platform that adapts to your existing sensors and provides detailed analysis of your fluid levels.

⚡ The concrete benefits of our service:

- Supports sensors already installed, avoiding additional investment.

- Automated alerts and notifications, for more responsive inventory management.

- Ergonomic user interface, accessible from computer, tablet or smartphone.

- Optimize costs and logistics, thanks to reliable, usable data.

Setting up and connecting to our IoT platform

Once the sensors are connected to our platform, set-up is quick and intuitive. Our interface enables centralized management of all your IBC tanks, with access to regularly updated data and advanced analysis tools.

🔧 Platform configuration in just a few steps :

- Secure connection: Access via web interface or mobile application.

- Setting alert thresholds: Definition of critical levels to avoid breakage or overflow.

- Interactive dashboard: At-a-glance monitoring of stored liquid levels and trends.

- Consumption history Access to past data for more detailed analysis and optimized planning.

With our IoT solution, you keep total control over your inventory and can effectively anticipate your needs.

Contact us for a demonstration

Try our no-obligation monitoring solution

Optimize your IBC tank management today with our IoT monitoring solution. Our platform enables you to monitor your stocks periodically, anticipate your needs and avoid supply shortages.

✅ Test our no-obligation solution and discover how it can be integrated into your existing operations. Thanks to rapid configuration and personalized support, you’ll immediately benefit from the advantages of connected monitoring.

📩 Contact us for a free demonstration and find out immediately how to optimize your tank management.

Make an appointment with an IoT expert

Our experts can help you optimize your tank management using IoT technologies and connected sensors. Whether you already have level sensors installed or would like to explore a new solution, we analyze your environment and specific constraints to propose the best approach.

📅 Make an appointment with one of our specialists to discuss your needs and find out how our monitoring solution can improve your liquid inventory management.